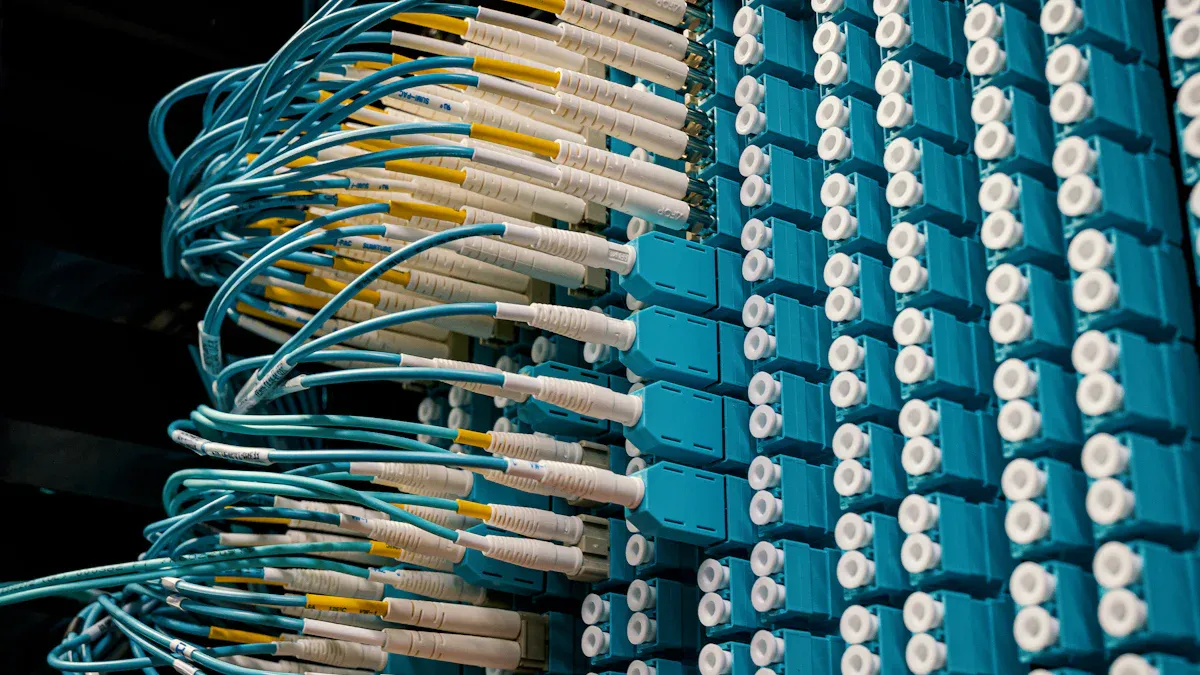

Data centers demand peak performance. Optimized MPO trunk connectivity achieves this goal. MPO trunk assemblies play a critical role in high-density, high-speed network infrastructures. Experts project the MPO Trunk market will grow at a 14.00% compound annual growth rate from 2025 to 2032. It will increase from $850 million in 2024 to $2.4 billion by 2032. This growth highlights the importance of strategic MPO solutions. These solutions ensure reliability and future scalability. Proper use of components like an MPO Adapter or an MPO Breakout Harness Cable, and an MPO Harness Cable, is essential.

Key Takeaways

- Choose MPO trunk parts carefully. This ensures your network works well and can grow later.

- Understand MPO polarity methods. This makes sure signals flow correctly and prevents network problems.

- Use high-quality MPO cables. This makes your data center network reliable and last a long time.

- Install MPO cables the right way. This protects the cables and keeps them working well.

- Test MPO connections thoroughly. This checks that your network works as it should.

- Plan MPO systems for future growth. This helps your data center handle more data later.

- Clean MPO connectors often. This keeps your network running smoothly and prevents issues.

1. Strategic Selection of MPO Trunk Components

Data center managers must carefully select MPO trunk components. This ensures optimal performance and future-proof infrastructure. The right choices impact network reliability and scalability.

Understanding MPO Connector Types and Standards

MPO vs. MTP Connectors for MPO Trunk Assemblies

MPO and MTP connectors appear similar but possess distinct performance characteristics. MTP connectors offer superior mechanical and optical performance. They feature metal pin clamps, which minimize breakage and protect fiber strands with a special spring mechanism. Standard MPO connectors typically use plastic clamps. MTP connectors also incorporate a floating ferrule. This maintains physical contact even under cable strain, improving alignment and precision during mating. MPO ferrules remain immobile. Furthermore, MTP connectors utilize elliptical guide pins. These significantly reduce damage and debris generation during mating compared to MPO’s flat-ended guide pins. MTP connectors also include a removable housing. This allows for easy re-polishing or re-working without replacing the entire assembly, offering greater versatility.

Keying Mechanisms and Their Impact on MPO Trunk Polarity

Keying mechanisms on MPO connectors ensure correct fiber alignment. A small key on the connector body dictates its orientation. Understanding key-up and key-down positions is crucial for managing polarity. Incorrect keying leads to polarity mismatches, preventing proper signal transmission.

Connector Grades and Performance Tiers for MPO Trunk Solutions

MPO connectors come in various grades, such as "Standard" and "Elite." Elite-grade connectors offer lower insertion loss, which is critical for high-speed, long-distance links. Selecting the appropriate grade directly impacts the overall performance and reliability of the MPO trunk solution.

Fiber Count and Configuration for MPO Trunk Cables

Optimizing 12-Fiber and 24-Fiber MPO Trunk Deployments

Data centers frequently deploy 12-fiber and 24-fiber MPO trunk cables. These configurations efficiently support 40G and 100G Ethernet applications. A 12-fiber MPO often supports 40G (4x10G lanes), while 24-fiber MPO cables can support 100G (10x10G or 4x25G lanes).

Considerations for Higher Fiber Count MPO Trunk Assemblies

For high-density fiber networks, MPO trunk cables are available in higher fiber counts. Common options include 48-fiber, 72-fiber, and 144-fiber configurations. These assemblies are ideal for trunking and cascading distribution, providing flexibility and scalability. B Polarity is a key configuration method for these high-density deployments. It ensures proper signal path alignment by crossing transmit (Tx) and receive (Rx) pairs.

Custom MPO Trunk Configurations for Specific Data Center Needs

Many data centers require custom MPO trunk configurations. Tailored lengths, specific breakout configurations, and unique jacket types optimize cable management and airflow. Custom solutions ensure a perfect fit for unique infrastructure requirements.

Choosing the Right Fiber Type for MPO Trunk Connectivity

Single-Mode MPO Trunk Cables for Long-Haul and High Bandwidth

Single-mode MPO cables excel in long-haul and high-bandwidth applications. They transmit light exclusively in one plane, allowing for distances up to kilometers. This makes them suitable for metropolitan area networks (MANs) and passive optical networks (PONs).

| Feature | Single-mode MPO Cables | Multimode MPO Cables |

|---|---|---|

| Core Diameter | Approximately 8 to 10 microns | Approximately 50 or 62.5 microns |

| Light Propagation | Exclusively in one plane/mode | Multicore light can traverse |

| Transmission Dist. | Up to kilometers | Up to 600 meters at high speed |

| Bandwidth | Increased capabilities | High speed |

| Applications | Long-haul and telecommunication transmission | LAN and database |

Multimode MPO Trunk Cables for Shorter Reach and Cost-Effectiveness

Multimode MPO cables are a cost-effective solution for shorter distances within the data center. They support high-speed data transmission up to 600 meters. These cables are commonly used for local area networks (LANs) and database connections.

OS2, OM3, OM4, and OM5 Fiber Specifications for MPO Trunk Performance

Fiber specifications define performance. OS2 represents single-mode fiber, suitable for extended distances. OM3, OM4, and OM5 are multimode fiber types. OM3 supports 10G Ethernet up to 300 meters. OM4 extends 10G to 550 meters and supports 40G/100G. OM5, a wideband multimode fiber, further enhances performance for short-reach 400G applications.

2. Mastering MPO Trunk Polarity Management

Effective polarity management is crucial for MPO trunk connectivity. It ensures proper signal flow from transmit to receive. Incorrect polarity leads to communication failures.

Decoding MPO Polarity Methods for Seamless Connectivity

The TIA 568 standard defines three primary MPO polarity methods. These methods use specific MTP® trunk cables (Type A, Type B, or Type C) and duplex patch cables (A-to-A or A-to-B). They ensure correct fiber circuit polarity.

Type A (Straight-Through) MPO Trunk Polarity Explained

Method A uses a Type A trunk cable. This cable connects MTP® modules. It requires standard A-to-B type duplex patch cables on both ends of the link. For duplex applications, Method A requires an A-A duplex patch cord at one end. This flips the transceiver-receiver from Position 1 (Tx) to Position 2 (Rx). An A-B patch cord is needed at the other end. For 40/100 Gig applications, Method A uses a Type A MPO patch cord on one end and a Type B MPO patch cord on the other end. This connects patch panel ports to transceiver ports. Only one Type B patch cord is permitted in the channel.

Type B (Cross-Over) MPO Trunk Polarity for Transceiver Matching

Method B employs a Type B trunk cable. This cable has reversed fiber positions at each end. Standard A-to-B type duplex patch cables are used on both sides. For duplex applications, Method B uses A-B duplex patch cords on both ends. No transceiver-receiver flip is needed. For 40/100 Gig applications, Method B employs Type B MPO patch cords on both ends. This connects patch panel ports to their respective ports. This method is often recommended. It uses the same patch cord type for both duplex and parallel applications.

Type C (Pair-Flipped) MPO Trunk Polarity in Specific Scenarios

Method C utilizes a pair-reversed trunk cable. This cable links MTP® modules. Similar to Method A and B, standard A-to-B type duplex patch cables are used at both ends.

Ensuring End-to-End Compatibility with MPO Trunk Polarity

Proper polarity ensures seamless data transmission. Data center operators must maintain consistency.

Matching MPO Trunk Polarity to Transceiver Requirements

Transceivers have specific transmit (Tx) and receive (Rx) port configurations. The MPO trunk polarity must align with these requirements. A mismatch prevents signal flow. Always verify transceiver specifications before deployment.

Documenting MPO Trunk Polarity Schemes for Future Reference

Comprehensive documentation of polarity schemes is essential. This includes cable types, connector types, and the chosen polarity method. Clear records simplify future troubleshooting and upgrades.

Avoiding Polarity Mismatches in MPO Trunk Deployments

Careful planning and consistent labeling prevent polarity errors. Technicians should follow established installation procedures. Double-checking connections before activation minimizes costly downtime.

Tools and Techniques for MPO Trunk Polarity Verification

Verification tools confirm correct polarity. They ensure network reliability.

Utilizing Visual Fault Locators for MPO Trunk Polarity Checks

Visual Fault Locators (VFLs) inject visible light into the fiber. Technicians can visually trace the light path. This helps confirm fiber continuity and identify polarity.

Advanced Optical Loss Test Sets for MPO Trunk Polarity Confirmation

Optical Loss Test Sets (OLTS) measure insertion loss and verify polarity. These devices provide precise measurements. They confirm the integrity of the fiber link.

Best Practices for MPO Trunk Polarity Troubleshooting

When issues arise, technicians should systematically check each connection. They verify cable types and patch cord configurations. Consulting documentation helps resolve polarity problems efficiently.

3. Prioritizing High-Quality MPO Trunk Cable Selection

Selecting high-quality MPO trunk cables is fundamental for data center performance. Cable construction, termination methods, and environmental resilience directly impact network reliability and longevity.

Fiber Optic Cable Construction and Durability for MPO Trunk Use

Cable Jacket Ratings: Plenum, Riser, and LSZH for MPO Trunk Safety

Cable jacket ratings ensure safety and compliance. Different environments require specific jacket types.

| Jacket Type | Description | Safety Implications |

|---|---|---|

| Plenum-Rated | Designed for air-handling spaces like ceilings or ducts. | High fire-resistance and low smoke emission; often required by building codes. |

| Riser-Rated | Suitable for vertical runs between floors. | Offers fire resistance, but less stringent than plenum-rated cables. |

| LSZH (Low Smoke Zero Halogen) | Produces minimal smoke and no toxic halogen gases when burned. | Ideal for indoor areas with strict safety requirements, such as data centers and public buildings. |

| PVC Jacket | Common and cost-effective for indoor use. | Flexible and easy to install, but less resistant to fire and chemicals. |

Plenum-rated cables, including those supporting MPO-style connectivity, are ideal for trunk, LAN, data center, and 40/100GbE applications. They require high density, small size, and tight bend radii. These cables are suitable for installation in ducts, plenums, risers, and air-handling spaces. Their small diameter saves space, improves cable management, and enhances cooling efficiency in data centers.

Bend Insensitive Fiber (BIF) Benefits for MPO Trunk Routing

Bend-insensitive fibers (BIF) offer significant advantages in confined data center spaces.

- Tighter Bending Radii: BIF allows for significantly smaller bend radii, as tight as 7.5 mm under load, compared to traditional fibers. This is crucial for routing in confined spaces like cable trays and patch panels.

- Improved Routing: BIF facilitates easier routing in restricted areas such as cable trays, patch panels, and equipment racks. These are common in high-density data centers.

- Reduced Signal Attenuation: The risk of signal loss during installation or reconfiguration is minimized. The fiber withstands tighter bends without performance degradation.

- Enhanced Flexibility: This technology greatly enhances flexibility and efficiency during installation. This is particularly beneficial in high-density data centers where space is limited and cable management is complex.

Armored MPO Trunk Cables for Enhanced Protection

Armored cables provide superior physical protection. They feature a metallic layer beneath the outer jacket. This protects against crushing, rodents, and other physical damage. Data centers often use them in harsh environments or areas requiring extra durability.

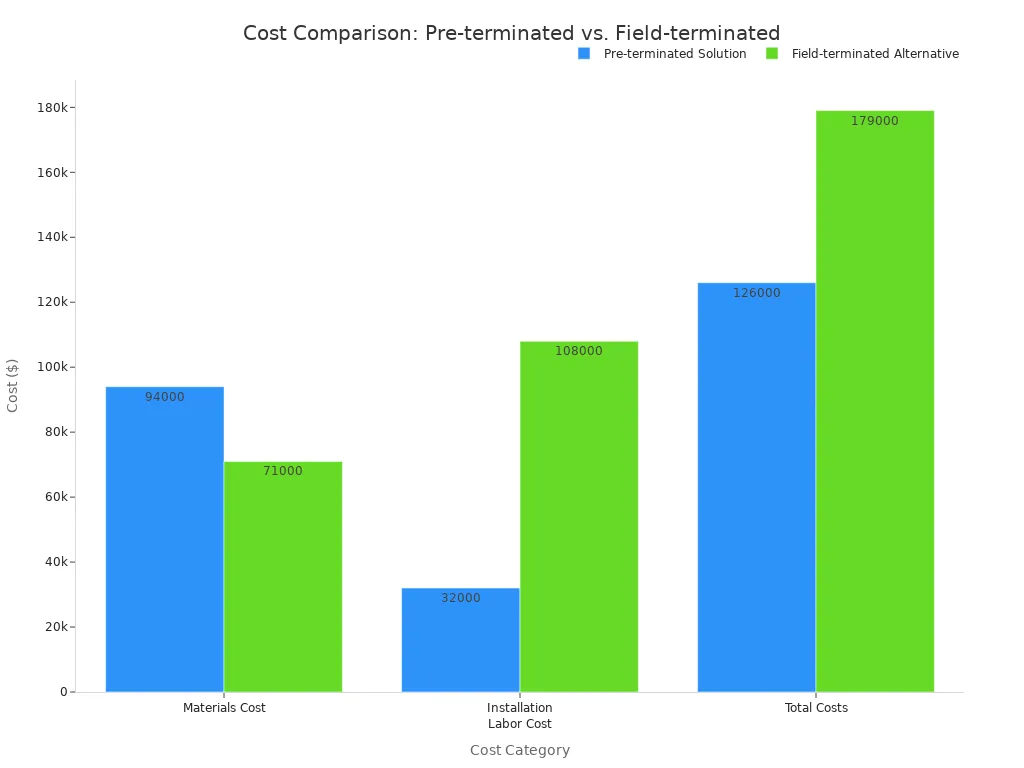

Pre-terminated vs. Field-terminated MPO Trunk Assemblies

Advantages of Pre-terminated MPO Trunk Cables for Rapid Deployment

Pre-terminated MTP systems significantly reduce data center construction timelines. A typical 800-fiber deployment, which might take over 120 hours for field termination, can be completed in 30-40 hours using pre-terminated components. These factory-produced cables arrive with connectors installed, polished, and tested to guaranteed specifications. This ensures higher quality assurance. Factory environments enable automated polishing and inspection, achieving <0.35dB insertion loss per mating pair. Field-terminated connections rarely match this consistency (0.2dB to 0.8dB) due to technician skill and environmental conditions.

| Cost Category | Pre-terminated Solution | Field-terminated Alternative |

|---|---|---|

| Materials Cost | $94,000 | $71,000 |

| Installation Labor Cost | $32,000 (384 hours) | $108,000 (1,260 hours) |

| Total Costs | $126,000 | $179,000 |

| Savings (Pre-terminated) | $53,000 | N/A |

When Field Termination is Necessary for MPO Trunk Customization

The main trade-off for pre-terminated systems is flexibility. They require accurate length planning. Custom lengths are available, but they come with lead times of 2-4 weeks. Organizations with predictable requirements and sufficient planning time benefit greatly from pre-terminated approaches. Conversely, those facing uncertain layouts or rapid deployment schedules may need the flexibility of field-terminated solutions. This is despite the sacrifices in performance and consistency.

Quality Control in Pre-terminated MPO Trunk Manufacturing

Quality control is paramount for pre-terminated MPO trunk cables. A critical measure is 100% factory pre-termination and testing. This process ensures optimal transfer performance and minimizes installation errors. It leads to ultra-fast deployment in data centers and telecom networks.

- Precision Polishing and High Standards of Quality Prevention Methods: These advanced manufacturing processes are crucial for improving component efficiency. They reduce flaws and ensure an unobstructed optical path.

- Quality Components: The use of high-quality ferrules and alignment pin assemblies directly impacts the minimization of insertion loss.

- Precision of Details and Technology Incorporation: These factors contribute to low insertion loss in MPO connectors. This is vital for high-speed and dependable fiber optic networks.

Environmental Considerations for MPO Trunk Cable Performance

Temperature and Humidity Impact on MPO Trunk Longevity

Environmental factors significantly impact fiber optic performance. High or low temperatures and humidity levels can negatively affect cables. Good cable management and protection practices are recommended for installation sites with these conditions.

| Condition | Temperature Range (°C) |

|---|---|

| Operating Temperature | -40 ~ +85 |

| Storage Temperature | -20 ~ +70 |

Temperature fluctuations impact connector performance. Data centers with stable environments of 18-27°C (64-80°F) typically do not thermally stress connectors. For edge computing in less controlled environments, where temperatures can range from -20°C to +60°C, MTP connectors made with thermoplastic materials are beneficial. They maintain consistent guide hole diameters despite temperature changes. Standard MPO connectors using thermoset compounds can absorb moisture and degrade under such conditions.

UV Resistance for Outdoor or Exposed MPO Trunk Applications

UV resistance is crucial for cables exposed to sunlight. Outdoor MPO trunk applications require jackets designed to withstand ultraviolet radiation. This prevents material degradation and ensures long-term performance.

Chemical Resistance for Industrial MPO Trunk Environments

Industrial environments often expose cables to various chemicals. Chemical-resistant jackets protect the fiber from corrosive substances. This maintains signal integrity and extends the cable’s lifespan in such demanding settings.

4. Implementing Best Practices for MPO Trunk Installation

Proper installation practices are essential for the long-term reliability and performance of MPO trunk connectivity. Careful handling and adherence to industry standards prevent common issues.

Proper MPO Trunk Cable Routing and Management

Effective cable routing and management protect fiber integrity and simplify maintenance.

Avoiding Tight Bends and Kinks in MPO Trunk Pathways

Technicians must adhere to the manufacturer’s minimum bend radius specifications. For example, single-mode cables require 30mm, and multi-mode cables need 10mm. This prevents micro-bends and signal degradation. Respecting the minimum bend radius also prevents permanent damage to the fibers.

Utilizing Cable Trays, Ducts, and Raceways for MPO Trunk Protection

Utilize cable trays, ducts, and raceways. These structures provide organized pathways. They protect cables from physical damage and maintain the correct bend radius. This simplifies maintenance and upgrades.

Segregating MPO Trunk Cables from Power Cables

Segregate MPO trunk cables from power cables. This prevents electromagnetic interference (EMI) that can degrade signal quality. Proper separation ensures optimal data transmission.

MPO Connector Handling and Cleaning Protocols

Maintaining clean MPO connectors is critical for optimal optical performance.

Importance of Contamination Prevention for MPO Trunk Performance

Preventing contamination is crucial. Dust and contaminants pose significant threats. Sources include manufacturing residue in dust caps, transfer during mating, environmental exposure, and improper handling. MPO connectors present unique cleaning challenges. They feature a larger rectangular ferrule, guide-pins and holes, multiple fiber ends, and fiber protrusion. These characteristics demand specialized cleaning tools and procedures. Contaminating particles in guide-pin holes can prevent good physical contact between fiber ends.

Recommended Cleaning Tools and Techniques for MPO Connectors

Recommended cleaning tools include dust removers, inspection scopes, fiber optic cleaning fluid, lint-free wipes, cleaning sticks, MPO click-to-clean tools, and MPO cleaning cassettes. For effective cleaning, technicians first clean the work area. They then inspect the end face before cleaning. They use a wet-to-dry method, employing cleaning sticks or MPO click-to-clean tools. For example, with a click-to-clean tool, technicians insert it into the connector until an audible click is heard, then remove it.

Inspection Before and After Cleaning MPO Trunk End-Faces

Always inspect the connector end-face before and after cleaning. Use an inspection microscope with an MPO probe tip. Adhere to IEC 61300-3-35 pass/fail criteria. This ensures no contaminants remain. If contamination persists, repeat the cleaning and inspection process.

Strain Relief and Physical Protection for MPO Trunk Assemblies

Proper strain relief and physical protection extend the lifespan of MPO assemblies.

Securing MPO Trunk Connectors and Cables at Termination Points

Secure MPO trunk connectors and cables at termination points. Technicians must verify full seating and latching of connectors. Use boots on MPO connectors. Keep strain relief components readily available. These prevent cable integrity loss and excessive bending at termination points.

Protecting MPO Trunk Cables Against Physical Damage and Stress

Protect MPO trunk cables against physical damage and stress. Avoid bending, twisting, or pulling MPO cables. This protects internal fibers. MTP cables feature a minimum bend radius of 7.50mm. This allows routing through high-density hardware without compromising performance or long-term reliability.

Proper Coiling and Storage of Excess MPO Trunk Cable Length

Properly coil and store excess MPO trunk cable length. This prevents tangles, kinks, and accidental damage. Use appropriate cable management accessories to maintain organization.

5. Conducting Thorough MPO Trunk Testing and Certification

Thorough testing and certification are crucial for validating MPO trunk performance. These steps ensure network reliability and compliance with industry standards. Proper testing identifies potential issues before they impact operations.

Essential Testing Parameters for MPO Trunk Performance

Technicians measure several key parameters to assess MPO trunk performance. These measurements confirm the integrity of the fiber optic links.

Insertion Loss Measurement for MPO Trunk Links

Insertion Loss (IL) quantifies the optical signal loss as it passes through a fiber optic component. Lower values indicate better performance. Acceptable values vary based on industry and application.

- Insertion Loss (IL): This measures the optical signal loss as it passes through a fiber optic component. Lower values are preferable. Acceptable values vary based on industry and application.

- Return Loss (RL): This quantifies the amount of light reflected back towards the source. Higher values indicate less reflection and a more efficient system.

- Polarity: This ensures the correct alignment of transmit and receive paths within the MPO system to prevent miscommunication.

| Insertion Loss Category | Value |

|---|---|

| Standard Loss | ≤0.5dB |

| Low Loss | ≤0.35dB |

| Ultra-low Loss | ≤0.25dB |

Return Loss Measurement for MPO Trunk Signal Integrity

Return Loss (RL) measures the amount of light reflected back towards the source. Higher RL values indicate less reflection and a more efficient system. This is critical for maintaining signal integrity, especially in high-speed networks.

Optical Power Measurement for MPO Trunk Health

Optical power measurement verifies the signal strength at various points in the network. This confirms the MPO trunk link delivers adequate power for connected devices. It helps diagnose issues like excessive attenuation.

Advanced Testing for MPO Trunk Assemblies

Beyond basic measurements, advanced testing provides deeper insights into MPO assembly quality.

End-Face Inspection with Fiber Optic Microscopes for MPO Trunk Quality

End-face inspection uses fiber optic microscopes. This visual check identifies scratches, dust, or other contaminants on connector end-faces. Clean end-faces are vital for optimal optical performance.

Optical Time Domain Reflectometry (OTDR) for MPO Trunk Fault Location

Optical Time Domain Reflectometry (OTDR) locates faults within the fiber optic cable. It identifies breaks, splices, and connectors. OTDR provides a graphical trace of the fiber link.

Interferometer Testing for MPO Trunk Connector Geometry

Interferometer testing measures the physical geometry of connector end-faces. This includes parameters like radius of curvature and fiber height. Precise geometry ensures optimal physical contact and low insertion loss.

Documentation and Certification for MPO Trunk Deployments

Comprehensive documentation and certification are essential for managing the fiber infrastructure.

Maintaining Comprehensive Test Records for MPO Trunk Infrastructure

Maintaining detailed test records is crucial. These records provide a baseline for future troubleshooting and performance monitoring. They document the health of the MPO trunk infrastructure.

Compliance with Industry Standards for MPO Trunk Certification

Compliance with industry standards ensures interoperability and performance. Certification confirms the deployment meets established benchmarks.

- Quality Assurance Certifications: ROHS, CE, OMC ISO, AS9100D, ITAR.

- Product Compliance: NEC 770 (for plenum-rated assemblies).

- Testing Standards: EIA-455-171, NECA-FOA-301, IEC 61280-4-5.

- Inspection Standards: IEC 61300-3-35 (end-face), IEC 61755-3-31 (geometry).

- Connector Specifications: IEC 61754-7, EIA/TIA-604-5 (FOCIS 5).

Generating Professional Test Reports for MPO Trunk Installations

Professional test reports summarize all testing results. These reports serve as official documentation of the installation’s quality and compliance. They are valuable for audits and future reference.

6. Optimizing MPO Trunk Infrastructure for Future Scalability

Data centers must plan for future growth. Optimizing MPO trunk infrastructure ensures scalability. This prepares networks for increasing demands.

Planning for Higher Speeds and Bandwidth with MPO Trunk Upgrades

Data centers constantly upgrade to faster speeds. MPO trunk solutions facilitate these transitions.

Migrating from 10G to 40G/100G/400G with MPO Trunk Solutions

Migrating to higher speeds requires careful planning. For 400G and beyond, 16-fiber connectivity is the most efficient building block. It supports maximum switch capacity. This allows for future upgrades to 800G and 1.6T. Legacy 8-fiber deployments can upgrade to 16-fiber. This involves doubling the fiber count at the front of the panel. SN connectors can save space. When moving from 12- or 24-fiber trunks to 8- or 16-fiber setups, consider business needs. While 8-fiber is an option, 16-fiber offers better port density for 16-fiber applications. To transition from legacy 12- and 24-fiber deployments without full replacement, use adapters and array cables. For example, LCs on a patch panel can connect to 8-fiber MPOs. Or, break out 24-fiber trunks into 8- or 16-fiber arrays. Prioritize infrastructure solutions that support both older 12- and 24-fiber designs and newer 8- and 16-fiber configurations. This avoids time-consuming panel modifications. Optical components must provide high bandwidth and low loss for 40G, 100G, and 400G. These higher speeds should be part of day-one design requirements. This prevents cabling infrastructure redesigns. Modular patch panels offer a scalable alternative to custom breakout cables. They integrate equipment of different network speeds. This provides a cost-effective way to future-proof the network.

Future-Proofing MPO Trunk Deployments with Higher Fiber Counts

Higher fiber counts ensure future compatibility. Data centers can support new technologies. This avoids costly re-cabling projects.

Considerations for Emerging Data Rates and MPO Trunk Compatibility

New data rates emerge regularly. MPO trunk compatibility is key. Ensure chosen solutions can adapt to future standards.

Modular Design Principles for MPO Trunk Systems

Modular designs offer flexibility. They simplify network management.

Utilizing MPO Cassettes and Panels for Flexible MPO Trunk Connectivity

MPO cassettes and panels provide flexible connectivity. They eliminate field splicing variability. This cuts installation time by up to 75%. It also improves consistency. They facilitate tool-free network reconfigurations. This uses a push-pull mechanism. They support incremental capacity expansion. This allows activating additional fiber pairs as bandwidth needs grow. It avoids complete infrastructure replacement. They maintain backward compatibility with legacy 10G equipment. They also enable 40G/100G capacity. This allows incremental capacity activation. A regional cloud services provider upgraded from 100G to 400G without service interruption using this method.

Ease of Adds, Moves, and Changes with Modular MPO Trunk Components

Modular components simplify network changes. They reduce downtime. They support rapid scaling due to plug-and-play capability. Technicians can quickly connect or reconfigure panels. They do not need specialized fiber optic skills.

Scalable MPO Trunk Architectures for Growing Data Center Needs

Scalable architectures meet growing demands. They reduce cable clutter in multi-floor or multi-building installations. They speed up network rollouts. They allow swapping or upgrading modules without disturbing other links. This slashes cable count by up to 80% in hyperscale data centers. It frees space for airflow. It simplifies moves, adds, and changes in data centers.

Density and Space Utilization with MPO Trunk Cables

High-density solutions maximize space. They improve airflow.

Maximizing Rack Space Efficiency with High-Density MPO Trunk Solutions

High-density MPO trunk solutions maximize rack space. MTP/MPO systems consolidate 8 to 72 individual fibers into a single connector. This significantly increases fiber density. It reduces cable footprint. Structured cabling with MTP/MPO trunk systems forms permanent backbone links. They transition to individual duplex connections at patch panels. This uses cassettes or hybrid cords. This separates high-density aggregation from flexible patching zones. It reduces pathway congestion by over 50%. Pre-terminated trunk assemblies reduce installation time by 80%. They ensure consistent polarity and performance. Breakout cables feature MTP/MPO on one end. They have multiple lower-density connectors on the other. This facilitates speed transitions. For example, MTP-12 to 6x LC Duplex for 40G/100G to 10G/25G. MTP-16 to 8x LC Duplex for 400G to 100G. They simplify topology by eliminating intermediate patch panels for speed conversion. A regional financial services provider reduced their cabling infrastructure from five 42U racks to 1.5 racks. This was a 70% space recovery. They achieved this by migrating to MTP/MPO-12 trunk cables with LC cassettes. This happened during a 10G to 100G network upgrade. Pre-terminated trunk assemblies allowed installation in 3 days. This was instead of a projected 2 weeks. This also resulted in a 40% reduction in total cabling expenditure. Recovered rack space was redeployed for additional compute infrastructure. This generated an estimated $180,000 annual revenue.

Reducing Cable Congestion and Improving Airflow with MPO Trunk Assemblies

MPO trunk assemblies reduce congestion. They improve airflow. This prevents performance fluctuations.

Vertical and Horizontal Cable Management for MPO Trunk Optimization

Proper cable management is essential. It prevents airflow blockage and overheating. It simplifies moves, adds, and changes. Use high-capacity cable managers and overhead pathways.

7. Establishing Robust MPO Trunk Maintenance Protocols

Data centers require robust maintenance protocols. These protocols ensure the long-term reliability and performance of MPO trunk infrastructure. Proactive measures prevent costly downtime.

Regular Inspection and Cleaning of MPO Trunk Connections

Regular maintenance routines are critical. They preserve the integrity of fiber optic connections.

Scheduled Connector Cleaning for MPO Trunk Reliability

Scheduled cleaning of MPO connectors is paramount. Contamination remains a leading cause of signal degradation. Technicians must adhere to a strict cleaning schedule. This prevents dust and debris buildup. Clean connectors ensure optimal light transmission and network reliability.

Environmental Monitoring for MPO Trunk Operating Conditions

Monitoring environmental factors is essential. These factors directly impact MPO trunk longevity. Data center operators should track:

- Temperature

- Humidity

- Exposure to chemicals

Maintaining stable conditions prevents material degradation and performance fluctuations.

Visual Inspection of MPO Trunk Cables and Components

Visual inspections identify potential issues early. Technicians should regularly check cables for physical damage. They also inspect connectors for wear or misalignment. Early detection prevents minor problems from escalating.

Proactive Troubleshooting for MPO Trunk Issues

Proactive troubleshooting minimizes network disruptions. It identifies and resolves problems before they affect operations.

Identifying Potential MPO Trunk Problems Early Through Monitoring

Early identification of issues is key. Network monitoring tools provide continuous oversight. They alert technicians to performance anomalies. This allows for timely intervention.

Utilizing Network Monitoring Tools for MPO Trunk Performance Alerts

Various tools aid in proactive troubleshooting.

- Visual Fault Locators (VFLs): These tools locate faults by emitting a visible red laser. The beam becomes visible at breaks or major bends. VFLs also check for continuity and polarity in MPO/MTP applications.

- Optical Time Domain Reflectometers (OTDRs): OTDRs provide a comprehensive link trace. They show the precise location of loss and reflectance events. This is useful for long links or when the cable is not visible.

- Fluke Networks MultiFiber Pro Optical Power Meter: This meter isolates issues within MPO cassettes. It tests MPO fiber trunks without fan-out cords. It simplifies polarity complexity. This tool measures power loss and validates polarity on 12 fibers in a single connector. It reduces test time significantly.

- EXFO’s ConnectorMax MPO Link Test Solution: This automated solution validates polarity, continuity, and connector cleanliness. It provides clear pass/fail status and reporting via a mobile app.

Testing ‘pre-tested’ cables after installation is also crucial. Shipping, storage, and handling can introduce contamination or damage.

Developing a Rapid Response Plan for MPO Trunk Outages

A rapid response plan is vital. It outlines steps for addressing MPO trunk outages quickly. This minimizes downtime and restores service efficiently.

Inventory and Lifecycle Management for MPO Trunk Assets

Effective asset management supports long-term network health.

Tracking MPO Trunk Component Lifespan and Warranty Information

Tracking component lifespan and warranty information is important. This helps predict when parts might fail. It also ensures replacements are covered.

Planning for Upgrades and Replacements of MPO Trunk Infrastructure

Strategic planning for upgrades and replacements is necessary. Data centers evolve. Infrastructure must keep pace with technological advancements.

Maintaining a Comprehensive Inventory of MPO Trunk Cables and Accessories

A comprehensive inventory simplifies maintenance. It ensures necessary components are readily available. This reduces delays during repairs or expansions.

Optimized MPO trunk connectivity profoundly transforms data center performance and efficiency. Adhering to the seven critical tips ensures peak performance and reliability for MPO trunk assemblies. A well-planned, meticulously implemented, and diligently maintained MPO trunk infrastructure provides significant long-term strategic advantages. This approach creates future-ready data centers.

FAQ

What distinguishes MPO from MTP connectors?

MTP connectors offer superior performance. They feature metal pin clamps and a floating ferrule. This minimizes breakage and improves alignment. Standard MPO connectors typically use plastic clamps and immobile ferrules. MTP connectors also include a removable housing for easier maintenance.

Why is MPO trunk polarity management crucial?

MPO trunk polarity management ensures correct signal flow. It aligns transmit and receive paths. Incorrect polarity leads to communication failures. Proper management prevents costly downtime and ensures seamless data transmission.

What are the primary MPO polarity methods?

The TIA 568 standard defines three main methods: Type A (straight-through), Type B (cross-over), and Type C (pair-flipped). Each method uses specific trunk cables and patch cables. They ensure correct fiber circuit polarity for different applications.

What advantages do pre-terminated MPO trunk cables offer?

Pre-terminated MPO cables significantly reduce installation time. They arrive factory-tested and polished. This ensures higher quality and consistent performance. They also minimize on-site labor costs and reduce the risk of installation errors.

Why is regular cleaning of MPO connectors essential?

Contamination is a leading cause of signal degradation. Dust and debris on MPO connector end-faces can block light transmission. Regular cleaning maintains optimal optical performance. It ensures network reliability and prevents costly signal loss.

How do data centers ensure MPO trunk scalability?

Data centers use modular designs and higher fiber counts. MPO cassettes and panels offer flexible connectivity. They support incremental capacity expansion. This allows for future upgrades to higher speeds like 400G and beyond without full infrastructure replacement.

What are the key testing parameters for MPO trunk performance?

Essential testing parameters include Insertion Loss (IL), Return Loss (RL), and optical power measurement. IL quantifies signal loss. RL measures reflected light. Optical power verifies signal strength. These tests confirm link integrity and performance.

What are the different MPO cable jacket ratings?

Cable jacket ratings include Plenum, Riser, and LSZH. Plenum-rated cables are for air-handling spaces. Riser-rated cables suit vertical runs. LSZH (Low Smoke Zero Halogen) cables produce minimal smoke and no toxic gases when burned. Each rating ensures safety in specific environments.