MPO and MTP cables serve as crucial components in high-speed data transmission systems. MPO, or Multi-Fiber Push-On, connectors feature a plastic design that can be less durable. In contrast, MTP connectors utilize a metal pin clamp, enhancing reliability and performance. These distinctions significantly impact their practical applications, particularly in data centers and telecommunications. As demand rises, the MPO/MTP patch cord market is projected to grow from USD 1.41 billion in 2024 to USD 1.49 billion in 2025, reflecting the increasing adoption of these technologies.

Key Takeaways

- MPO connectors are standard multi-fiber connectors, while MTP® connectors are advanced versions with enhanced features.

- MTP® connectors offer lower insertion loss, improving signal quality for high-speed data transmission.

- MPO connectors support fiber counts from 12 to 144, making them scalable for various network needs.

- MTP® connectors have a robust metal pin clamp, enhancing durability and alignment during connections.

- Regular maintenance of MPO and MTP cables includes inspecting for damage and cleaning connectors to ensure optimal performance.

- MTP® connectors are backward compatible with MPO systems, allowing for easy upgrades without overhauling existing infrastructure.

- Investing in MTP® connectors can lead to long-term cost savings due to reduced maintenance and improved performance.

- Choosing between MPO and MTP® connectors depends on your network’s performance needs and budget considerations.

What are MPO Connectors?

Definition of MPO

MPO stands for "Multi-Fiber Push-On." This connector type plays a vital role in high-density fiber optic networks. According to international cabling standards, MPO connectors adhere to specific guidelines set by organizations such as the International Electrotechnical Commission (IEC) and the Telecommunications Industry Association (TIA). The IEC defines the standard IEC-61754-7 for MPO connectors, while the TIA has established the TIA-604-5 standard, also known as the Fiber Optic Connector Intermateability Standard (FOCSI) 5. These standards ensure compatibility and reliability across various applications.

Key Features of MPO Connectors

MPO connectors offer several technical features that enhance their performance and usability in modern networking environments. Below is a summary of the key features:

| Feature | Description |

|---|---|

| Industry Standards | Defined by IEC 61754-7 and EIA/TIA-604-5 (FOCIS 5) for compatibility and reliability. |

| Fiber Count | Supports 12 to 144 fibers for scalability in network infrastructures. |

| Connection Mechanism | Push-on connection simplifies installation and fiber management. |

| Insertion Loss | Low insertion loss maintained through precise core alignment and high-quality ferrules. |

| Return Loss | Enhanced return loss performance critical for high-speed networks. |

| Pre-terminated Cables | Factory-tested for rapid deployment and reduced installation errors. |

| Advanced Fiber Designs | Low attenuation for high data transmission quality and plug-and-play installation. |

| Scalability and Flexibility | Designed for evolving network infrastructures with seamless upgrades and expansions. |

| Performance Metrics | High-speed data transmission capabilities for 40G, 100G, and beyond. |

| Cable Management | Simplifies maintenance and reduces space consumption. |

MPO connectors provide outstanding scalability and flexibility for evolving network infrastructures. They support multiple fiber counts, ranging from 12 to 144 fibers, which accommodates both current and future bandwidth needs. The push-on connection mechanism simplifies installation and fiber management, making it easier for technicians to deploy and maintain networks. Standardized connectors ensure seamless upgrades and expansions, while pre-terminated designs allow for quick deployment and minimal downtime.

What are MTP® Connectors?

Definition of MTP®

MTP® stands for "Mechanical Transfer Push-On." This connector type represents an advanced version of the standard MPO connector. MTP® connectors are designed to meet the demands of high-performance fiber optic networks. They comply with strict industry standards, ensuring compatibility and reliability across various applications. MTP® connectors are particularly favored in environments requiring high-density connections, such as data centers and telecommunications.

Key Features of MTP® Connectors

MTP® connectors offer several distinguishing features that enhance their performance compared to standard MPO connectors. Below is a summary of these key features:

| Feature | Description |

|---|---|

| Outer Housing | MTP® connectors have a removable housing, allowing for rework and testing. |

| Ferrule | The floating ferrule design improves mechanical properties and stability under load. |

| Guide Pins | MTP® connectors utilize stainless steel elliptical guide pins to reduce wear and improve alignment. |

| Pin Clamp | Metal pin clamps in MTP® connectors prevent damage and ensure durability. |

| Insertion Loss | MTP® connectors achieve lower insertion loss, improving optical performance. |

MTP® connectors incorporate proprietary technologies that further enhance their performance. For instance, the floating ferrules allow slight movement during mating, which improves mechanical performance. The stainless steel guide pins enhance alignment and reduce wear during connection. Additionally, the elliptical-shaped tips minimize the risk of damage during the mating process. MTP® Elite connectors achieve ultra-low insertion loss, around 0.10 dB, ensuring high signal integrity. Stringent manufacturing tolerances guarantee consistent performance, even at higher fiber counts. Furthermore, MTP® connectors can withstand over 1,000 mating cycles without significant performance degradation.

Mechanical Design Comparison of MPO and MTP

Pin Clamps

Pin clamps play a crucial role in the durability and alignment of fiber optic connectors. MTP connectors utilize a robust metal pin clamp, which significantly reduces the risk of damage during repeated mating cycles. This design ensures a tight clasp, maintaining alignment accuracy. In contrast, MPO connectors typically feature a plastic pin clamp that is more prone to breakage. The fragility of the plastic clamp can lead to alignment issues, especially with frequent connections.

- MTP connectors maintain alignment accuracy through a floating ferrule and elliptical guide pins.

- MPO connectors may experience alignment issues due to the fragility of their plastic pin clamps.

Floating Ferrules

The floating ferrule design in MTP connectors enhances performance by allowing slight movement during mating. This flexibility is essential for applications involving direct connections to active transceivers. The MTP connector’s design mitigates issues such as dust accumulation, which can enhance performance reliability. The thermoplastic material used in MTP connectors maintains a consistent diameter for guide holes, leading to a more reliable physical connection.

- The floating ferrule feature is crucial for applications involving direct connections to active transceivers.

- MTP connectors are preferred in applications where connectors plug directly into active devices due to their ability to maintain contact under load.

In contrast, the original design of MPO connectors is prone to moisture absorption, which can affect performance over time. The immobile MT ferrule of the MPO connector does not provide the same level of flexibility, potentially leading to increased insertion loss.

Guide Pins

Guide pins are another critical component that influences the mating accuracy of fiber optic connectors. MTP connectors feature guide pin designs with tighter tolerances compared to MPO connectors. This results in improved alignment and lower insertion loss when connecting fiber optic cables. Enhanced precision is vital for maintaining signal integrity, particularly in high-density applications.

- MTP connectors have elliptical guide pins that improve alignment and reduce wear.

- MPO connectors use inferior plastic guide pins, which can lead to misalignment and increased insertion loss.

The superior design of MTP connectors ensures that they perform reliably in demanding environments, making them the preferred choice for modern networking applications.

Optical Performance of MPO and MTP® Cables

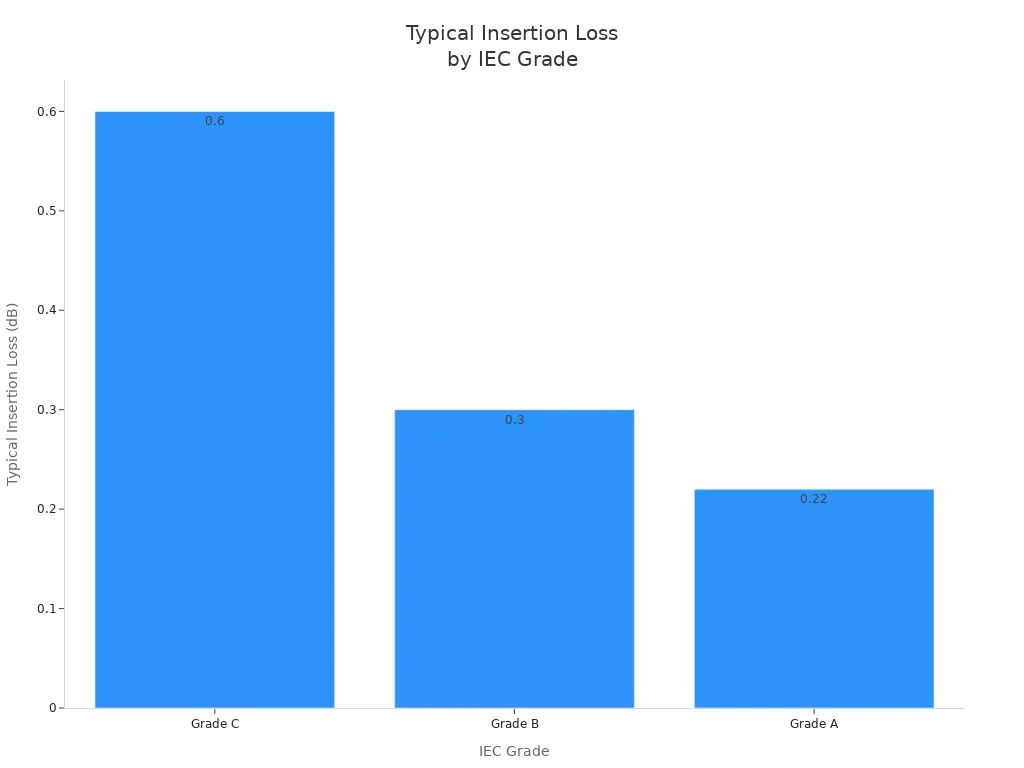

Insertion Loss

Insertion loss refers to the amount of signal power lost when light passes through a connector. This parameter is critical in determining the overall performance of fiber optic systems. MTP connectors typically exhibit lower insertion loss compared to standard MPO connectors.

The following table summarizes the typical insertion loss values for different grades of connectors as defined by the International Electrotechnical Commission (IEC):

| Grade (IEC) | Max IL (dB) | Typical IL (dB) | Max RL (dB) |

|---|---|---|---|

| C | 0.75 | 0.60 | −30 |

| B | 0.35 | 0.30 | −50 |

| A | 0.25 | 0.22 | −60 |

Elite-grade MTP connectors typically achieve insertion loss values ranging from 0.20 to 0.25 dB. In contrast, standard MPO connectors generally have higher insertion loss values, ranging from 0.40 to 0.75 dB. The differences in insertion loss, while not vast, significantly impact performance, especially in high-speed transmission scenarios. MTP connectors ensure that signals experience less attenuation, making them more effective for long-distance data transmission.

Reliability Factors

Reliability is paramount in high-density network environments. MTP cables are designed with features that ensure lower insertion loss, which is critical for maintaining high signal integrity in dense data communication links. The following factors contribute to the reliability of MPO and MTP cables:

- MTP connectors facilitate faster network deployment, reducing installation time and labor costs.

- High-quality MTP MPO cables ensure stability and reliability of network performance, minimizing risks of signal loss.

- The ability to handle bending without signal loss is crucial in high-density environments to maintain signal integrity.

In addition, regular maintenance practices can enhance the longevity and performance of these cables. Best practices include:

- Regular examination for physical damages.

- Cleaning connectors using specialized tools.

- Monitoring network performance metrics to detect issues early.

By adhering to these practices, network administrators can ensure optimal performance and reliability of MPO and MTP cables over time.

Practical Applications of MPO and MTP® Cables

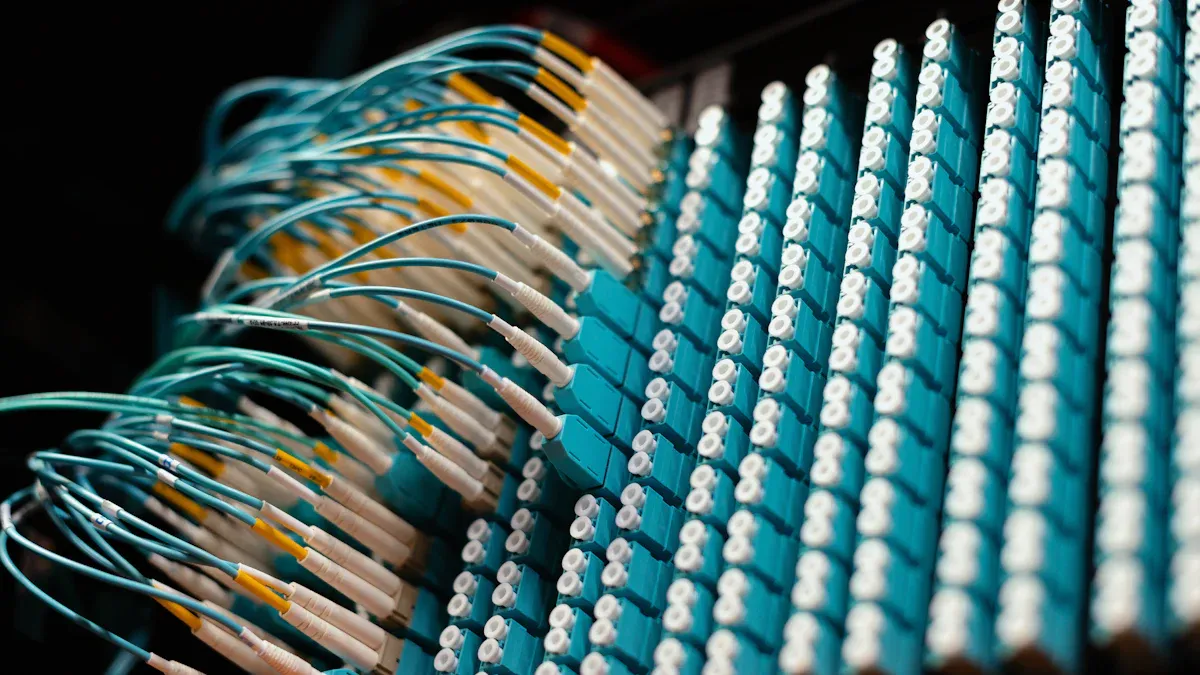

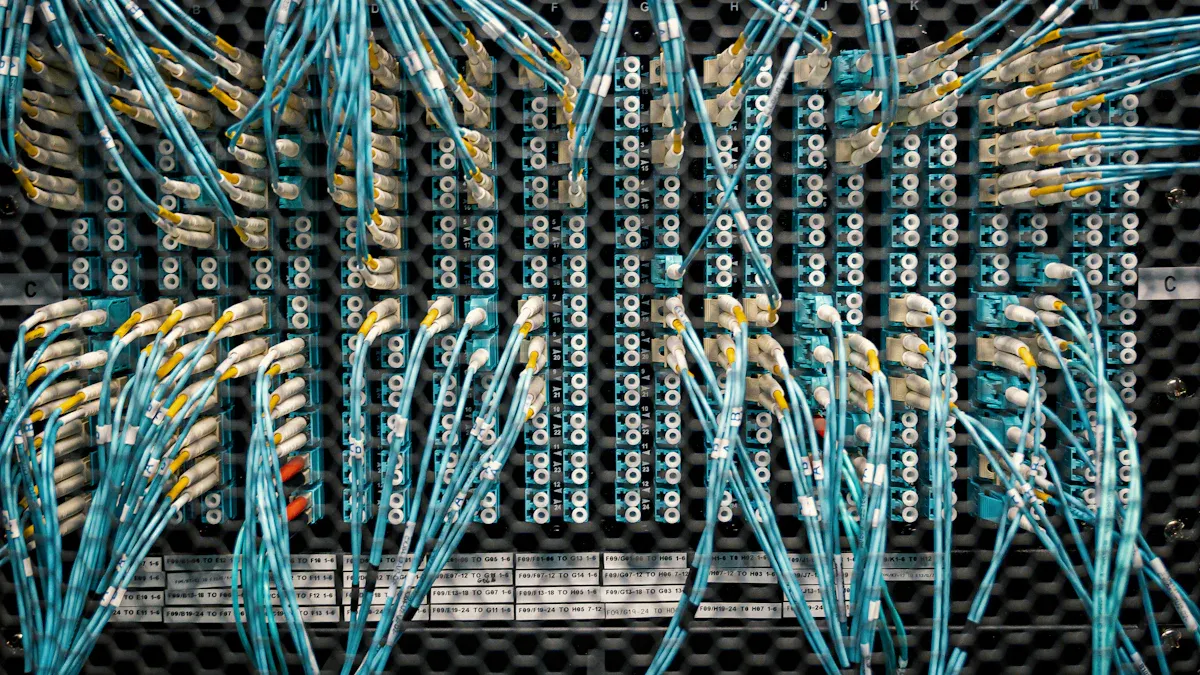

MPO and MTP cables play a vital role in various sectors, particularly in data centers and telecommunications. Their design and performance characteristics make them ideal for high-density environments where efficient data transmission is crucial.

Data Center Usage

In data centers, MPO and MTP cables are essential for supporting high-speed data transmission. Common architectures utilize MPO/MTP trunk and breakout cables, which provide several benefits:

- Supports high-speed data transmission for 100G and 400G networks.

- Enhances bandwidth and space efficiency in data centers.

- Facilitates easier management and installation of cabling systems.

These features allow data centers to optimize their infrastructure while accommodating growing bandwidth demands.

Telecommunications

MPO and MTP cables are crucial in telecommunications networks, especially in high-density cabling setups. They facilitate efficient data transmission, with MTP connectors providing superior performance metrics. For instance, MTP connectors achieve lower insertion loss, around 0.15 dB, compared to standard MPO connectors, which have an insertion loss of approximately 0.35 dB. This reduced signal loss makes MTP connectors particularly suitable for high-speed applications like 100G and 400G, where maintaining signal integrity is essential.

Other Industries

MPO and MTP cables also find applications in various other industries. The following table highlights specific applications across different sectors:

| Industry | Specific Applications |

|---|---|

| Broadcast | Data centers, telecom centers, enterprise networks |

| Healthcare | Data centers, telecom centers, enterprise networks |

| Data Center SAN | High-density modular cabling for easy reconfiguration |

| Co-location Data Center | High scalability and flexibility in network design |

| Enterprise Network | Quick installation with plug-and-play capabilities |

| Telecom Center | Large capacity and high performance for high-density racks |

These diverse applications demonstrate the versatility of MPO and MTP cables, making them indispensable in modern networking environments.

Advantages of MTP® Connectors

Enhanced Performance

MTP® connectors offer significant performance advantages over standard MPO connectors. Their design incorporates advanced features that enhance both optical and mechanical characteristics. The following table summarizes key performance metrics:

| Characteristic | MTP® Connectors | MPO Connectors |

|---|---|---|

| Insertion Loss | Reduced due to floating ferrule design | Higher due to tighter tolerances |

| Return Loss | Better performance | Varies by manufacturer |

| Alignment Pin Accuracy | Very accurate, ensuring strong connections | Less consistent |

| Detachability | Easier maintenance and polarity reversal | Requires special tools |

| Speed Support | Up to 400Gb/s | Slower than MTP® |

MTP® connectors maintain lower insertion loss, which is crucial for high-speed data transmission. They also feature improved alignment pin accuracy, ensuring strong connections that minimize signal degradation. Additionally, MTP® connectors allow for easier maintenance and polarity reversal, which simplifies network management.

Moreover, MTP® connectors are backward compatible with MPO connectors. This compatibility allows for seamless integration into existing MPO network designs, making upgrades straightforward without requiring a complete system overhaul.

Cost-Effectiveness in the Long Run

Investing in MTP® connectors can lead to substantial long-term cost savings, especially in large-scale networks. Here are some key factors contributing to their cost-effectiveness:

- In high-density cabling environments, MTP connectors can lead to significant cost savings due to their multi-fiber nature.

- MTP connectors reduce required rack space and simplify cable management, contributing to long-term savings.

- The consolidation of multiple fibers in a single MTP connector leads to a lower Total Cost of Ownership (TCO).

- MTP connectors’ ease of maintenance and potential to reduce downtime contribute to long-term operational efficiency and cost savings.

Real-world examples illustrate these benefits. A major cloud service provider upgraded to MTP cables for 100G applications, resulting in reduced installation time and improved performance. Similarly, Acme Corporation upgraded its fiber optic network using MTP/MPO Key Up to Key Up Panelmount Fiber Optic Coupler, addressing bandwidth needs while minimizing disruptions.

MPO and MTP® cables serve distinct roles in modern networking. The key differences lie in their design and performance capabilities. MTP® connectors offer several advantages, including:

- High fiber density, allowing simultaneous connections of multiple strands.

- Ease of installation, which simplifies setup and maintenance.

- Improved performance with lower insertion loss for high-speed data transmission.

Organizations should consider their specific needs when choosing between MPO and MTP®. MTP® connectors excel in high-performance environments, while MPO connectors may be more cost-effective for less demanding applications. Prioritizing performance, scalability, and budget will lead to the best choice for any network infrastructure.

FAQ

What is the main difference between MPO and MTP® connectors?

MPO connectors are standard multi-fiber connectors, while MTP® connectors are an advanced version with enhanced features. MTP® connectors offer lower insertion loss and improved durability due to their metal pin clamps and floating ferrule design.

Can MTP® connectors be used with MPO systems?

Yes, MTP® connectors are backward compatible with MPO systems. This compatibility allows users to integrate MTP® connectors into existing MPO networks without requiring a complete overhaul of the infrastructure.

What applications benefit most from MTP® connectors?

MTP® connectors excel in high-density environments, such as data centers and telecommunications. Their low insertion loss and high performance make them ideal for applications requiring fast data transmission, like 100G and 400G networks.

How do I maintain MPO and MTP® cables?

Regular maintenance includes inspecting cables for physical damage, cleaning connectors with specialized tools, and monitoring network performance metrics. These practices help ensure optimal performance and longevity of the cables.

What is the typical fiber count supported by MPO and MTP® connectors?

MPO connectors support fiber counts ranging from 12 to 144 fibers. MTP® connectors also support similar fiber counts, making both options scalable for evolving network infrastructures.

Are MTP® connectors more expensive than MPO connectors?

MTP® connectors may have a higher initial cost due to their advanced features. However, their long-term benefits, such as lower insertion loss and reduced maintenance, can lead to overall cost savings in large-scale networks.

How do I choose between MPO and MTP® connectors?

Consider your specific network requirements. If high performance and low insertion loss are critical, MTP® connectors are preferable. For less demanding applications, MPO connectors may provide a more cost-effective solution.

What is the lifespan of MPO and MTP® connectors?

Both MPO and MTP® connectors can last for many years with proper care. MTP® connectors, with their robust design, can withstand over 1,000 mating cycles, ensuring long-term reliability in high-density environments.