Selecting the right MPO Patch Panel manufacturer plays a crucial role in the success of telecom projects. The global fiber adapter panel market, valued at $1.2 billion in 2023, is projected to reach $2.7 billion by 2032, growing at a 9.4% CAGR. This growth highlights the increasing demand for high-speed connectivity and robust data center infrastructure. Manufacturers adhering to industry standards ensure compatibility, reliability, and seamless integration with various networking equipment. Their compliance fosters interoperability, enhancing flexibility across systems while supporting efficient network management.

Key Takeaways

- Pick makers that use strong materials for long-lasting products. This helps your MPO Patch Panel handle tough conditions and stay durable.

- Check if it works with your current systems. Make sure the panel matches your network’s connectors and needs to prevent signal problems.

- Choose makers with good customer help. Good support can fix problems fast and reduce delays.

Understanding MPO Patch Panels

What is an MPO Patch Panel?

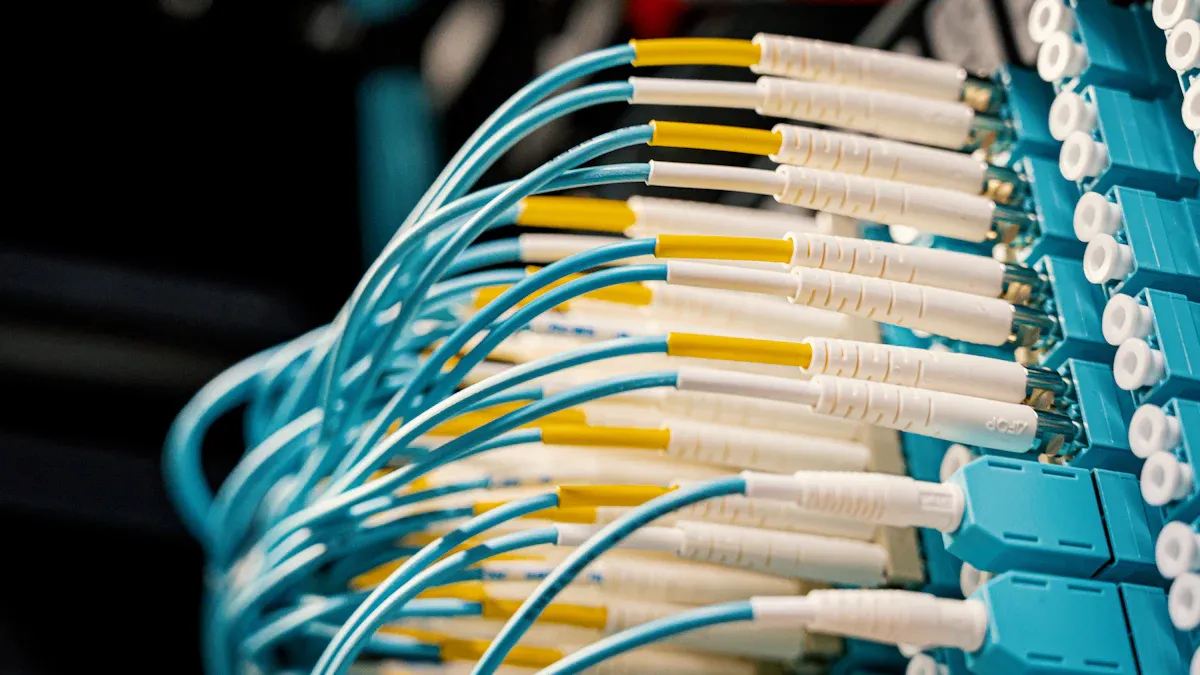

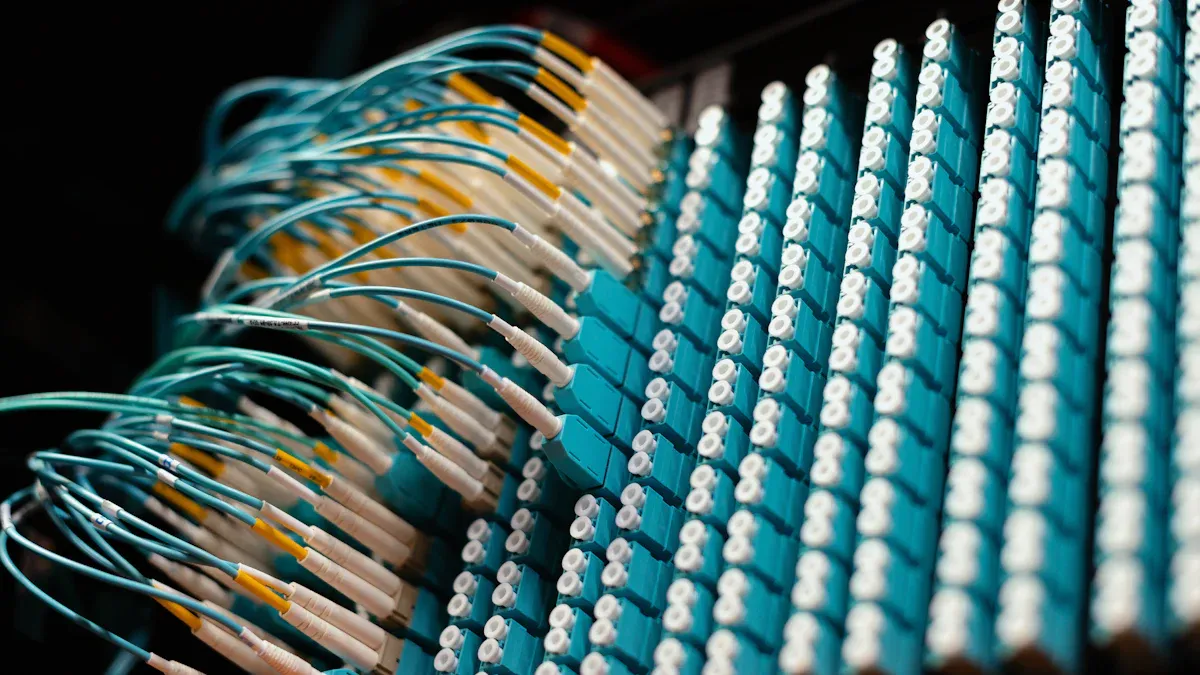

An MPO Patch Panel is a critical component in modern fiber optic networks. It serves as a centralized hub for managing multiple optical fiber connections, enabling efficient routing and organization. MPO stands for "Multi-Fiber Push-On," referring to the connector type that allows multiple fibers to be housed within a single interface. These panels are designed to accommodate high-density connections, making them ideal for data centers and telecom facilities where space and performance are paramount.

Key features of MPO Patch Panels include:

- High-Density Design: They support multi-fiber arrays, maximizing fiber capacity within limited physical space.

- Ease of Maintenance: Transparent lids and enhanced labeling simplify troubleshooting and upgrades.

- Compatibility: MPO connectors are interchangeable across brands, ensuring seamless integration with existing systems.

In industry literature, MPO Patch Panels are often described using metrics such as fiber alignment accuracy, high-speed data transmission capabilities, and low insertion loss. These metrics highlight their role in ensuring reliable and efficient network performance.

| Metric | Description |

|---|---|

| Fiber Alignment Accuracy | Depends on fiber eccentricity, spacing, and precision of guide pins. |

| High-Density Design | Uses multi-fiber arrays to fit more fibers into limited space. |

| High-Speed Data Transmission | Supports 40G/100G applications, ensuring efficient data transmission with optical transceivers. |

| Flexibility | Designed to withstand various environmental factors based on application needs. |

| Interchangeability | Connectors from different brands can be used interchangeably, simplifying integration. |

| Low Insertion Loss | Advanced polishing techniques ensure efficient optical signal transmission. |

The Role of MPO Patch Panels in Telecom Projects

MPO Patch Panels play a pivotal role in telecom projects by enhancing network efficiency and scalability. Their ability to centralize fiber connections reduces clutter and simplifies cable management, which is essential for maintaining organized and reliable infrastructure.

The growing reliance on cloud computing and IoT has amplified the need for high-speed data transfer and robust connectivity. MPO Patch Panels address these demands by supporting high-density optical fiber connections and facilitating seamless integration with high-speed protocols like 40G and 100G.

Benefits of MPO Patch Panels in telecom projects include:

- Improved Organization: They centralize cables, reducing errors during upgrades and expansions.

- Simplified Maintenance: Easy access to connections minimizes downtime during troubleshooting.

- Scalability: Modular designs allow for the addition and reconfiguration of connections as network demands grow.

| Feature | Description |

|---|---|

| Overall Size | 1.5U with ½ RU individual trays |

| Fiber Capacity | Up to 144FO in LC on 1.5U Space |

| Mounting Type | Standard 19” or 21” Rack |

| Material | High durability & lightweight PC & PC+Fiber Glass |

| Maintenance | Transparent lid for easier maintenance |

| Labeling | Enhanced labeling for better identification |

| Adapter Options | Available in shuttered dust-proof LC adapters, SM and MM options |

| Installation | Simple and easy installation with integrated fiber routing |

| Access Type | Right or Left Hinged Swing-out |

| Cable Management | Front manager with Hinged transparent drop-down door |

These panels are indispensable in data centers and telecommunication facilities, where they ensure efficient management of optical fiber connections. Their modular design and high-density capabilities make them suitable for handling the increasing demands of modern networks.

Key Considerations for Choosing an MPO Patch Panel Manufacturer

Ensuring Product Quality and Durability

The quality and durability of an MPO Patch Panel directly impact the reliability of a telecom network. Manufacturers should use high-grade materials, such as polycarbonate or fiber-reinforced plastics, to ensure panels withstand environmental stress and prolonged use. Panels designed for outdoor installations must feature weatherproofing and UV resistance to prevent degradation.

When evaluating durability, consider the panel’s ability to maintain performance under heavy usage. For instance, high-density designs should support frequent connections and disconnections without compromising fiber alignment accuracy. A robust panel minimizes downtime and reduces maintenance costs, making it a critical investment for long-term projects.

Compatibility with Existing Systems and Standards

Compatibility ensures seamless integration of the MPO Patch Panel with existing network infrastructure. Panels must align with the polarity, connector types, and performance requirements of the system. For example, mismatched connectors can lead to signal loss and inefficiencies.

The table below highlights key factors to assess compatibility:

| Factor | Description |

|---|---|

| Panel Location | Consider installation environment (indoor or outdoor) and protection against elements. |

| Panel Compatibility | Ensure alignment with polarity, performance, and connector type for optimal connectivity. |

| Panel Capacity | Evaluate load requirements to avoid overloading, choosing between loaded and unloaded panels. |

| Panel Design | Select designs (enclosed, open, full-depth) based on specific needs. |

| Panel Density | Assess the number of ports per rack unit, especially for server room installations. |

Importance of Certifications and Compliance

Certifications validate the manufacturer’s adherence to industry standards, ensuring the panel’s performance and reliability. Standards like TIA-568 and ISO/IEC 11801 guarantee compatibility and scalability in high-speed data transmission.

The table below outlines essential certifications and their significance:

| Standard | Importance |

|---|---|

| TIA-568 | Ensures compatibility and efficiency in telecommunication systems, preventing signal loss. |

| IEC 61754-7 | Guarantees MPO connectors meet strict norms for performance and reliability. |

| ISO/IEC 11801 | Facilitates scalability, allowing adjustments to evolving technology needs. |

Choosing a certified manufacturer reduces risks associated with non-compliance, such as network failures or costly upgrades.

Evaluating Customer Support and After-Sales Service

Reliable customer support ensures smooth implementation and maintenance of MPO Patch Panels. Manufacturers offering comprehensive after-sales services, such as installation guidance and troubleshooting, add significant value.

Evaluate the availability of technical support, warranty policies, and response times. A manufacturer with a dedicated support team can address issues promptly, minimizing disruptions. Additionally, extended warranties reflect the manufacturer’s confidence in their product’s quality.

Tip: Opt for manufacturers with a proven track record of responsive and knowledgeable customer service teams.

How to Evaluate MPO Patch Panel Manufacturers

Researching Manufacturer Reputation and Reviews

A manufacturer’s reputation often reflects the quality and reliability of its products. Researching reviews and testimonials from industry professionals provides valuable insights into the manufacturer’s performance. Look for feedback on product durability, ease of installation, and customer service responsiveness.

Online platforms, such as industry forums and review websites, are excellent resources for gathering unbiased opinions. Additionally, case studies and success stories from previous clients can highlight the manufacturer’s ability to meet project-specific requirements. Manufacturers with a long-standing presence in the market and a history of successful projects often demonstrate greater reliability and expertise.

Tip: Prioritize manufacturers with consistently positive reviews and a proven track record in delivering high-quality MPO Patch Panels.

Assessing Testing and Quality Assurance Processes

Thorough testing and quality assurance processes ensure that MPO Patch Panels meet industry standards and perform reliably under various conditions. Manufacturers should implement rigorous quality control measures at every stage of production.

Key quality assurance stages include:

- Incoming Quality Control (IQC): Verifies that raw materials meet specifications before production begins.

- In Process Quality Control (IPQC): Monitors production processes to maintain consistent quality.

- Final Quality Control (FQC): Conducts inspections to ensure finished products meet performance standards.

- Outgoing Quality Control (OQC): Confirms that products comply with quality benchmarks before delivery.

| Quality Control Stage | Description |

|---|---|

| Incoming Quality Control | Ensures materials meet specifications before production. |

| In Process Quality Control | Monitors production processes to maintain quality. |

| Final Quality Control | Conducts final inspections before products are shipped. |

| Outgoing Quality Control | Verifies that products meet quality standards before delivery. |

Manufacturers should also adhere to international standards, such as IEC 61300-3-35, which ensures connector quality. Third-party certifications further validate the reliability of their testing processes.

Note: Testing benchmarks, such as Tier 1 testing, provide critical data on loss, length, and polarity, ensuring the panel’s performance aligns with project requirements.

Comparing Panel Design, Capacity, and Density

The design, capacity, and density of an MPO Patch Panel significantly impact its suitability for specific telecom projects. Manufacturers offer various designs, including enclosed, open, and modular panels, each catering to different installation environments.

When comparing panel capacity, consider the number of fibers the panel can accommodate. High-density panels are ideal for data centers with limited space, while lower-density options may suffice for smaller installations. Evaluate the number of ports per rack unit to determine the panel’s efficiency in utilizing available space.

| Feature | Description |

|---|---|

| Panel Design | Options include enclosed, open, and modular designs for different needs. |

| Fiber Capacity | High-density panels support more fibers, ideal for space-constrained areas. |

| Port Density | Higher port density maximizes space utilization in server rooms. |

Manufacturers that offer customizable designs provide greater flexibility, allowing the panel to adapt to evolving network demands. Transparent lids, enhanced labeling, and integrated cable management features further simplify maintenance and upgrades.

Verifying Warranty and Support Policies

Warranty and support policies reflect a manufacturer’s confidence in their products and commitment to customer satisfaction. A comprehensive warranty ensures protection against manufacturing defects, while robust support policies facilitate smooth implementation and maintenance.

Evaluate the manufacturer’s response time and the availability of technical support. A dedicated support team can address issues promptly, minimizing network downtime. Extended warranties and post-sales services, such as installation guidance and troubleshooting, add significant value to the investment.

Tip: Choose manufacturers that offer clear warranty terms and responsive customer support to ensure long-term reliability and peace of mind.

Choosing a reliable MPO patch panel manufacturer ensures the success of telecom projects. High-quality panels improve network efficiency and scalability. Key factors include product durability, system compatibility, and responsive customer support.

- High-density panels enable efficient data transmission.

- Modular designs allow future expansions.

- Stable connections reduce downtime.

Prioritize manufacturers with proven expertise and performance.

FAQ

What is the typical lifespan of an MPO patch panel?

High-quality MPO patch panels typically last 10-15 years. Their lifespan depends on material quality, environmental conditions, and proper maintenance.

How can a manufacturer’s certifications impact project success?

Certifications ensure compliance with industry standards. They guarantee compatibility, reliability, and performance, reducing risks of network failures or costly upgrades.

Are modular MPO patch panels better for scalability?

Yes, modular designs allow easy expansion and reconfiguration. They adapt to growing network demands, making them ideal for scalable telecom projects.