PDUs deliver high-capacity, managed power distribution for demanding environments like data centers or industrial sites, while ordinary power strips extend basic, low-capacity power for home or office use. Choosing the right device ensures safety, reliability, and room for future growth.

Common safety incidents include:

- Power strips: Overloading, overheating, electrical fires, and electric shock, often from misuse or damaged wiring.

- PDUs: Arc flash risks in high-power setups, especially without proper training or safety protocols.

Key Takeaways

- PDUs provide high-capacity, safe, and managed power for demanding environments like data centers and industrial sites.

- Ordinary power strips offer simple, low-capacity power extension mainly for homes and offices with basic safety features.

- PDUs support advanced functions such as remote monitoring, load balancing, and environmental sensing to improve efficiency and prevent downtime.

- Power strips are easy to use but lack advanced safety and management features, making them unsuitable for critical or high-power setups.

- Choosing the right device depends on power needs, outlet compatibility, safety requirements, and future growth plans.

- PDUs come in various types, from basic to intelligent models, offering different levels of control and monitoring.

- Investing in PDUs may cost more upfront but reduces long-term risks, downtime, and maintenance expenses.

- Always prioritize safety certifications, proper installation, and avoid unsafe practices like daisy-chaining to ensure reliable power distribution.

PDU Overview

What Is a PDU?

A Power Distribution Unit (PDU) manages and distributes electric power to multiple devices in a structured and secure way. In high-density environments such as data centers, a PDU ensures reliable uptime for critical networking equipment. It extends beyond the capabilities of a basic power strip by offering surge protection, load balancing, and real-time energy monitoring. These features help maintain operational efficiency and prevent downtime. Modern PDUs play a vital role in supporting the infrastructure of server rooms and industrial facilities.

Key Features of PDUs

PDUs stand out due to their advanced technical specifications and robust construction. They support higher voltage and three-phase power, making them suitable for demanding applications. Most PDUs use industrial-grade materials like steel and include overload protectors, resettable fuses, and magnetic circuit breakers. The number of outlets ranges from 4 to 48, accommodating a wide variety of equipment. Many models offer network connectivity, enabling remote access and integration with management software. Additional features include notifications, threshold configuration, and environmental monitoring for temperature and humidity. These capabilities allow organizations to optimize energy use, reduce costs, and maintain safe operating conditions.

Tip: Rack-mounted PDUs, available in 1U, 2U, or 0U vertical form factors, save valuable rack space and support organized cable management in data centers.

| Feature | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Conductor Wire Gauge | Multiple gauge ratings, suitable for heavy-duty applications | Typically 14 AWG |

| Voltage Support | Supports higher voltage and three-phase power (208V/400V) | Usually single-phase only |

| Safety Features | Overload protectors, resettable fuses, magnetic circuit breakers | Often surge protectors only |

| Material and Build | Industrial-grade steel | Usually plastic |

| Mounting and Form Factor | Rack-mountable (vertical 0U, horizontal 1U/2U) | No specific mounting guidelines |

| Number of Outlets | 4 to 48 | 2 to 8 |

| Application Environment | Industrial, data centers, server rooms | Homes, offices |

Types of PDUs

PDUs come in several types, each designed for specific power management needs.

Basic PDU

A basic PDU provides standard power distribution without monitoring or advanced features. It suits small setups with predictable loads. Users often choose this type for cost-effective solutions where power needs remain stable.

Metered PDU

A metered PDU includes built-in energy meters that display real-time power consumption at the unit or outlet level. This feature helps prevent overloads and supports energy management. Facility managers use metered PDUs to plan capacity and optimize energy use.

Switched PDU

A switched PDU combines metering with remote switching capabilities. It allows users to control individual outlets remotely, enabling power cycling and sequencing. This type is valuable in environments with dynamic workloads or where remote troubleshooting is necessary.

Intelligent PDU

An intelligent PDU, sometimes called a managed PDU, offers the most advanced features. It provides detailed monitoring, alerting, and automation tools. Intelligent PDUs support remote management, outlet-level control, and integration with data center infrastructure management (DCIM) software. These units help organizations achieve maximum control, efficiency, and security in complex environments.

Ordinary Power Strip Overview

What Is an Ordinary Power Strip?

An ordinary power strip serves as a convenient solution for powering multiple devices from a single wall outlet. It consists of a block of electrical sockets attached to a flexible cable with a mains plug. Users often place power strips in areas where several devices cluster together, such as entertainment centers, home offices, or workshops. The design targets low-powered electronics like computers, monitors, printers, audio systems, and lamps. Power strips are intended for indoor use only and should not support high-power appliances like space heaters, refrigerators, or microwaves. Manufacturers do not recommend daisy-chaining power strips or connecting them to extension cords, as this increases the risk of overheating and electrical hazards. These devices are not suitable for permanent installation or use in hazardous or critical care environments.

Note: Power strips provide a temporary and flexible way to expand available outlets, but users must follow safety guidelines to prevent overloading and fire risks.

Key Features of Power Strips

Ordinary power strips offer a straightforward approach to power distribution. Most models include two to twenty outlets, allowing users to connect several devices at once. Some units feature surge protection, which helps shield sensitive electronics from voltage spikes caused by lightning or power surges. Others may include switches, indicator lights, or built-in fuses for added convenience and safety. The power cord length varies, with options ranging from less than one foot to over twenty-five feet, providing flexibility in placement.

| Feature | Ordinary Power Strips | Power Distribution Units (PDUs) |

|---|---|---|

| Power Capacity | Typically rated 15 to 20 amps | Support higher amperages with built-in circuit breakers |

| Power Cord Length | Varies from less than 1 foot to 25+ feet | Limited to 15 feet due to heavier load |

| Mounting Options | Mostly designed to lie on surfaces; some have mounting tabs | Designed for rack or cabinet mounting, horizontally or vertically |

| Surge Protection | Some provide surge protection | Generally do not provide surge protection; rely on separate surge arresters |

| Number and Type of Outlets | 2 to 20+ outlets, mostly standard NEMA 5-15R | 8 to 40+ outlets, variety of outlet types for IT equipment |

| Advanced Features | Usually none | Remote switching, metering, alerting, environmental monitoring |

Power strips do not offer advanced features like remote management or energy monitoring, which are common in PDUs. Their simple construction and ease of use make them ideal for non-critical environments.

Types of Power Strips

Basic Power Strip

A basic power strip provides multiple outlets without any surge protection or smart features. Users rely on these for temporary setups where additional sockets are needed, such as connecting lamps, chargers, or small electronics. The design remains simple, with a single switch or no switch at all.

Surge-Protected Power Strip

Surge-protected power strips include built-in components that absorb excess voltage during power surges. This feature protects sensitive devices like computers, televisions, and audio equipment from damage. Many surge-protected models display indicator lights to show active protection status. These strips are essential in areas prone to electrical storms or unstable power supply.

Smart Power Strip

Smart power strips introduce automation and energy-saving features. They may include Wi-Fi connectivity, allowing users to control outlets remotely through a smartphone app or voice assistant. Some models offer scheduling, energy monitoring, or automatic shutoff for idle devices. Smart power strips help reduce energy waste and provide greater convenience for modern homes and offices.

Tip: Always check for UL listing marks on power strips to ensure compliance with safety standards such as UL 1363. Avoid using power strips with high-power appliances or in damp environments to minimize risks.

PDU vs. Ordinary Power Strip: Direct Comparison

Functionality Differences

PDUs and ordinary power strips serve different roles in power distribution. A PDU manages and distributes electricity to multiple devices in environments that demand high reliability, such as data centers or industrial facilities. It supports higher voltages and offers advanced features like load balancing, remote monitoring, and outlet-level control. These capabilities help organizations maintain uptime and optimize energy use.

Ordinary power strips provide a simple way to extend the number of available outlets from a single wall socket. They target home and office environments where users need to power low-demand devices like computers, lamps, or chargers. Most power strips lack advanced management features. Some models include surge protection or basic switches, but they do not support remote access or detailed monitoring.

Tip: For critical infrastructure or high-density IT setups, a PDU delivers the control and reliability that ordinary power strips cannot match.

Safety and Protection Features

Safety remains a top priority when choosing between a PDU and an ordinary power strip. Each device type incorporates different safety mechanisms based on its intended environment and load capacity. The table below highlights key differences in safety and protection features:

| Feature Category | PDUs (Power Distribution Units) | Ordinary Power Strips (Japanese Standard Compliant) |

|---|---|---|

| Conductor Wire Gauge | Higher gauge wires (14 AWG to 6 AWG) for heavier load handling | Usually 14 AWG |

| Voltage Rating | Supports higher voltage three-phase (208V/400V) industrial use | Supports 110V/208V/230V single-phase for residential/commercial use |

| Surge Protection | Generally do not include surge protectors | Include built-in surge protectors (varistors) for lightning surge protection |

| Overload Protection | Include industrial-grade resettable fuses or magnetic circuit breakers (MCBs) | Usually lack overload protectors |

| Construction Material | Steel, designed for rack mounting with multiple outlets | Plastic body, fewer outlets |

| Safety Features | Overload protectors, MCBs | Dust-preventing shutters, child safety measures, insulation caps, centralized switches with indicator lamps, protective covered cords, varistors for surge protection |

PDUs use robust industrial-grade components, such as resettable fuses and magnetic circuit breakers, to handle higher loads and prevent overloads. Their steel construction and rack-mount design add durability and safety in demanding environments. In contrast, ordinary power strips focus on user-friendly features like surge protection, dust-preventing shutters, and child safety measures. These features suit residential and office settings, where the risk of high-load failure is lower.

Scalability and Expansion

Scalability defines how well a power distribution solution adapts to growing or changing needs. Ordinary power strips offer limited scalability. They lack remote monitoring, management, and advanced features, making them unsuitable for large-scale or mission-critical environments.

PDUs provide a range of options to support expansion and complex infrastructure:

- Basic PDUs function like high-capacity power strips but do not offer remote management, making them suitable for stable, budget-conscious setups.

- Metered PDUs display local real-time power metrics, helping users balance loads and plan capacity, though they may not connect to networks.

- Monitored PDUs enable remote access to power and environmental data, send alerts, and support proactive maintenance. These features make them ideal for large or critical environments.

- Switched PDUs allow remote control of individual outlets, enabling power cycling and remote shutdowns. This capability benefits multi-site or unmanned data centers.

- Advanced PDUs, such as ATS (Automatic Transfer Switch) and hot-swap models, provide automatic failover and servicing without downtime, supporting high-availability and scalable infrastructures.

PDUs handle higher voltages, offer more outlets, and include features like load balancing and circuit protection. These characteristics make them essential for scaling power distribution in large IT environments.

Monitoring and Control Capabilities

Advanced power distribution units offer significant advantages in monitoring and control compared to ordinary power strips. These units provide both remote and local monitoring, which helps organizations maintain reliable operations and respond quickly to issues.

- Network-grade power distribution allows users to monitor and manage power remotely through an RJ45 Ethernet port. Many models support integration with management consoles, such as the CyberPower Management Console, for centralized oversight.

- Local monitoring is available via digital LCD meters, which display real-time power usage and status directly on the unit.

- Upgradeable firmware and SNMP network interfaces enable enhanced control and future-proofing, allowing the system to adapt to evolving needs.

- Durable metal housing and flexible mounting options improve installation versatility and physical protection.

Ordinary power strips do not offer these capabilities. They provide only basic power distribution, with no monitoring or remote control features. Users cannot track energy consumption or control outlets from a distance. This limitation makes ordinary power strips less suitable for environments where uptime, efficiency, and proactive maintenance are critical.

Note: Advanced monitoring and control features in PDUs help prevent overloads, reduce downtime, and support efficient energy management in demanding environments.

Application Environments

The choice between a power distribution unit and an ordinary power strip depends largely on the application environment. The table below highlights the differences in preferred environments and technical specifications:

| Aspect | PDUs (Power Distribution Units) | Power Strips |

|---|---|---|

| Preferred Environments | Industrial and heavy-duty settings such as data centers, workplaces heavily dependent on electricity, outdoor/weather-proof use | Residential homes, regular offices, shops |

| Construction Material | Steel, suitable for rugged and industrial use | Plastic, designed for medium-duty appliances |

| Number of Outlets | 4 to 48 outlets, supporting multiple devices | 2 to 8 outlets |

| Conductor Wire Gauge | Supports 14 AWG to 6 AWG, allowing heavy-duty appliance use | Typically 14 AWG, suitable for medium-duty |

| Voltage Ratings | Supports 208V/400V three-phase power for industrial applications | Supports 110V/208V/230V single-phase power |

| Safety Features | Industrial-grade overload protection with resettable fuses or magnetic circuit breakers (MCBs) | Often includes surge protectors but lacks industrial-grade overload protection |

| Equipment Compatibility | Suitable for rack-mount IT servers, network switches, LCD drawers | Suitable for home entertainment, kitchen appliances, lighting, desktop computers |

| Power Stability & Safety | Stabilizes power supply and minimizes electrical accidents | Basic surge protection, less robust safety |

PDUs excel in environments that demand high reliability, such as data centers, industrial facilities, and workplaces with critical electrical loads. Their robust construction and advanced safety features make them ideal for these settings. Ordinary power strips fit best in homes, offices, and retail shops, where the power demands are lower and the risk of overload is minimal.

Cost and Value Considerations

When evaluating cost and value, organizations must look beyond the initial purchase price. Ordinary power strips and basic PDUs have lower upfront costs, but they often lack essential safety features such as surge protection, circuit breakers, and durable construction. This absence can increase the risk of equipment damage, leading to more frequent replacements or repairs and raising long-term costs.

Advanced PDUs require a higher initial investment. However, they include safety certifications, robust materials, and features like remote monitoring and energy efficiency. These attributes reduce downtime and maintenance needs. Investing in trusted brands with warranties further enhances long-term value by protecting against unexpected failures and repair expenses.

Basic PDUs and ordinary power strips may seem cost-effective at first. However, their lack of advanced features such as remote monitoring, energy efficiency, and power management can result in higher operational and maintenance expenses over time. Advanced PDUs—such as metered, monitored, and switched models—offer real-time power usage data, remote control, reduced downtime, and longer lifespan. These benefits contribute to better long-term value and lower maintenance costs. Organizations that prioritize reliability and safety often find that the total cost of ownership for advanced PDUs is lower over time, despite the higher initial price.

Comparison Table

When evaluating power distribution solutions, a clear side-by-side comparison helps decision-makers understand the strengths and limitations of each option. The table below outlines the most significant differences between PDUs and ordinary power strips across technical, safety, and functional categories.

| Feature Category | PDUs (Power Distribution Units) | Ordinary Power Strips |

|---|---|---|

| Gauge Ratings | Multiple conductor wire gauges from 14 AWG to 6 AWG, suitable for heavy-duty and industrial use | Typically 14 AWG, suitable for medium-duty appliances |

| Voltage Ratings | Support single-phase (110V/208V/230V) and three-phase (208V/400V) industrial voltages | Support single-phase voltages (110V/208V/230V) only |

| Outlet Types | Industrial-grade outlets (IEC C13/C19), plus domestic types (NEMA, BS1363, Schuko) | Domestic outlets only (NEMA, BS1363, Schuko) |

| Outlet Quantity | Wide range from 4 to 48 outlets | Typically 2 to 8 outlets |

| Inlet Types | Domestic and industrial-grade inlets (IEC 60309, NEMA L6-30P/20P) | Domestic inlets only |

| Cordset Thickness | From 14 AWG up to 6 AWG (1.5 mm² to 10 mm²), thicker cables for higher current capacity | Usually 14 AWG (around 1.5 mm²) |

| Cordset Quantity | Single or dual cordsets/inlets available (for redundancy) | Single cordset only |

| Power Phase Support | Single-phase and three-phase power support | Single-phase power only |

| Customization | Built-to-order options for outlets, inlets, voltage, current, connections, colors | Rarely customizable |

| Usage Environment | Industrial, IT/data centers, rack-mounted equipment | Residential, office, light commercial use |

| Installation | Rack-mounted (vertical 0U, horizontal 1U/2U) | No specific mounting |

| Physical Form Factor | Vertical or horizontal rack mount form factors, steel or extrusion materials | Bar-shaped, plastic construction |

| Safety Devices | Industrial-grade resettable fuses, magnetic circuit breakers, overload protection, EMI filters, RCM, ELCB | Basic surge protection on some models, usually no fuses or circuit breakers |

| Advanced Features | Intelligent PDUs with remote management, metering, environmental sensors, software integration | Basic power distribution, no remote management or monitoring |

| Extra Accessories | Environmental sensors (smoke, temperature, humidity, water leakage), lockable and fused outlets | Generally none |

Key Takeaways:

- PDUs offer a broader range of technical features, including support for higher voltages, more outlets, and advanced safety devices.

- Ordinary power strips focus on basic power extension for home and office use, with limited safety and no remote management.

- PDUs provide customization and redundancy options, making them suitable for mission-critical environments.

- The physical build of a PDU uses steel and supports rack mounting, while power strips use plastic and lack industrial mounting options.

- Advanced PDUs integrate monitoring, metering, and environmental sensors, which are not available in standard power strips.

This comparison highlights how a pdu addresses the needs of high-demand, scalable environments, while ordinary power strips remain best suited for simple, low-risk applications.

Typical Use Cases for PDU and Power Strip

Home Applications

Home environments typically require simple power solutions. Ordinary power strips meet most household needs. Residents use them to connect televisions, gaming consoles, lamps, and chargers. These devices offer flexibility and convenience for temporary setups or rearranged furniture. Surge-protected power strips provide extra safety for sensitive electronics, such as computers or home theater systems.

Tip: Home users should avoid plugging high-wattage appliances, like space heaters or microwaves, into power strips. These devices can overload the strip and create fire hazards.

PDUs rarely appear in residential settings. However, technology enthusiasts or home lab builders sometimes install basic PDUs in dedicated server closets or network racks. These setups benefit from the organized cable management and higher outlet count that PDUs provide.

Common Home Uses:

- Entertainment centers

- Home offices

- Charging stations for multiple devices

- Temporary holiday lighting

Office Applications

Modern offices rely on both power strips and PDUs, depending on the complexity of the workspace. Ordinary power strips serve well for desks, conference rooms, and shared workspaces. Employees use them to power computers, monitors, printers, and phone chargers. Surge-protected models help safeguard valuable office equipment from voltage spikes.

Larger offices or IT rooms often require more robust solutions. PDUs support network racks, server cabinets, and centralized printer stations. Metered or switched PDUs allow IT staff to monitor power usage and control devices remotely. This capability helps prevent downtime and supports efficient energy management.

| Application Area | Preferred Solution | Key Benefit |

|---|---|---|

| Individual desks | Power strip | Flexibility, easy access |

| Server/network racks | PDU (metered/switched) | Monitoring, remote control |

| Conference rooms | Surge-protected strip | Device safety, convenience |

Offices with high equipment density or critical IT infrastructure should consider PDUs for improved safety and scalability.

Industrial and Data Center Applications

Industrial facilities and data centers demand advanced power distribution. PDUs dominate these environments. They deliver stable, high-capacity power to racks of servers, switches, and industrial machinery. Intelligent PDUs provide real-time monitoring, environmental sensors, and remote management. These features help technicians prevent overloads, manage energy consumption, and respond quickly to issues.

Ordinary power strips do not meet the safety or capacity requirements of industrial settings. Their limited protection and lower build quality make them unsuitable for mission-critical operations.

Key PDU Use Cases in Industry and Data Centers:

- Powering server racks and network switches

- Supporting redundant power paths for uptime

- Monitoring energy use and environmental conditions

- Enabling remote power cycling and troubleshooting

Note: Compliance with safety standards and certifications remains essential in industrial and data center environments. PDUs help organizations meet these requirements while ensuring reliable operation.

Advanced PDU Features and Safety Considerations

Overload and Circuit Protection

Modern power distribution units deliver robust protection for sensitive equipment. Unlike ordinary power strips, which mainly rely on basic surge protection, PDUs incorporate multiple layers of defense. Industrial-grade resettable fuses and magnetic circuit breakers form the backbone of their overload and short-circuit protection. When current exceeds safe limits, these mechanisms immediately disconnect power, preventing damage to connected devices and reducing fire risk. Advanced PDUs also integrate thermally protected components that guard against overheating. This multistage approach ensures that even in high-demand environments, equipment remains safe and operational.

Tip: Always select a PDU with built-in circuit breakers for critical infrastructure. This feature provides a reliable safeguard against unexpected electrical faults.

Surge Protection Capabilities

Surge protection plays a vital role in safeguarding electronics from voltage spikes. Many ordinary power strips include built-in surge protectors, which cushion appliances against sudden surges. These devices use components like Metal Oxide Varistors (MOVs) to absorb excess voltage and divert it safely to ground. This method effectively shields home and office devices from transient spikes.

- Ordinary power strips often feature surge protection as a primary safety measure.

- Surge protectors in power strips act as a buffer, protecting appliances from surge damage.

- PDUs typically focus on overload protection, using resettable fuses or magnetic circuit breakers.

- Surge protection in PDUs is less direct and may not match the effectiveness of dedicated surge-protected power strips.

For environments with frequent power fluctuations, users should consider combining PDUs with external surge protection devices to achieve comprehensive coverage.

Remote Monitoring and Management

Intelligent PDUs offer advanced remote monitoring and management capabilities that set them apart from basic power strips. These units support network or serial interface connections, enabling real-time oversight from virtually anywhere. Facility managers can monitor power consumption at both the unit and outlet level, control outlets remotely, and perform functions such as on/off switching, rebooting, and sequential power-up. User-configurable alarms and threshold-based alerts help prevent overloads and downtime.

- Remote access through secure network or serial connections allows for real-time monitoring and control.

- Outlet-level switching enables precise management, including power cycling and scheduled shutdowns.

- Environmental sensors track temperature, humidity, and leaks, providing early warnings for potential hazards.

- Integration with management protocols like SNMP and DCIM platforms centralizes data and streamlines operations.

- Security features such as authentication and encryption protect against unauthorized access.

These advanced features ensure that organizations maintain high reliability, reduce maintenance costs, and respond quickly to emerging issues.

Redundancy and Failover Options

Redundancy and failover options play a crucial role in maintaining uptime for critical environments such as data centers and industrial facilities. These features ensure that power remains available even when a primary source fails. Modern power distribution units (PDUs) often incorporate redundancy models like N, N+1, 2N, and 2N+1. Each model uses key components with built-in redundancy, including uninterruptible power supply (UPS) systems, cooling units, and backup generators. Automatic Transfer Switches (ATS) and logic-controlled switchgear enable immediate failover to backup power sources. This design eliminates single points of failure and minimizes downtime.

| Redundancy Model | Key Components with Redundancy | Failover Mechanism | Contribution to Uptime |

|---|---|---|---|

| N | UPS systems, cooling, backup generators | ATS, logic-controlled switchgear | Eliminates single points of failure; enables immediate failover to backup power, minimizing downtime |

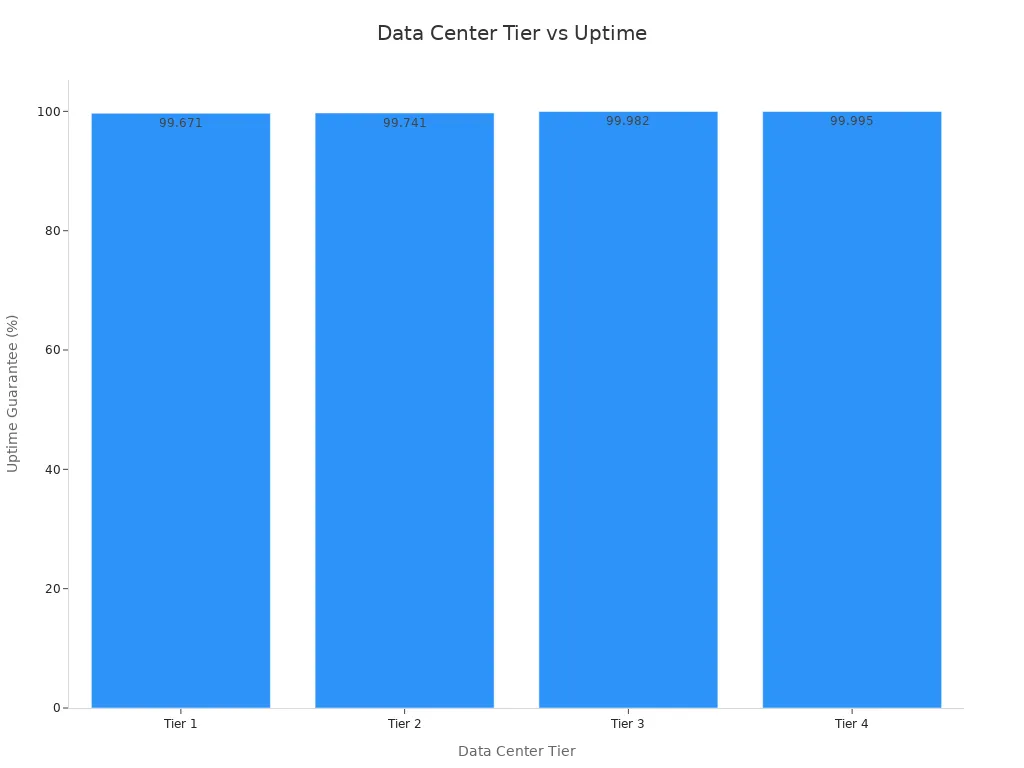

Data centers classify their uptime guarantees by tier, with each level reflecting the role of redundancy and failover:

| Data Center Tier | Uptime Guarantee | Role of Redundancy and Failover |

|---|---|---|

| Tier 1 | 99.671% (up to 28.8 hours downtime/year) | Basic redundancy; limited failover capabilities |

| Tier 2 | 99.741% (up to 22 hours downtime/year) | Increased redundancy and failover support |

| Tier 3 | 99.982% (up to 1.6 hours downtime/year) | Concurrent maintainability with robust redundancy and failover |

| Tier 4 | 99.995% (up to 26.3 minutes downtime/year) | Fault-tolerant design with full redundancy and automatic failover |

A Tier 4 facility, for example, uses a fault-tolerant design that supports full redundancy and automatic failover. This approach guarantees the highest level of uptime, which is essential for mission-critical operations. By integrating these advanced features, a pdu helps organizations achieve high availability and operational continuity.

🛡️ Tip: Always select a PDU with ATS and dual power inlets for environments where uptime is non-negotiable.

Compliance and Certification Standards

Compliance and certification standards ensure that power distribution equipment meets strict safety, reliability, and performance requirements. Regulatory bodies such as Underwriters Laboratories (UL), the International Electrotechnical Commission (IEC), and the Canadian Standards Association (CSA) set these benchmarks. A PDU that carries UL 60950-1 or IEC 62368-1 certification has passed rigorous testing for electrical safety and fire resistance.

Manufacturers must also comply with local codes, such as the National Electrical Code (NEC) in the United States. These standards address wiring methods, grounding, and installation practices. In addition, many organizations require PDUs to meet RoHS (Restriction of Hazardous Substances) and CE (Conformité Européenne) directives, which limit hazardous materials and ensure product safety within the European Economic Area.

Power strips and PDUs intended for use in data centers or industrial environments often display certification labels. These marks provide assurance that the device will perform reliably under demanding conditions. Facility managers should always verify compliance before deploying new power distribution equipment.

⚠️ Note: Non-compliant devices may pose safety risks and could lead to regulatory penalties or insurance issues.

Choosing Between PDU and Power Strip for Modern Power Needs

Assessing Power Requirements

Selecting the right power distribution solution starts with a careful assessment of power needs. Users must evaluate several factors to ensure reliable and safe operation. The following steps help guide this process:

- Type of Power and Connector Compatibility: Identify whether the environment requires AC or DC power. This decision impacts the choice of connectors and the overall circuit design. Compatibility with both the power source and connected devices remains essential.

- Power Outputs Capacity: Count the number of devices that need power. Choose a solution with enough outlets to support all equipment, plus additional capacity for future growth. Insufficient outlets can restrict flexibility and limit expansion.

- Handling Redundant Power Supplies: Many critical devices, such as servers, feature multiple power inputs. Select a solution that allows grouping of outlets, enabling simultaneous control and remote rebooting of all power supplies.

- Physical Mounting Options: Consider the available space and installation environment. Options include rack-mounted, side-mounted, or wall-mounted units. The right mounting method improves cable management and optimizes space.

- Additional Features: Advanced units offer remote power cycling, environmental monitoring, and alarm notifications. These features prove valuable for managing power in remote or unmanned locations.

⚡ Tip: Always plan for a margin above current needs to accommodate unexpected equipment or future upgrades.

Device Compatibility Considerations

Device compatibility plays a crucial role in the decision-making process. Users must match the power distribution unit’s outlets and form factor to the requirements of their equipment. Several key points guide this evaluation:

- Different devices require specific outlet configurations and support for various voltages and amperages. For example, some equipment operates on 120V, while others need 208V circuits.

- Matching receptacles to device plugs ensures proper power delivery and reduces the risk of connection errors.

- Power distribution units come in multiple form factors, such as horizontal or vertical designs. Compatibility with rack or cabinet dimensions is essential for a secure fit.

- Vertical units vary in length and outlet arrangement. Users should verify that the chosen unit fits within the available rack space.

- Advanced units offer features like monitoring, metering, and remote control. These capabilities support complex device compatibility needs and enable efficient management.

- The number and type of outlets should match current devices, with extra outlets available for future additions.

A careful review of these factors helps prevent installation issues and ensures seamless integration with existing equipment.

Planning for Future Scalability

Modern environments often experience rapid growth in power demands. Planning for scalability ensures that the chosen solution remains effective as needs evolve. Several strategies support this goal:

- Modular units allow users to expand or modify the system by adding or swapping modules, eliminating the need for complete replacement.

- Intelligent units with remote management and real-time monitoring help track energy use, balance loads, and adjust settings as requirements change.

- Leaving space and capacity for future equipment additions prevents costly upgrades and disruptions.

- Three-phase power distribution increases power density and improves load balancing, reducing the complexity of cabling.

- Hot-swappable components and support for multiple input voltages enable adaptation to new technologies without downtime.

- Designing layouts with scalability in mind accommodates network growth and changing infrastructure needs.

🛠️ Note: Staying informed about emerging technologies and standards in power distribution helps maintain flexibility and supports long-term growth.

Budget and Cost-Benefit Analysis

Organizations must balance initial investment with long-term value when selecting between a power distribution unit and a power strip. The decision involves more than just the purchase price. It requires a careful review of operational needs, reliability, and the potential for future savings.

The following table outlines the cost levels, features, and best-use scenarios for each device type:

| Device Type | Cost Level | Key Features & Benefits | Use Cases & Considerations |

|---|---|---|---|

| Basic PDU | Low (Cost-effective) | Simple power distribution, no advanced monitoring or remote management | Suitable for budget-conscious operations, small to medium data centers; reliable but lacks advanced features |

| Metered PDU | Moderate | Real-time power usage monitoring, local digital display, overload prevention | Ideal for data centers needing energy optimization and overload prevention; balances cost and functionality |

| Monitored/Switched/Smart PDUs | High | Advanced remote management, outlet-level monitoring, integration with DCIM software | Best for high-density data centers requiring detailed control and monitoring; higher upfront cost and setup complexity |

| Basic Power Strip | Lowest | No advanced features, simple power distribution | Not recommended for critical IT equipment due to lack of reliability and monitoring |

A basic power strip offers the lowest upfront cost but provides minimal protection and no monitoring. This option suits non-critical environments where downtime poses little risk. In contrast, a basic pdu delivers reliable power distribution for small to medium data centers at a modest price. Metered and smart PDUs require a higher investment but offer significant benefits, such as energy optimization, remote management, and reduced downtime. These features can lead to substantial savings over time by preventing costly outages and improving operational efficiency.

💡 Tip: Decision-makers should weigh the upfront cost against potential savings from energy efficiency, reduced downtime, and improved control. The right choice depends on the environment’s need for monitoring, scalability, and integration.

Prioritizing Safety and Compliance

Safety and compliance remain critical factors in selecting power distribution equipment. Organizations must ensure that every device meets industry standards and supports reliable, safe operation.

- Compliance with standards such as FCC Part 15 Class A, TUVus, IEC 62368, CE, and UKCA ensures that devices meet strict safety, performance, and reliability requirements.

- Standards developed by organizations like NEMA support global compatibility and consistent quality.

- Choosing devices with these certifications guarantees adherence to rigorous safety and performance criteria.

Routine maintenance and monitoring further enhance safety:

- Regular inspections help identify potential issues early, preventing costly failures.

- Predictive maintenance with embedded sensors provides real-time insights into device health.

- Continuous monitoring offers 24/7 protection and reduces unnecessary maintenance.

- Advanced alarm and fault detection systems enable early identification of power issues, minimizing downtime.

Proper sizing and configuration also play a vital role:

- Selecting the correct power output capacity prevents overloading and ensures uninterrupted supply.

- Adding a 20-30% buffer to power requirements allows for future expansion and unexpected surges.

- Universal connector types, such as C13 and C19 outlets, simplify deployment and ensure compatibility.

- Appropriate mounting configurations, whether horizontal or vertical, support installation needs and optimize space.

Redundancy features protect critical operations:

- Redundant power supplies and UPS systems ensure uninterrupted power during disruptions.

- These features minimize downtime and prevent data loss in sectors like data centers, telecommunications, and healthcare.

Environmental and project-specific considerations guide final selection:

- Assess the installation environment, including indoor or outdoor use and exposure to weather.

- Identify project requirements such as power load, circuit layout, and safety levels.

- Consider the duration of use. Temporary events require flexible, quick-install solutions with weather resistance. Permanent installations demand durability, energy efficiency, and strict regulatory compliance.

⚠️ Note: Prioritizing certified, properly sized, and regularly maintained equipment helps organizations achieve safe, reliable, and compliant power distribution.

PDUs and ordinary power strips serve distinct roles in modern power management. PDUs deliver advanced features such as real-time energy tracking, remote monitoring, and load balancing, making them essential for data centers and high-density environments. In contrast, ordinary power strips offer basic power extension for homes or small offices. To choose the right solution, users should:

- Assess total power requirements and future scalability.

- Match outlet types and connector compatibility with equipment.

- Consider redundancy and mounting options for reliability.

- Select smart PDUs for environments needing monitoring and control.

Choosing the correct device ensures safe, efficient, and scalable power distribution tailored to each environment.

FAQ

What is the main difference between a PDU and a power strip?

A PDU manages and distributes power for high-demand environments like data centers. A power strip extends outlets for basic home or office use. PDUs offer advanced features such as monitoring and overload protection. Power strips focus on convenience and simple power extension.

Can I use a power strip in a data center?

A power strip does not meet the safety or capacity requirements for data centers. Data centers require PDUs for reliable, scalable, and safe power distribution. Using a power strip in these environments increases the risk of overload and equipment failure.

Do PDUs provide surge protection?

Most PDUs do not include built-in surge protection. They focus on overload and circuit protection. For environments with frequent surges, users should pair PDUs with dedicated surge protection devices for complete safety.

How do I choose the right PDU for my equipment?

Users should assess total power needs, outlet types, and future expansion plans. They must ensure compatibility with equipment voltage and connector types. Advanced features like remote monitoring or redundancy may benefit critical environments.

Are smart power strips a good alternative to PDUs?

Smart power strips offer remote control and energy-saving features for home or office use. They do not match the capacity, durability, or advanced management features of PDUs. For critical or high-density setups, PDUs remain the preferred choice.

What safety certifications should I look for?

Look for certifications such as UL, IEC, CE, or CSA. These marks indicate compliance with strict safety and performance standards. Certified devices reduce risks and ensure reliable operation in demanding environments.

Can I daisy-chain power strips or PDUs?

Daisy-chaining power strips or PDUs creates serious fire and overload hazards. Manufacturers strongly advise against this practice. Always connect devices directly to a properly rated outlet or circuit.

When should I upgrade from a power strip to a PDU?

Upgrade to a PDU when equipment count, power demand, or reliability needs exceed what a power strip can handle. Signs include frequent tripping, lack of monitoring, or the need for remote management and scalability.