IP67 rated MPO panels are crucial for North Sea offshore wind farms. They provide robust, waterproof, and dust-tight fiber optic connectivity. This ensures reliable data transmission in extreme marine environments. These panels guarantee operational continuity and data integrity amidst the harsh North Sea conditions. An MPO Trunk Cable OM1 often connects to these systems. Such an MPO trunk setup is vital for the network’s backbone.

Key Takeaways

- IP67 MPO panels protect fiber optic connections in harsh North Sea wind farms.

- The North Sea has extreme weather, saltwater, and vibrations that damage equipment.

- IP67 means panels are fully dust-proof and can be submerged in water.

- MPO panels connect many fibers in a small space for fast data.

- These panels make wind farms more reliable and reduce costly downtime.

- They help send data clearly for monitoring and control of turbines.

- IP67 MPO panels are easy to install and can grow with new technology.

- They improve safety and meet important industry rules for offshore wind farms.

The Harsh Reality of the North Sea Environment

Offshore wind farms in the North Sea face relentless environmental challenges. These conditions demand exceptionally robust infrastructure. Understanding these harsh realities highlights the need for specialized equipment like IP67 rated MPO panels.

Extreme Weather Conditions

The North Sea is infamous for its severe and unpredictable weather patterns. These conditions directly impact the operational integrity of wind farm components.

High Winds and Storms

High winds and frequent storms are a constant threat. They exert immense pressure on structures and equipment. During the period from December 2022 to February 2023, waves exceeding 1.5 meters restricted operations 76% of the time. Waves over 2.5 meters made operations risky 39% of the time. An extreme event in mid-January 2023 recorded waves up to 7 meters. These powerful forces test the limits of all installed systems.

Heavy Rainfall and Sea Spray

Heavy rainfall and constant sea spray introduce significant moisture. This moisture penetrates unprotected components. It leads to short circuits and corrosion. The salt content in sea spray accelerates material degradation.

Freezing Temperatures and Ice Formation

Winter months bring freezing temperatures. Ice formation on turbines and platforms creates additional weight and stress. Ice can also damage sensitive connections and obstruct moving parts. Equipment must withstand these extreme cold conditions without failure.

Saltwater Corrosion and Humidity

Saltwater presents a highly corrosive environment. It poses a continuous threat to all metallic and electronic components.

Corrosive Effects on Metals

Offshore structures in the North Sea are exposed to aggressive corrosion agents. These harsh subsea environments necessitate robust protection. Nitrate-reducing microorganisms (NRMs) produce corrosive nitrite and elemental sulfur. Sulfate-reducing microorganisms (SRMs) utilize sulfate, producing sulfide and iron sulfides. Other microorganisms, including acetogens, iron-reducers, and methanogens, also contribute to microbiologically influenced corrosion (MIC). These biological and chemical agents relentlessly attack metal surfaces.

Impact on Electronic Components

Saltwater and corrosive agents severely impact electronic components. They degrade circuit boards and connection points. This leads to signal loss and system failures. Protecting these delicate parts is critical for data integrity.

High Humidity Challenges

High humidity levels persist even without direct water contact. This constant moisture promotes condensation. Condensation inside enclosures can lead to internal corrosion and electrical malfunctions. Effective sealing solutions are essential to combat this pervasive issue.

Vibration and Mechanical Stress

Offshore wind farms experience continuous mechanical stress. This stress comes from natural forces and operational activities.

Wave Action and Platform Movement

Ocean waves constantly buffet wind turbine foundations and platforms. This wave action causes continuous movement and vibration. Equipment must endure these dynamic forces without loosening or breaking.

Turbine Operation Vibrations

Wind turbines generate significant vibrations during operation. The rotating blades and machinery create constant mechanical stress. These vibrations can loosen connections and damage sensitive fiber optic cables over time.

Structural Fatigue on Equipment

The combination of extreme weather, corrosive elements, and constant vibration leads to structural fatigue. This fatigue weakens materials and components. It reduces their lifespan and increases the risk of failure. Equipment must withstand these cumulative stresses for decades of operation.

Understanding IP67 Rating and MPO Technology

Offshore wind farms require specialized technology. This technology must withstand harsh conditions. Understanding IP67 rating and MPO technology explains their importance.

What is IP67 Rating?

The IP (Ingress Protection) rating system classifies protection levels. It indicates how well an enclosure protects against solids and liquids. This standard uses two digits.

Ingress Protection Standard Explained

The first digit represents protection against solid objects. The second digit represents protection against liquids. Higher numbers indicate better protection.

Significance of ‘6’ for Dust Protection

The ‘6’ in IP67 signifies complete dust protection. It means no dust can enter the enclosure. This ensures internal components remain clean and functional.

Significance of ‘7’ for Water Immersion

The ‘7’ in IP67 indicates protection against water immersion. Equipment with this rating can withstand temporary submersion. This is crucial for marine environments.

| Protection Type | Condition/Criteria |

|---|---|

| Dust Ingress | 100% protected against solid objects like dust and sand; total dust ingress protection. |

| Water Ingress | Tested to function for at least 30 minutes while submerged in still water between 15 cm and 1 m in depth. |

This table shows the specific test conditions for IP67.

What are MPO Panels?

MPO stands for Multi-fiber Push On. MPO panels use these connectors. They house multiple optical fibers in a single ferrule.

Multi-fiber Push On Connector Overview

MPO connectors allow for quick and easy connection of many fibers. They simplify fiber optic cabling. This reduces installation time and complexity.

High-Density Fiber Optic Connectivity

MPO panels offer high-density fiber optic connectivity. They consolidate numerous fiber connections into a small space. This is essential for modern, high-bandwidth networks.

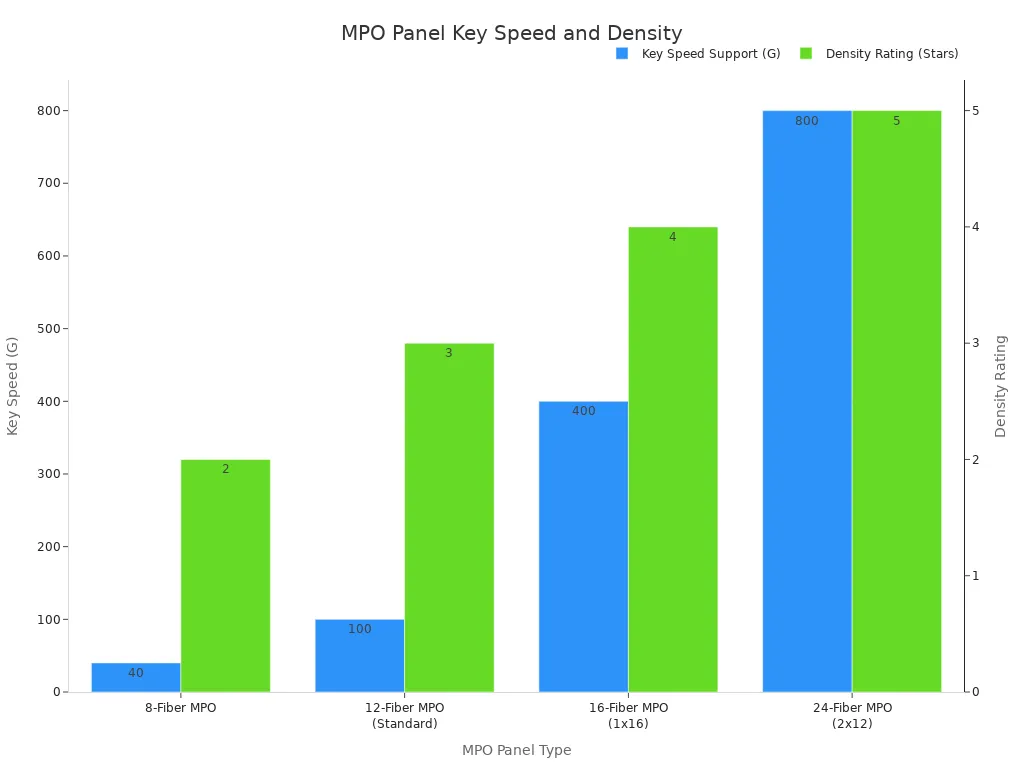

MPO connectors support very high data rates. For example, a 24-Fiber MPO (2×12) supports 800G Ethernet deployments. It offers the highest commercially available fiber density per MPO connector. This MPO trunk setup is vital for high-bandwidth needs.

Advantages of MPO for Data Centers

MPO panels provide significant port density. They support 72 LC Ports (Duplex) in 1RU. They also support 144 LC Ports (Duplex) in 2RU. This increases port density and saves space. It reduces rack count by up to 75% compared to LGX configurations. This provides a long-term connectivity solution for various high-speed requirements.

Synergy: Why IP67 and MPO Together?

Combining IP67 protection with MPO technology creates a powerful solution. It offers robust physical protection. It also provides high bandwidth capabilities.

Combining Robust Protection with High Bandwidth

This combination ensures sensitive fiber optic connections remain safe. It also supports the high data rates needed for modern applications.

Ideal Solution for Extreme Environments

This synergy is ideal for extreme environments like the North Sea. It protects against dust, water, and corrosion. It ensures reliable data flow in harsh conditions.

Ensuring Data Integrity and Physical Security

This combined approach ensures data integrity. It also provides physical security for critical network infrastructure. An IP67 rated MPO trunk system maintains reliable communication links.

Key Benefits of IP67 Rated MPO Panels in the North Sea

IP67 rated MPO panels offer significant advantages for offshore wind farms. These benefits directly address the unique challenges of the North Sea environment. They ensure operational efficiency and long-term viability.

Unmatched Reliability and Uptime

Reliability is paramount for offshore energy production. IP67 rated MPO panels deliver consistent performance. They withstand the harshest conditions.

Continuous Operation in Adverse Conditions

These panels guarantee continuous operation. They protect critical fiber optic connections from environmental threats. Wind farms maintain data flow even during severe storms or heavy sea spray. This resilience ensures the constant monitoring and control of turbines. Operators can manage the wind farm effectively without interruption.

Minimizing Costly Downtime

Connectivity failures lead to significant financial losses. Cable damage is a primary concern in offshore wind. It accounts for 53% of claims by value in Germany and Central Eastern Europe from 2014 to 2020. This compares to 20% for turbine failure. These incidents cause multi-million-dollar losses. They can disable an entire network of turbines.

Subsea transmission lines are particularly vulnerable. Outages are severe and lengthy. For example, the Block Island Wind Farm’s offshore cable needed at least six months for repairs. Erosion caused this damage. The likelihood of major outages lasting at least one month increases by 10% annually. This means an 80% probability of a major outage by the eighth year of operation. Such outages are expensive to repair. They also require increased reserve generating capacity in power systems. This leads to higher consumer costs.

Output degradation over time also increases project costs. An average degradation of 2.5% per year can increase a project’s levelized cost by 22% over a 20-year Power Purchase Agreement. A 4.5% annual degradation rate can increase the levelized cost by 58%. This can lead to project abandonment.

Downtime carries substantial financial implications:

| Cost Type | Financial Implication |

|---|---|

| Revenue Losses (Downtime) | $5,000 to $10,000 per turbine per day |

| Major Component Replacements | Hundreds of thousands of dollars |

| Generator Repair Costs | $50,000 to $200,000 |

| Power Converter Replacement | $50,000 to $200,000 per event |

| Transformer Repair Costs | Can exceed $1 million, with weeks of downtime |

These panels help secure revenue streams:

- Feed-in Tariff (FiT): Downtime directly impacts revenue. Payments link to actual generation. Consistent energy output is critical for fixed payments per kWh generated.

- Production Tax Credit (PTC): Extended outages reduce overall profitability. They limit energy production, which forms the basis for these tax credits.

Preventing Environmental Damage to Connections

IP67 rated MPO panels actively prevent environmental damage. The ‘6’ rating ensures complete dust protection. No dust or sand can enter the enclosure. The ‘7’ rating protects against water immersion. This means connections remain dry and clean. Saltwater, humidity, and ice cannot compromise the fiber optics. This robust protection extends the life of the entire network.

Enhanced Data Transmission Integrity

Reliable data transmission is the backbone of modern wind farm operations. IP67 MPO panels safeguard this critical function.

Secure Connections for Critical Data

These panels provide secure connections for vital data. They protect against physical intrusion and environmental interference. This ensures that operational commands, sensor readings, and performance metrics transmit without corruption. Data integrity is crucial for safe and efficient wind farm management.

Preventing Signal Degradation

Environmental factors often cause signal degradation. Moisture, dust, and corrosion can weaken fiber optic signals. IP67 rated MPO panels seal connections effectively. They prevent these elements from reaching the delicate fiber ends. This maintains optimal signal strength and clarity. Operators receive accurate data consistently.

Supporting Real-time Monitoring and Control

Offshore wind farms rely on real-time data. This data enables immediate adjustments and proactive maintenance. IP67 MPO panels ensure the continuous flow of high-quality data. This supports sophisticated SCADA systems and remote control operations. Operators can respond quickly to changing conditions. This optimizes energy production and enhances safety.

Reduced Maintenance and Operational Costs

Investing in IP67 rated MPO panels leads to significant cost savings over time. Their robust design minimizes the need for frequent interventions.

Increased Durability and Longevity

These panels offer exceptional durability. They withstand constant exposure to harsh marine elements. Their robust construction resists corrosion, vibration, and extreme temperatures. This extended lifespan reduces the need for premature replacements. It ensures the infrastructure remains functional for decades.

Fewer Failures and Replacements

The superior protection of IP67 panels translates directly into fewer failures. Connections remain stable and protected. This reduces the incidence of component breakdowns. Wind farm operators experience less equipment malfunction. This also means fewer costly replacements of damaged parts.

Lower Labor Costs for Repairs

Fewer failures mean less need for repair crews. Offshore repairs are expensive. They require specialized personnel, vessels, and equipment. By minimizing failures, IP67 MPO panels significantly lower these labor costs. They reduce the frequency of maintenance trips to remote offshore locations. A reliable MPO trunk system contributes to overall operational efficiency.

Faster Deployment and Scalability

Offshore wind farm projects operate under tight schedules and challenging conditions. IP67 rated MPO panels significantly streamline the deployment process. They also offer excellent scalability for future growth.

Ease of Installation in Challenging Locations

Installing fiber optic networks offshore presents unique difficulties. Weather windows are often short. Working conditions can be hazardous. IP67 rated MPO panels simplify this process. They use pre-terminated MPO connectors. This eliminates the need for complex, time-consuming field splicing. Technicians can quickly plug and play connections. This reduces the time workers spend in harsh environments. MPO-based fiber optic networks can reduce installation time by up to 75% compared to traditional fiber systems. This speed is crucial for meeting project deadlines. It also minimizes exposure to risks for installation crews.

Efficient Network Expansion

Offshore wind farms often expand over time. New turbines or monitoring systems may require additional connectivity. IP67 MPO panels facilitate efficient network expansion. Their design allows for easy integration of new fiber runs. Operators can add capacity without disrupting existing infrastructure. This modularity supports seamless upgrades. It ensures the network can adapt to evolving technological demands. This capability future-proofs the wind farm’s communication backbone.

Modular Design Benefits

The modular design of IP67 MPO panels offers several advantages. Each panel acts as a self-contained unit. This simplifies inventory management. It also makes troubleshooting easier. If a module experiences an issue, technicians can quickly replace it. This reduces repair times. It also minimizes the need for specialized tools on site. A modular MPO trunk approach supports future growth. It provides flexibility for network reconfigurations. This design philosophy enhances overall system resilience.

Safety and Compliance

Safety is paramount in the offshore energy sector. Compliance with industry standards and regulations is non-negotiable. IP67 rated MPO panels contribute significantly to both.

Meeting Offshore Industry Standards

The offshore industry has stringent standards for equipment. These standards address environmental resistance, reliability, and performance. IP67 rated MPO panels meet these rigorous requirements. Their robust construction ensures they withstand extreme conditions. This compliance helps wind farm operators achieve necessary certifications. It also demonstrates a commitment to high-quality infrastructure.

Contributing to Operational Safety

Reliable communication systems are vital for operational safety. IP67 MPO panels ensure uninterrupted data flow. This supports critical safety systems. These systems include emergency shutdown controls and environmental monitoring. Secure and stable connections prevent communication failures. Such failures could lead to dangerous situations. The panels help maintain a safe working environment for personnel. They also protect valuable assets.

Regulatory Adherence

Offshore wind farms must adhere to numerous regulations. These regulations cover environmental protection, worker safety, and data security. Using IP67 rated MPO panels helps meet these regulatory obligations. Their sealed design prevents environmental contamination. Their robust performance ensures data integrity. This adherence avoids potential fines and legal issues. It also builds trust with regulatory bodies and stakeholders.

Applications and Implementation in Offshore Wind Farms

IP67 rated MPO panels find extensive application in offshore wind farms. They provide the critical connectivity needed for various operational aspects. These panels ensure reliable data flow across the entire infrastructure.

Inter-Turbine Communication with MPO Trunk Cables

IP67 rated MPO panels play a vital role in connecting individual wind turbines. They ensure seamless data flow across the entire wind farm. This robust connectivity is essential for efficient operation and management.

High-Speed Data Exchange Between Turbines

Wind turbines constantly generate large volumes of data. They need to exchange this information rapidly. This data includes operational status, power output, and diagnostic alerts. High-speed data exchange allows turbines to synchronize their operations. It helps optimize energy production. It also enables quick responses to changing wind conditions. MPO panels provide the necessary bandwidth for this critical communication.

Network Backbone for Wind Farm

MPO panels, combined with MPO trunk cables, form the primary communication backbone for offshore wind farms. These high-density fiber optic connections link each turbine to the next. They create a resilient and high-capacity network. This backbone supports all data traffic within the wind farm. It ensures reliable communication pathways for all systems.

SCADA System Integration

The Supervisory Control and Data Acquisition (SCADA) system relies heavily on this inter-turbine communication. SCADA systems collect real-time data from every turbine. They use this data to monitor performance, control operations, and detect faults. IP67 MPO panels ensure the SCADA system receives accurate and timely information. This integration allows operators to manage the entire wind farm from a central location. It optimizes efficiency and enhances safety.

Substation and Control Room Connectivity

IP67 rated MPO panels also bridge the gap between the wind farm and onshore control centers. They facilitate the crucial flow of aggregated data.

Linking Turbines to Offshore Substations

Individual turbines transmit their data to an offshore substation. This substation acts as a central hub. IP67 MPO panels connect the turbines to this substation. They ensure secure and high-bandwidth links. The substation then aggregates data from all connected turbines. It prepares this data for transmission to shore.

Connecting to Onshore Control Centers

From the offshore substation, aggregated data travels to onshore control centers. This long-distance transmission requires highly reliable fiber optic connections. IP67 MPO panels protect these critical links at the substation. They ensure data integrity during its journey. Onshore control centers then analyze this data. They use it for strategic decision-making and long-term planning.

Data Aggregation and Transmission

MPO panels are instrumental in the aggregation and transmission process. They handle the high volume of data coming from multiple sources. They consolidate these signals efficiently. This ensures smooth and rapid transmission to onshore facilities. The robust nature of IP67 panels guarantees uninterrupted data flow. This is vital for continuous monitoring and control of the entire wind farm.

Sensor and Monitoring Systems

Offshore wind farms deploy various sensors and monitoring systems. These systems provide crucial insights into environmental conditions and turbine health. IP67 MPO panels support their connectivity.

Supporting Environmental Sensors

Environmental sensors gather data on weather, ocean conditions, and wildlife. This information helps optimize turbine operation and ensure regulatory compliance. Fiber optic temperature sensors are one example. They provide precise temperature monitoring systems. These sensors rely on robust fiber optic connections. IP67 MPO panels protect these connections from harsh marine elements. This ensures accurate and continuous data collection.

| Sensor Type | Application |

|---|---|

| Fiber Optic Temperature Sensors | Temperature monitoring systems |

| Fiber Bragg Grating (FBG) Sensors | Blade strain and deformation monitoring |

Turbine Performance Monitoring

Monitoring turbine performance is essential for maximizing energy output and preventing failures. Fiber Bragg Grating (FBG) sensors are critical for this task. They monitor blade strain and deformation. These sensors provide real-time data on the structural integrity of turbine blades. IP67 MPO panels ensure these sensitive sensor connections remain operational. Advanced monitoring systems also leverage cutting-edge technologies:

- Edge computing technology improves on-site data processing.

- 5G communication technology enables higher-speed data transmission.

- Convergence of digital twin, artificial intelligence, and Internet of Things technologies provides advanced monitoring capabilities.

These technologies rely on robust and high-bandwidth fiber optic infrastructure.

Structural Health Monitoring

Offshore wind farm structures face constant stress from the environment. Structural health monitoring systems track the integrity of foundations, towers, and blades. Fiber optic sensors embedded within these structures detect subtle changes. They identify potential fatigue or damage early. IP67 MPO panels provide the secure and reliable connections for these monitoring systems. This proactive approach helps prevent catastrophic failures. It extends the operational life of the wind farm.

Future-Proofing Offshore Wind Farm Networks

Offshore wind farms represent significant, long-term investments. Therefore, their communication infrastructure must withstand current demands and adapt to future needs. IP67 rated MPO panels offer a robust solution. They ensure the network remains relevant and efficient for decades. This approach protects the initial investment and supports continuous innovation.

Adaptability to Evolving Technologies

Technology advances rapidly. Offshore wind farms must integrate new systems and sensors over their operational lifespan. IP67 MPO panels provide the necessary flexibility. Their modular design allows for easy upgrades. Operators can swap out components or add new fiber links without replacing the entire cabling system. This adaptability supports the integration of emerging technologies. These include advanced AI-driven analytics, sophisticated IoT devices, and next-generation sensor networks. The physical infrastructure remains agile. It accommodates future communication protocols and hardware. This ensures the wind farm’s network stays at the forefront of technological innovation.

Support for Increased Data Demands

Modern wind farms generate and consume vast amounts of data. This data volume will only increase. Detailed performance analytics, predictive maintenance algorithms, and enhanced environmental monitoring require substantial bandwidth. IP67 MPO panels are inherently designed for high-density fiber optic connectivity. They support multiple fibers within a single connector. This capability easily handles current and future data demands.

- High Bandwidth Capacity: MPO panels support data rates up to 400G and 800G Ethernet. This prevents network bottlenecks.

- Scalable Fiber Count: They accommodate a large number of fibers. This allows for significant data throughput.

- Future-Ready: The design anticipates the exponential growth of data. It ensures the network can scale without major overhauls.

This robust capacity ensures the wind farm’s network can process all critical information. It supports real-time decision-making and optimizes energy production.

Long-Term Infrastructure Investment

Investing in IP67 rated MPO panels represents a strategic long-term decision. Their superior durability and adaptability translate into significant cost savings over the wind farm’s operational life. The initial capital expenditure for high-quality, future-proof infrastructure pays dividends.

"A well-designed and robust communication infrastructure is not an expense; it is an investment that safeguards operational continuity and maximizes return on investment for offshore wind projects."

This investment avoids costly retrofits and system overhauls. The IP67 rating guarantees protection against the harsh North Sea environment. This extends the lifespan of the fiber optic connections. It reduces the total cost of ownership. Reliable infrastructure also enhances investor confidence. It demonstrates a commitment to operational excellence and sustainability. Ultimately, these panels protect the entire wind farm investment. They ensure its long-term viability and success in the renewable energy landscape.

IP67 rated MPO panels are indispensable for offshore wind farms in the North Sea. They ensure the longevity, reliability, and efficiency of these critical energy infrastructures. These panels safeguard vital data transmission, contributing significantly to sustainable energy production. Their robust design and high-bandwidth capabilities make them essential for the future of renewable energy in extreme marine environments.

FAQ

What does IP67 mean for offshore wind farms?

IP67 means the panels are completely dust-tight. They also withstand temporary water immersion. This protection is crucial for the harsh North Sea environment. It ensures fiber optic connections remain safe and functional.

Why are MPO panels suitable for offshore environments?

MPO panels offer high-density fiber optic connectivity. They consolidate many fibers into a small space. This design supports high bandwidth needs. When combined with IP67 rating, they provide robust, reliable data links in extreme conditions.

How do these panels improve data transmission?

IP67 MPO panels prevent environmental elements from reaching fiber connections. This protection stops signal degradation. It ensures secure and clear data flow. This supports real-time monitoring and control systems effectively.

Do IP67 MPO panels reduce maintenance costs?

Yes, they significantly reduce maintenance costs. Their durability and protection lead to fewer failures. This means less need for expensive offshore repairs. It also extends the lifespan of the network infrastructure.

Are these panels easy to install offshore?

Yes, they offer easier installation. MPO panels use pre-terminated connectors. This eliminates complex field splicing. Technicians can quickly plug and play connections. This reduces installation time and risks in challenging locations.

How do they contribute to wind farm safety?

They ensure reliable communication for critical safety systems. This includes emergency shutdown controls. Stable connections prevent communication failures. This helps maintain a safe working environment for personnel and protects assets.

Can they support future technology upgrades?

Yes, they are future-proof. Their modular design allows for easy upgrades. They support increased data demands. This adaptability ensures the network can integrate new technologies. It protects the long-term infrastructure investment.