Pre-terminated MPO/MTP Trunk Cables significantly accelerate data center and network deployments. These advanced cables eliminate complex on-site fiber termination processes. Organizations experience immediate, tangible time savings in infrastructure setup. Pre-terminated solutions consistently reduce installation time by 70-80% compared to traditional methods. Projects that once took weeks now complete in days, enabling efficient data center wiring. For example, using an MPO MTP Trunk cable OM2 can dramatically speed up deployment.

Key Takeaways

- Pre-terminated MPO/MTP cables install much faster than old cables.

- These cables come ready to use, like ‘plug-and-play’ devices.

- MPO/MTP connectors connect many fibers at once, saving time.

- Factory testing makes these cables very reliable and reduces mistakes.

- Using these cables saves money on labor and avoids costly re-work.

- MTP connectors are better MPO connectors, with improved performance.

- These cables help networks grow and support faster internet speeds.

- They are great for data centers and large computer networks.

Understanding Pre-terminated MPO/MTP Trunk Cables

What Are MPO/MTP Connectors?

Multi-Fiber Push-On Technology

MPO (Multi-fiber Push On) connectors represent a significant advancement in fiber optic technology. NTT Communications developed them in the 1980s to overcome the limitations of single-fiber connectors. These connectors offer higher port density. Their compact design allows for significantly more fibers, typically 12 in a single row, but also 24, 32, or 64 cores. This design drastically reduces the number of connectors, patch cords, and rack space needed. MPO connectors adhere to international standards, ensuring interoperability.

MPO connectors consist of multiple optical fibers, commonly 8 or 12, arranged in parallel. They feature precision-aligned optical cores and a rectangular metal shell. They dock multiple optical fibers in one connection, ensuring precise alignment and coupling for bidirectional transmission of multiple optical signals. MPO connectors typically have an insertion loss of 0.2 dB to 0.5 dB and a return loss of 45 dB to 60 dB. They offer durability for 300 to 500 connection/disconnection cycles.

High-Density Fiber Connectivity

MTP (Multi-fiber Termination Push-on) connectors are an enhanced, high-performance variant of MPO. US Conec holds the registered trademark for MTP. They maintain backward compatibility while improving optical and mechanical performance through redesigned components. MTP connectors generally offer better performance and reliability than MPO connectors due to design enhancements. Their floating ferrule design provides a larger margin of error, leading to reduced insertion loss and improved return loss characteristics. This makes them ideal for complex MPO fiber networks. MTP connectors feature highly accurate alignment pin tips that ensure consistent, strong connections, preventing signal deterioration. The detachable nature of MTP housing simplifies maintenance and polarity reversal, enhancing flexibility and reliability.

Both MPO and MTP connectors comply with international standards like IEC-61754-7 and TIA-604-5, allowing for interchangeability. MTP’s optimized design makes it preferred for mission-critical applications requiring high reliability and low insertion loss, such as 100G/400G backbone links. These connectors are crucial for modern data centers due to their space efficiency, scalability, and installation efficiency.

| Feature | MPO Connector | MTP Connector |

|---|---|---|

| Outer Frame Sleeve | Fixed, non-removable design | Removable sleeve for easy reprocessing |

| Ferrule Design | Fixed ferrule with limited alignment flexibility | Floating ferrule for improved docking performance |

| Push Ring Retention | Basic plastic retention, prone to accidental breakage | Metal pin clip for secure push ring fixation |

| Guide Pins (PINs) | Standard cylindrical plastic or metal pins | Oval-shaped metal pins for long-term performance |

| Insertion Loss | Typically 0.3–0.5 dB per connection | Low 0.1–0.3 dB per connection |

| Durability (Mating Cycles) | Up to 500 mating cycles | Up to 1,000 mating cycles |

Connectors are gendered to ensure proper mating. Male connectors have guide pins, while female connectors do not. A female connector always connects to a male connector. A mechanical feature called keying position ensures correct orientation during insertion and allows for referencing specific fibers. The key’s position determines the numbering of fibers within the connector.

The Pre-terminated Advantage

Factory-Assembled and Tested

Pre-terminated MPO/MTP cables are factory-assembled and tested. This manufacturing process occurs in controlled environments, often ISO-certified facilities. This ensures consistent connector quality and performance. Factory-terminated connectors generally exhibit lower insertion loss values compared to field-terminated connectors. For instance, a factory-terminated standard LCUPC connector typically has an insertion loss of around 0.3dB (Max). Field-terminated splice-on connectors can have significantly higher values, potentially 0.5dB or more, depending on technician skill and connector quality. This rigorous testing and quality control ensure high quality and performance of the optical link upon installation.

Plug-and-Play Design

The plug-and-play design of pre-terminated cables significantly reduces installation time. Installers can quickly and easily plug them in. This contrasts sharply with field termination and splicing, which take considerable time. Pre-terminated solutions are less prone to human error and typically have higher quality control, leading to more reliable connections. They are also less susceptible to damage during installation compared to field-terminated connectors, which can be affected by dust, moisture, and other environmental factors. MPO/MTP connectors are typically pre-terminated because they cannot be effectively terminated in the field using traditional mechanical splice or epoxy/polish connector methods. This makes pre-termination a practical necessity for these high-density connectors.

Key Trunk Cable Components

Fiber Count and Types

MTP/MPO trunk cables are available with fiber counts ranging from 8 to 144 fibers. Common MTP/MPO cable types are classified by their core counts: 8, 12, 24, and 16 cores. 8-fiber MTP/MPO cables offer lower cost and insertion loss for the same data rates as 12-fiber cables. 12-fiber MTP/MPO cables are widely used for 10G-40G and 40G-100G connections. 24-fiber MTP/MPO cables are typically used for connecting CFP-to-CFP transceivers and recommended for migration to 40/100/400GbE. 16-fiber MTP/MPO cables are designed for 400G short-reach cabling in Hyperscale data centers. They combine multiple 8-fiber parallel transceivers and interface with upcoming 16-fiber parallel fiber links like 400G QSFP-DD and OSFP.

Optical fibers are the primary components of MTP cables. They transmit data as light signals. They can be either single-mode, used for long-distance communication, or multi-mode, which has a larger core diameter and is best suited for shorter distances.

| Products | Wavelength | Max Transmission Distance | Application |

|---|---|---|---|

| OM3 | 850nm | 100m | Buildings, Campus |

| OM4 | 850nm | 150m | Buildings, Campus |

| OS2 | 1310nm/1550nm | 200km | Carrier Networks, MANs, & PONs |

Cable Jacket and Protection

The cable jacket is an outer layer made from robust materials like PVC or LSZH (Low Smoke Zero Halogen). It provides additional shielding for internal components and enhances fire safety by not producing toxic emissions when burned. MTP/MPO cable jackets are categorized by fire rating requirements, including LSZH, OFNP, and CMP. LSZH (Low Smoke Zero Halogen) MTP/MPO cables are free of halogenated materials. They protect personnel and equipment during fires, making them suitable for enclosed spaces. OFNP (Optical Fiber Nonconductive, Plenum) MTP/MPO cables lack electrically conductive elements and have the highest fire rating. This allows installation in ducts and other building airflow spaces. CMP (Communications Multipurpose Cable, Plenum) MTP/MPO cables are suitable for plenum spaces where air circulation for heating and air conditioning systems is facilitated.

How Pre-terminated Cables Reduce Installation Time

Pre-terminated MPO/MTP trunk cables fundamentally change the approach to network deployment. They significantly reduce installation time by eliminating complex, labor-intensive steps traditionally performed on-site. This shift from field-based work to factory-controlled processes streamlines the entire installation lifecycle.

Eliminating On-Site Termination

Traditional fiber optic installations demand meticulous, individual termination of each fiber strand. Pre-terminated solutions bypass these time-consuming steps entirely.

No Splicing or Polishing

Installers no longer need to perform individual cleaving, epoxy application, polishing, or inspection of each fiber. MTP/MPO systems arrive with pre-terminated and factory-tested assemblies, ready for immediate deployment. This multi-fiber push-on technology allows connecting numerous fibers simultaneously. It eliminates the need to terminate each individual fiber on-site, which speeds up installations and prevents common termination mistakes. This process removes the most time-consuming phases of traditional fiber deployment.

Reduced Tooling Needs

Eliminating on-site termination also drastically reduces the specialized tooling required. Technicians do not need expensive fusion splicers, cleavers, microscopes, or polishing kits. This simplifies the installer’s toolkit, lowers equipment costs, and reduces the logistical burden of transporting and maintaining complex machinery. The modular design of these systems also allows for easy reconfigurations and scalability, further enhancing efficiency during installations.

Faster Deployment and Connection

The design of pre-terminated MPO/MTP cables prioritizes speed and simplicity in deployment.

Simple Plug-and-Play

Pre-terminated connectors offer simple plug-and-play functionality. Installers deploy multi-fiber connections with a straightforward snap action, eliminating the need for careful alignment and threading. This ease of use dramatically accelerates the connection process. For a 24-fiber trunk, traditional methods require 2-4 hours to strip, cleave, polish, and test each fiber. In contrast, pre-terminated MTP cables allow for immediate deployment, often taking mere minutes. This efficiency translates to a 40% faster deployment for new equipment.

Rapid Rack-to-Rack Connectivity

Pre-terminated MPO/MTP cables excel at establishing rapid connections between racks, patch panels, and active network equipment. High-density connections mean fewer cables. For example, a 100G data center deployment requiring 288 fiber connections uses only 24 MTP trunk assemblies. This compares to 144 separate patch cords with traditional LC duplex cables. This reduction in cable count significantly reduces time spent on cable management, pathway congestion, and visual inspection. Teams report 30-50% reductions in overall deployment time when switching from field termination to pre-terminated MTP solutions for comparable scopes.

Streamlined Testing Procedures

Pre-terminated cables also simplify the testing phase, a critical component of any fiber optic installation.

Factory-Tested Assurance

MTP cable assemblies arrive factory-terminated and 100% tested. Manufacturers verify insertion loss, return loss, and end-face geometry in controlled environments. This rigorous factory testing shifts the testing burden from the job site to the factory floor. It ensures consistent quality and performance. Installers can trust the integrity of the cables upon arrival.

Simplified Field Verification

While factory testing provides comprehensive assurance, field verification remains necessary. However, pre-terminated cables simplify this process significantly. Installers only need to perform basic continuity and power meter tests. They do not need to conduct full Optical Time Domain Reflectometer (OTDR) testing for each individual fiber. This dramatically reduces the time spent on site for testing, allowing projects to move forward faster. For fiber maintenance, pre-terminated MTP solutions can reduce maintenance windows from 4.5 hours to just 45 minutes, representing a 10x improvement.

Beyond Speed: Cost and Efficiency Benefits

Pre-terminated MPO/MTP trunk cables offer more than just rapid deployment. They deliver substantial cost savings and efficiency gains throughout the entire network lifecycle. These benefits extend from initial installation to long-term maintenance and operational management.

Significant Labor Cost Reduction

The inherent design of pre-terminated cables directly translates into lower labor expenses for network deployments.

Fewer Man-Hours

Traditional fiber optic installations demand significant on-site labor. Technicians spend hours preparing, terminating, and testing individual fiber strands. Pre-terminated MPO/MTP cables eliminate most of these labor-intensive steps. They arrive ready for immediate connection. This drastically reduces the total man-hours required for installation. Projects complete faster, allowing teams to move on to other tasks sooner. This efficiency directly impacts project budgets.

Less Specialized Technicians

Field termination of fiber optics requires highly skilled and certified technicians. These specialists often command higher wages. Pre-terminated solutions, with their plug-and-play nature, simplify the installation process. Less specialized personnel can perform the physical installation of these cables. This reduces the reliance on expensive, expert labor. Companies can allocate their highly skilled technicians to more complex tasks, optimizing their workforce.

Minimizing Installation Errors

Factory assembly and rigorous testing significantly reduce the potential for human error during installation. This leads to more reliable networks from day one.

Consistent Factory Quality

Pre-terminated MPO/MTP cables undergo manufacturing in controlled factory environments. These facilities adhere to strict quality control standards. Each cable assembly receives thorough testing for performance parameters like insertion loss and return loss. This ensures consistent, high-quality connections.

Pre-Terminated Fiber Assemblies: Save time spent on field terminations by using pre-terminated fiber assemblies. These are already tested under controlled environment conditions making them faster and more reliable during deployments.

This controlled process minimizes the variability often seen with on-site terminations.

Lower Rework Risk

The consistent quality of factory-terminated cables directly translates to a lower risk of installation errors. Field termination introduces variables such as technician skill, environmental conditions, and equipment calibration. These factors can lead to faulty connections, requiring costly and time-consuming rework. Pre-terminated cables virtually eliminate these risks. They provide reliable connections from the start. This reduces the need for troubleshooting and re-installation, saving both time and money.

- Pre-terminated MTP cables significantly Reduce Installation Time and complexity. They allow for the connection of many optical fibers in a short period.

- They simplify the operation process and lower labor costs due to their plug-and-play nature.

- The use of MTP connectors drastically reduces the time required for fiber termination and testing compared to traditional methods.

- Subsequent maintenance and repair costs are also reduced, improving overall economic efficiency.

Accelerated Project Timelines

The speed and reliability of pre-terminated MPO/MTP cables directly contribute to faster project completion. This allows organizations to achieve their goals more quickly.

Faster Time to Service

Rapid deployment means networks become operational much faster. This is crucial for businesses needing to bring new services online or expand existing infrastructure quickly. Accelerated project timelines allow companies to realize revenue sooner or provide critical services without delay. The ability to deploy infrastructure rapidly provides a significant competitive advantage.

- Pre-terminated and factory-tested assemblies are ready for immediate deployment, significantly reducing installation times.

- Multi-fiber push-on technology allows simultaneous connection of numerous fibers. It eliminates the need for individual on-site termination and speeds up installations.

- This technology also reduces the chances of errors during termination.

- Modular design enables reconfigurations and scalability, further enhancing efficiency during installations.

Improved Resource Allocation

Faster project completion frees up valuable resources. Project managers can allocate their teams and equipment to other initiatives sooner. This optimizes resource utilization across the organization. It allows for more projects to run concurrently or for teams to focus on innovation rather than prolonged infrastructure deployments. This strategic advantage enhances overall operational efficiency.

Enhanced Performance and Reliability

Pre-terminated MPO/MTP trunk cables offer significant advantages beyond just speed and cost. They deliver superior optical performance and enhance overall network reliability. This leads to more stable and efficient data transmission.

Superior Optical Performance

The manufacturing process of pre-terminated cables ensures top-tier optical quality. This directly impacts network efficiency.

Precision Factory Polishing

Manufacturers produce pre-terminated MPO/MTP cables in controlled factory environments. They use advanced machinery for precision polishing of connector end-faces. This process achieves extremely smooth and flat surfaces. Such precision minimizes signal loss and reflection. It ensures optimal light transmission through the fiber core. Field polishing often cannot match this level of accuracy.

Lower Insertion Loss

Precision polishing directly contributes to lower insertion loss. Insertion loss measures the amount of signal power lost when light passes through a connector. Factory-terminated MPO/MTP connectors consistently achieve very low insertion loss values. This is crucial for high-speed networks. Lower loss means signals travel further and with greater integrity. This improves overall network performance and reduces the need for signal amplification.

Increased Network Uptime

Reliable connections and reduced troubleshooting are key benefits of pre-terminated solutions. They keep networks running smoothly.

Reliable Connections

Pre-terminated cables provide highly reliable connections. Their factory assembly eliminates common human errors associated with field termination. Each connection point is consistent and robust. This reduces the likelihood of intermittent signal loss or complete link failures. Networks experience fewer unexpected outages.

Reduced Troubleshooting

Pre-terminated MPO/MTP cables significantly enhance network uptime. They also reduce troubleshooting efforts. These cables eliminate guesswork and minimize installation errors. This happens because of factory-tested polarity configurations. This proactive approach prevents connectivity issues before they arise. It optimizes network performance. The use of pre-tested and factory-configured cables, along with polarity testers, drastically reduces the risk of extended downtimes. It also lowers operational costs. Incorrect polarity would otherwise require extensive testing and reconfiguration.

Scalability and Future-Proofing

MPO/MTP trunk cables are essential for building networks that can grow and adapt. They support future technological advancements.

Easy Upgrades and Expansions

Pre-terminated MPO/MTP cables simplify network upgrades and expansions. A single MTP/MPO connector can replace 12–24 LC/SC connectors. This leads to up to a 75% reduction in rack space. This is crucial for dense environments like hyperscale data centers. Their plug-and-play design enables rapid installation. This significantly reduces deployment time. For example, a 144-fiber backbone can deploy in minutes instead of hours with LC/SC. MPO trunk cables consolidate multiple fiber linkages into a minimal physical size. This simplifies network connections and builds rapid backbone infrastructure. This is essential for hyperscale data centers managing thousands of servers. They also facilitate high-density connections in limited data center spaces. This improves organization and maintenance.

Support for Higher Bandwidths

MPO/MTP cables are fundamental for supporting high-speed standards. These include 400G/800G Ethernet using parallel optics. They simplify upgrades without requiring rewiring. MPO trunk cables significantly boost bandwidth. They support 40G, 100G, and even 400G applications. They minimize signal loss for efficient data transmission. They are crucial for telecommunication providers deploying high-speed, low-latency connectivity for 5G and IoT. MPO trunk cables provide excellent scalability. They support 40G, 100G, 400GBASE-SR8, and even higher capacities. This allows networks to adapt to increasing data traffic and future equipment upgrades. A regional cloud provider, for instance, upgraded from 100G to 400G using these cables.

Practical Applications for Reduced Installation Time

Pre-terminated MPO/MTP trunk cables offer significant advantages across various networking environments. They streamline deployments and enhance efficiency in critical infrastructure. Organizations leverage these cables to reduce installation time and optimize network performance.

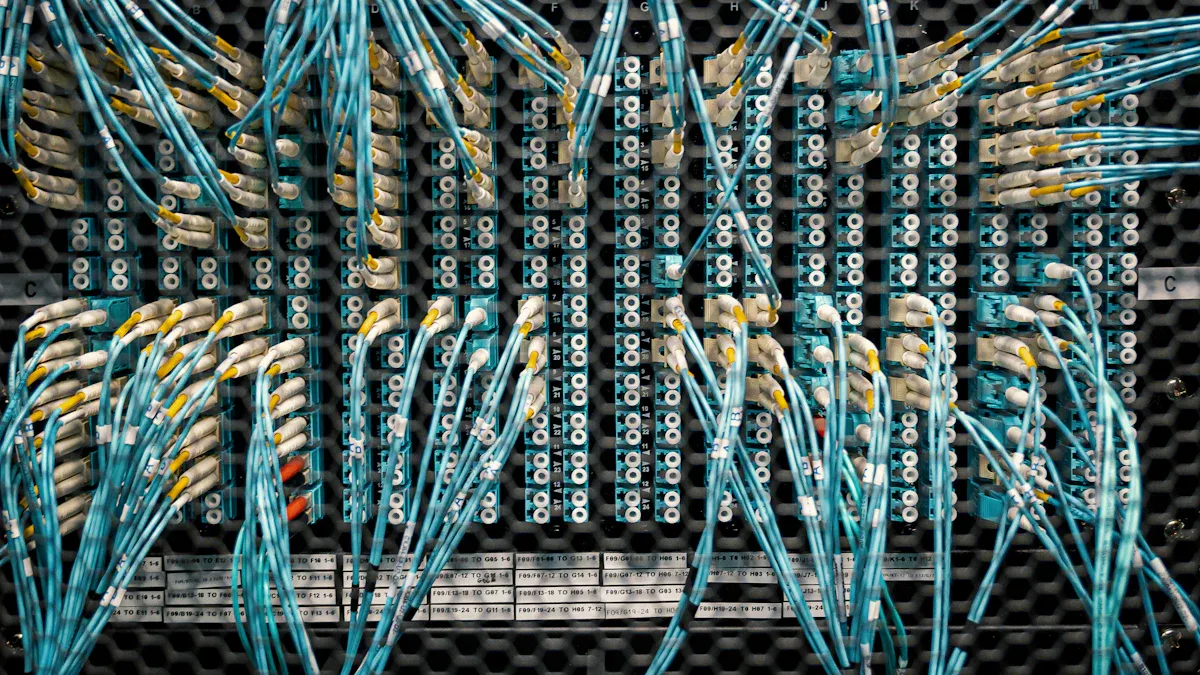

Data Center Interconnects

Data centers greatly benefit from the rapid deployment capabilities of MPO/MTP trunk cables. These cables are ideal for large-scale installations due to their scalability and ability to consolidate many fibers. They simplify cable management and support significant future expansion.

Spine-Leaf Architectures

MPO branch patch cables are particularly suitable for large-scale parallel interconnections within Spine-Leaf architectures. When terminated into MPO adapter panels on both ends, these trunks streamline centralized distribution and high-density cabling management. This makes them ideal for high-density deployments and scalable infrastructure. They provide high-speed, high-density connections between core switches and compute racks, ensuring rapid data transfer.

High-Density Patch Panels

MTP/MPO trunk cables are crucial for new data center build-outs and upgrading existing infrastructure. They replace older, lower-density cabling to boost backbone capacity and streamline pathways. This prepares the network for higher speeds. These cables are the preferred choice for 100G and 400G backbone connections. They offer superior optical performance and high density, such as 864 fibers in a 1U housing. This leads to infrastructure cost savings and frees up rack units.

Enterprise Network Backbones

Enterprise networks also utilize pre-terminated MPO/MTP cables for their backbone infrastructure. These solutions provide reliable and efficient connectivity across large organizational footprints.

Campus Area Networks

Pre-terminated fiber optic cabling systems are installed in enterprise data centers, colocation facilities, server farms, and telecommunication rooms. They serve as backbone networks, connecting LC ports to MPO on the rear of patch panels. This facilitates upgrades from 10G to 40/100G. Pre-terminated armored fiber patch cables are ideal for mission-critical data center backbones and other high-traffic areas within network backbones.

Building Risers

Riser-rated (OFNR) cables are specifically used in vertical settings. These cables run between floors through cable risers. Pre-terminated MPO/MTP trunk cables serve as highly reliable connections for higher floors and for runs between floors. Their robust design ensures consistent performance in these demanding environments.

Cloud and Hyperscale Deployments

Cloud and hyperscale data centers rely heavily on pre-terminated MPO/MTP trunk cables for their rapid expansion and high-bandwidth requirements.

Rapid Infrastructure Rollouts

Pre-terminated MPO/MTP Trunk Cables are widely adopted in large-scale data centers and enterprise networks. They facilitate rapid deployment, minimize installation errors, and enable seamless scalability. This makes them the preferred choice for organizations aiming to future-proof their network infrastructure. The ‘plug-and-play’ readiness of MPO solutions is highly valued due to high labor costs. This makes connector reliability paramount.

Modular Data Centers

The increasing demand for these cables is driven by the adoption of cloud computing, virtualization, and big data analytics. They are crucial for supporting high-bandwidth applications and reducing network downtime. Pre-terminated trunk cabling is a key use case for greenfield builds and modular data centers. MPO’s quick deployment profile offers a strategic advantage in environments where technician availability is limited and truck rolls are expensive.

Selecting the Right Pre-terminated MPO/MTP Trunk Cables

Choosing the correct pre-terminated MPO/MTP trunk cables is crucial for optimal network performance and efficient deployment. Careful consideration of specifications, customization, and quality ensures a robust and future-proof infrastructure.

Key Specifications to Consider

Understanding the core specifications helps match cables to specific network demands.

Fiber Type and Mode

Network designers must select the appropriate fiber type and mode. Single-mode (SM) fibers transmit data over long distances, suitable for campus backbones or inter-building connections. Multi-mode (MM) fibers, such as OM3, OM4, or OM5, serve shorter distances within data centers or enterprise networks. Matching the fiber type to the application prevents signal degradation and ensures efficient data transmission.

Connector Polarity and Gender

Connector polarity is a critical specification for pre-terminated MPO/MTP trunk cables. MPO systems require precise alignment between transmit (Tx) and receive (Rx) connections. Polarity mismatches occur when the chosen cable type does not align with equipment requirements or the overall cabling scheme. These mismatches can lead to communication failures. TIA-568 defines three polarity methods: Type A, Type B, and Type C. Incorrect polarity can result in signal loss, decreased data transmission rates, or increased error rates, especially in dense networks. For example, many 40G/100G QSFP transceivers typically use Type B breakout cables. Verifying the required polarity with the transceiver datasheet prevents network failures. Connectors also come in male (with guide pins) and female (without guide pins) genders, which must be correctly matched for proper mating.

Customization Options

Pre-terminated MPO/MTP trunk cables offer extensive customization, allowing for tailored solutions.

Cable Lengths and Breakouts

Pre-terminated MPO/MTP trunk cables offer comprehensive customization options. As dedicated fiber optics manufacturers, they can tailor fiber counts, cable lengths, and other specific requirements. This aligns with individual project demands, providing flexibility and versatility in meeting diverse connectivity needs. MTP/MPO breakout patch cables, also known as fan-out or harness patch cables, have MTP/MPO connectors on one end and simplex or duplex LC/SC/FC/ST connectors on the other. Common breakout options include MPO-LC, MPO-SC, MPO-ST, MPO-FC, and their MTP equivalents. MPO/MTP-LC breakout cables are popular, offering up to 144 fibers, with common versions being 8, 12, and 24 fibers. An 8-fiber cable typically uses 4 LC duplex connectors for SFP transceivers.

Jacket Ratings and Environmental Factors

Customization extends to fiber and boot length, and cable jacket types. These include PVC, LSZH, and OFNP. PVC (Riser/OFNR) jackets are common for general indoor use. LSZH (Low Smoke Zero Halogen) jackets are crucial for enclosed spaces, as they do not produce toxic fumes in a fire. Plenum (OFNP) jackets meet strict fire safety codes for use in air-handling spaces.

Importance of Quality and Standards

Adhering to quality standards ensures reliable and interoperable network infrastructure.

Adherence to Industry Standards

Pre-terminated MPO/MTP trunk cables should adhere to industry standards such as TIA/EIA-568 for proper polarity, network reliability, and ease of maintenance. This standard helps simplify deployment and troubleshooting in high-density fiber optic networks. These cables are 100% pre-tested to meet relevant cabling standards, ensuring quality assurance.

Reputable Manufacturers

Choosing reputable manufacturers guarantees high-quality products. These manufacturers follow strict production processes and conduct rigorous testing. They ensure their cables meet or exceed industry standards for performance and durability. This choice minimizes the risk of faulty components and ensures long-term network stability.

Pre-terminated MPO/MTP trunk cables fundamentally transform network infrastructure deployment. They deliver a powerful combination of speed, significant cost savings, and enhanced performance. Organizations achieve faster project completion and superior network reliability.

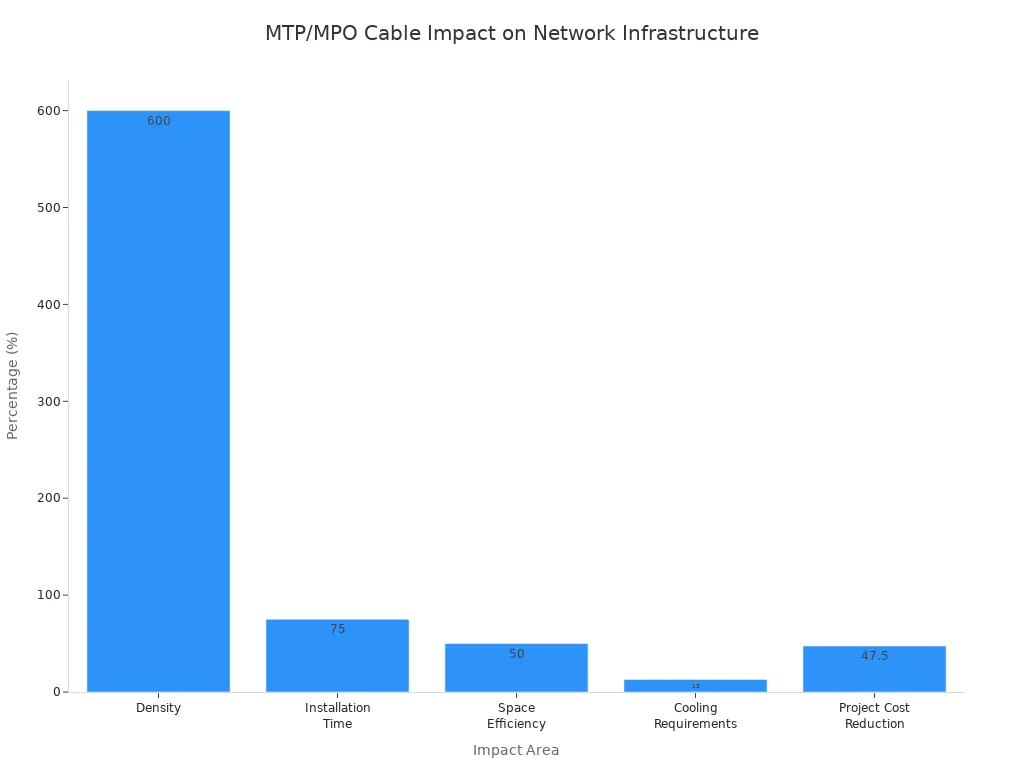

| Impact Area | MTP/MPO Trunk Cables | Traditional Cabling | Improvement/Savings |

|---|---|---|---|

| Density | 6x higher | Standard duplex | 6x improvement |

| Installation Time | 75% reduction | Standard | 75% reduction |

| Space Efficiency | 50% improvement | Standard | 50% improvement |

| Project Cost Reduction | 40-55% | Standard | 40-55% reduction |

These cables offer scalability and future-proofing, supporting bandwidth evolution from 10G to 400G and beyond. Adopting pre-terminated MPO/MTP solutions is essential for building modern, efficient, and high-performing network infrastructures.

FAQ

What is the main benefit of pre-terminated MPO/MTP cables?

They significantly reduce installation time. Factory assembly means technicians simply plug them in. This eliminates complex on-site termination, speeding up network deployment.

How do MPO and MTP connectors differ?

MTP connectors are an enhanced version of MPO connectors. They offer improved optical and mechanical performance. MTP features a floating ferrule and metal guide pins for better reliability and lower insertion loss.

Can less specialized technicians install these cables?

Yes, they can. The plug-and-play design simplifies installation. This reduces the need for highly specialized fiber optic technicians on-site. It also lowers labor costs.

What polarity types are available for MPO/MTP cables?

TIA-568 defines three main polarity methods: Type A, Type B, and Type C. Network designers must select the correct polarity to match their equipment and cabling scheme.

Are these cables suitable for future network upgrades?

Absolutely. MPO/MTP cables support higher bandwidths like 400G and 800G Ethernet. Their high-density design allows for easy upgrades and expansions, future-proofing network infrastructure.

Where are these cables commonly used?

They are widely used in data centers for spine-leaf architectures and high-density patch panels. Enterprise network backbones and cloud deployments also benefit from their rapid installation.

How do pre-terminated cables save money?

They reduce labor costs by minimizing man-hours and the need for specialized technicians. They also lower rework risks due to consistent factory quality. This accelerates project timelines and saves money.