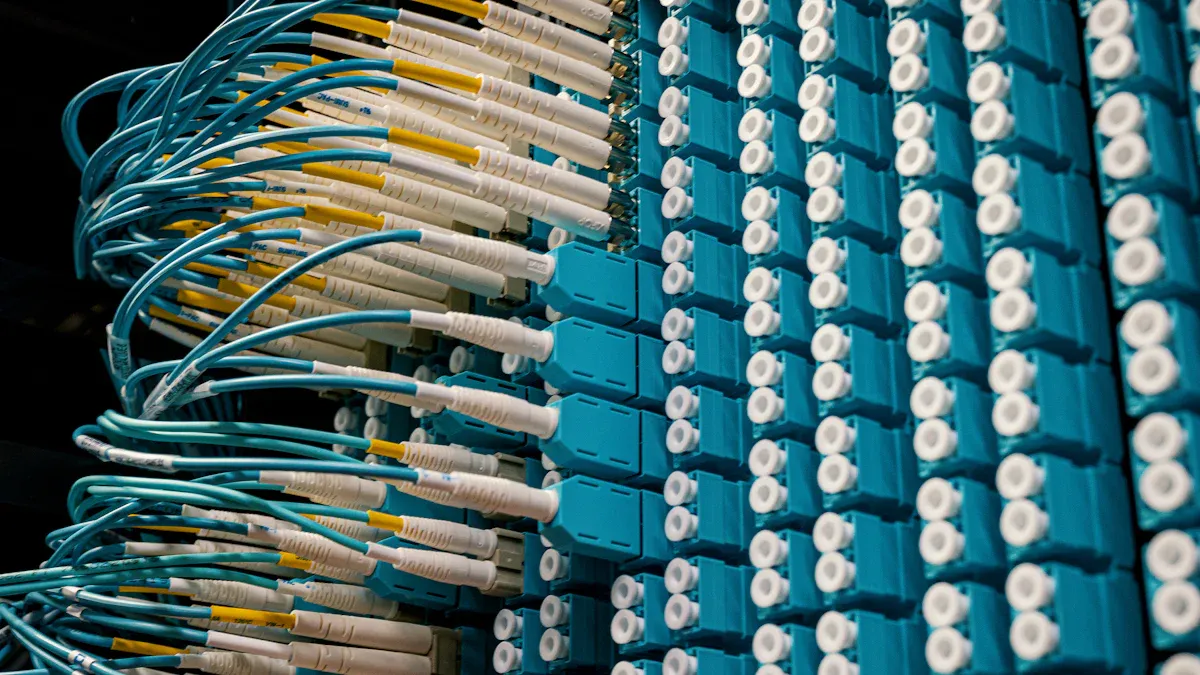

Optimized MPO trunk assemblies deliver peak data center performance. The global MPO trunk cable market, valued at $2.3 billion in 2024, highlights the growing importance of these solutions. It projects growth to $4.5 billion by 2035. Maximizing efficiency and reliability in high-density network infrastructure is crucial. Network-related issues cause 12% of significant data center outages. They also account for 30% of end-to-end IT service outages. Proper connectivity, including a high-quality MPO/MTP 패치 리드 또는 코드 SM, prevents costly downtime. It ensures seamless data flow.

주요 테이크 아웃

- 권리를 선택하십시오 MPO 트렁크 케이블. Consider fiber type, count, and durability for your network needs.

- Install MPO trunk cables carefully. Proper routing, cleaning, and secure connections prevent signal loss.

- Test MPO trunk links thoroughly. Use tools like OLTS and OTDR to find and fix problems early.

- Maintain MPO trunk infrastructure regularly. Inspect cables, clean connectors, and control the environment.

- Plan for future network growth. Use modular designs and follow new standards for long-term success.

1. Strategic Selection of MPO Trunk Cables

Selecting the correct MPO trunk cables forms the foundation of a high-performing network. This decision impacts network efficiency, scalability, and long-term reliability. Careful consideration of fiber type, fiber count, connector polarity, and cable durability is essential for optimal data center operations.

Choosing the Right Fiber Type for MPO Trunk Performance

The choice between single-mode and multi-mode fiber significantly affects network reach and bandwidth capabilities. Each type serves distinct application requirements.

Single-Mode Fiber for Long-Haul MPO Trunk Connections

Single-mode fiber features a small core diameter, typically 8-10 microns. This design allows light to travel along a single path, minimizing signal dispersion. Single-mode MPO trunk cables enable transmission distances up to several kilometers. They also offer increased bandwidth, making them ideal for long-haul and telecommunication applications. For high-performance single-mode connections, specific optical characteristics are crucial.

| Category | Insertion Loss (dB) | Return Loss (dB) |

|---|---|---|

| General Single-mode | N/A | > 45 |

| 100G Networks | < 0.35 per connector | > 35 |

| 12 Fiber | ≤ 0.35 (elite ≤ 0.15) | ≥ 60 |

| 24 Fiber | ≤ 0.35 per row | ≥ 60 per row |

Multi-Mode Fiber for Shorter Reach MPO Trunk Applications

Multi-mode MPO cables have a larger core diameter, either 50 or 62.5 microns. This allows multiple light modes to transmit simultaneously. Multi-mode fiber supports high-speed transmission up to 600 meters. Data centers and local area networks (LANs) primarily use these cables for shorter distances. They are not suitable for long-distance applications.

Optimizing MPO Trunk Fiber Counts and Configurations

Fiber count and configuration directly influence network density and future expansion possibilities. Choosing the right count ensures efficient use of space and resources.

12-Fiber MPO Trunk for Standard Deployments

The 12-fiber MPO connector has been an industry standard for over a decade. It dominates many network deployments. Its primary application is in 100G Ethernet (100GBASE-SR4). This uses 8 fibers (4 for transmit, 4 for receive) and leaves 4 fibers available. It also supports 40G BiDi (40GBASE-SR-BiDi) using WDM over just 2 fibers within a 12-fiber MPO. This standard offers a good balance of density and compatibility. A vast ecosystem of related products supports it.

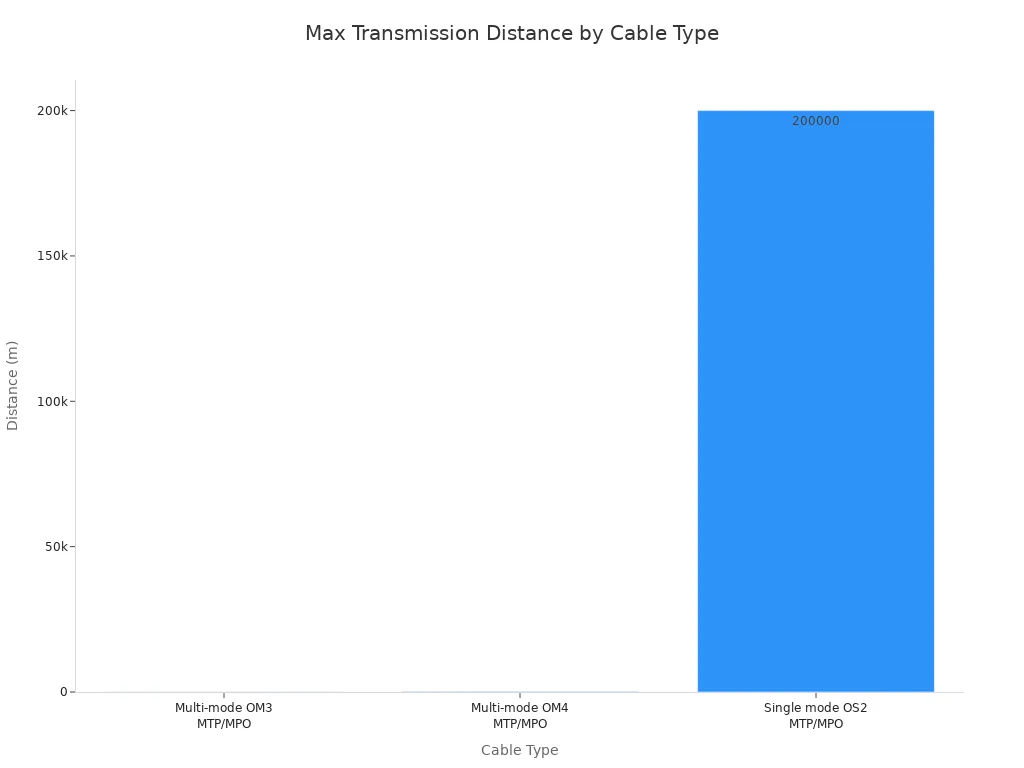

| 케이블 유형 | 애플리케이션 | Max Transmission Distance |

|---|---|---|

| 12-fiber MTP/MPO (general) | 10G-40G, 40G-100G connections | N/A |

| Multi-mode OM3 MTP/MPO | Short-distance transmission, Buildings, Campus | 100m |

| Multi-mode OM4 MTP/MPO | Short-distance transmission, Buildings, Campus | 150m |

| Single mode OS2 MTP/MPO | Long-distance transmission, Carrier Networks, MANs, & PONs | 200km |

24-Fiber MPO Trunk for Higher Density Needs

For higher density requirements, 24-fiber MPO cables offer increased capacity within a similar footprint. These cables are often chosen for 400G Ethernet deployments and other applications demanding maximum fiber utilization. They provide a clear path for future network upgrades.

Understanding MPO Trunk Connector Polarity and Keying

Correct polarity ensures signals transmit and receive properly. Incorrect polarity leads to connectivity issues.

Type A, B, and C Polarity for MPO Trunk Systems

Industry standards govern proper polarity for MPO trunk cables. These standards ensure output remains on the transmitter ends and is received by the appropriate receiver ends. ANSI/TIA-568-C.0 confirms fiber polarity alignment (Type A, B, or C) in network designs. Adherence to these standards is essential to prevent loss of connectivity and signals. The TIA/EIA-568-B industry standards explicitly mention governing proper polarity. This is crucial for maintaining network stability and preventing connectivity issues.

Key-Up vs. Key-Down Orientation in MPO Trunk Assemblies

MPO connectors feature a key on one side. This key determines the connector’s orientation when inserted. "Key-up" and "key-down" orientations dictate how the fibers align within the connector. This physical orientation works in conjunction with the polarity type to ensure correct signal flow.

Assessing MPO Trunk Cable Jacket Ratings and Durability

Cable jacket ratings and durability are critical factors for any robust network infrastructure. They ensure both operational safety and long-term performance. Proper selection of these cable characteristics prevents physical damage and maintains data integrity across the network. Installers must thoroughly understand these specifications for reliable and compliant deployments. Ignoring these details can lead to costly failures and safety risks.

Plenum vs. Riser Rated MPO Trunk Cables

Buildings contain specific fire safety zones, each with distinct requirements for cabling. Plenum spaces are areas used for air circulation, such as dropped ceilings or raised floors. Cables installed in these plenum environments require special jackets. Plenum-rated cables produce low smoke and exhibit low flame spread characteristics. This design prevents the rapid spread of fire and toxic fumes through a building’s ventilation systems. Riser spaces, conversely, are vertical shafts or conduits that connect different floors. Riser-rated cables resist flame propagation. They prevent fire from traveling vertically between building levels. Installers must select the correct cable rating for each specific environment. This ensures strict compliance with local building codes. It also protects both personnel and valuable equipment. Using the wrong cable type, such as a riser cable in a plenum space, creates significant fire hazards and violates safety regulations. Always verify the cable’s rating before installation.

Bend Radius and Strain Relief for MPO Trunk Longevity

Fiber optic cables, including MPO trunk assemblies, have a defined minimum bend radius. This represents the smallest curve a cable can form without causing internal damage. Bending a cable too sharply causes micro-bends within the optical fibers. These micro-bends lead to significant signal loss. They can also permanently damage the delicate optical fibers, requiring costly replacement. Installers must always respect the specified minimum bend radius. Cable manufacturers provide this crucial information in their product specifications. Proper strain relief protects cables from excessive tension and physical stress. Excessive pulling, sharp bending, or improper clamping stresses the fibers and connectors. Strain relief mechanisms prevent this undue stress. Cable management accessories play a vital role in maintaining proper routing. These include cable trays, conduits, and appropriate cable ties. Implementing these practices extends the lifespan of the cable. They ensure consistent and reliable network performance over many years. This careful handling preserves the cable’s optical properties.

2. Precision Installation for Optimal MPO Trunk Connectivity

Precision installation is vital for achieving optimal performance from MPO trunk assemblies. Careful handling and correct procedures prevent signal loss and ensure network reliability. Following best practices during installation saves time and resources in the long run.

Best Practices for MPO Trunk Cable Routing and Management

Proper cable routing and management protect the physical integrity of fiber optic cables. This prevents damage that can lead to network issues.

Preventing Kinks and Stress Points in MPO Trunk Cables

Installers must avoid tight bends, twists, or excessive pulling of cables. They should always adhere to the manufacturer’s minimum bend radius specifications. For example, single-mode cables often require a 30mm bend radius, while multi-mode cables may need 10mm. Bending cables too sharply can cause micro-bends, leading to significant signal degradation.

Utilizing Cable Trays and Raceways for MPO Trunk Protection

Cable trays and raceways provide organized pathways for fiber optic cables. These structures protect cables from physical damage, such as crushing or accidental cuts. They also help maintain the correct bend radius throughout the cable run. This organized approach simplifies future maintenance and upgrades.

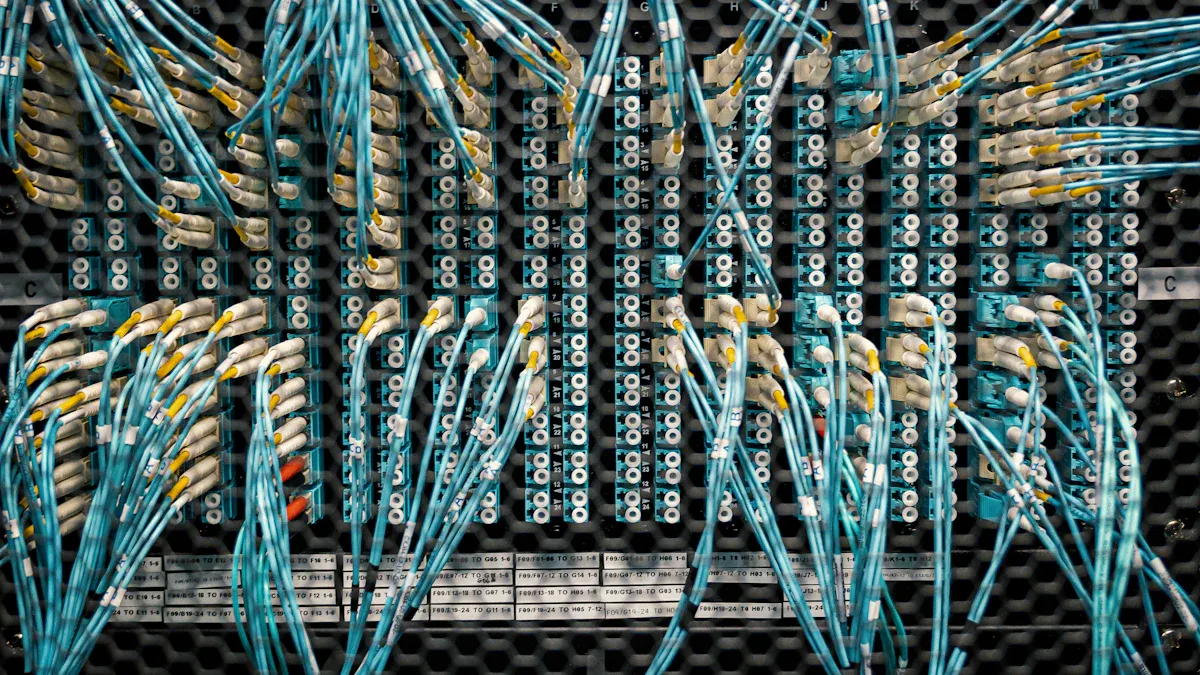

Essential MPO Trunk Connector Cleaning Protocols

Clean connectors are fundamental for reliable fiber optic performance. Contamination is the leading cause of fiber failures.

Importance of Inspection and Cleaning Tools for MPO Trunk Connectors

A single particle on a fiber endface causes signal loss and reflections. This leads to high error rates and degraded network performance. Contamination can also damage expensive optical equipment. As network speeds increase, loss budgets become tighter. This makes dirt and dust significant enemies of higher-speed data transmission. Therefore, inspection and cleaning tools are critical.

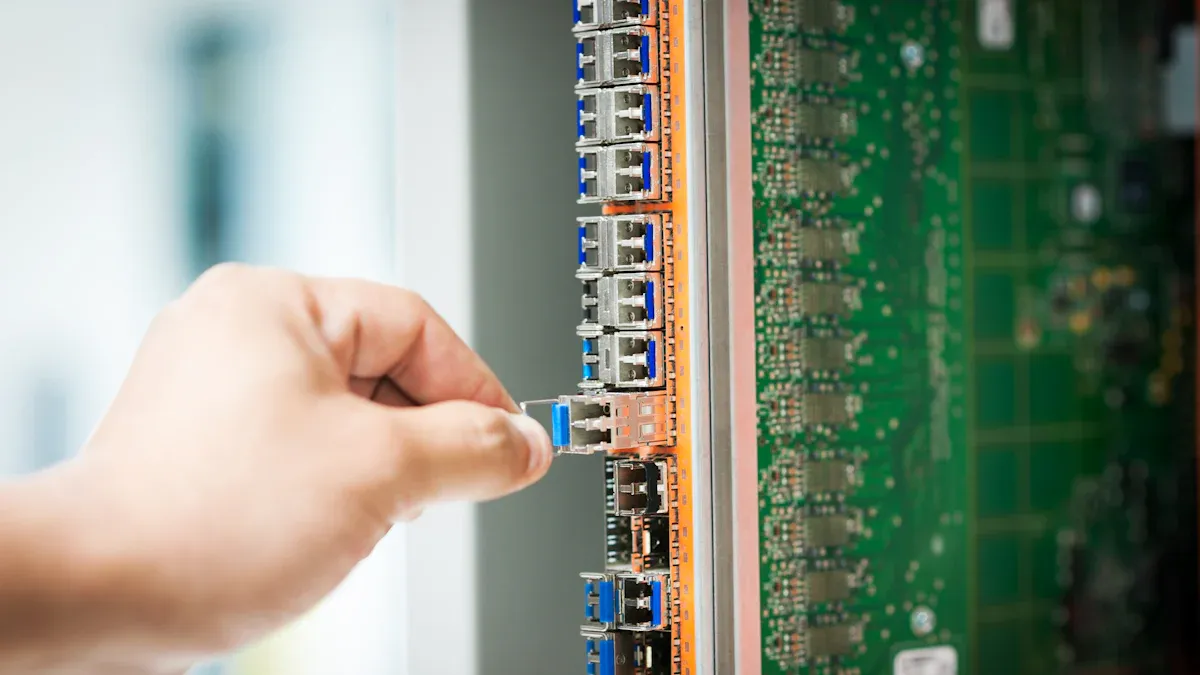

Step-by-Step Guide for MPO Trunk Connector Cleaning

Cleaning MPO connectors requires specific tools and methods. A mechanical cleaner, such as the Fluke Networks QuickClean MPO Cleaner, works for both UPC and APC MPO/MTP connectors. To clean a bulkhead connector, remove the guide cap from the cleaner. For a connector on a fiber cable, remove only the tip of the cap. Push the cleaner into the connector until an audible click is heard, then remove it. After cleaning, use a fiber microscope, like the FI-1000 FiberInspector Microscope with an MPO probe tip, to inspect the connector. Repeat cleaning and inspection if necessary. Lint-free wipes and isopropyl alcohol are also suitable for cleaning.

Ensuring Secure MPO Trunk Connection Practices

Secure connections prevent signal interruptions and maintain network stability. Proper connection practices are non-negotiable.

Verifying Full Seating and Latching of MPO Trunk Connectors

Installers must ensure LC connectors click into place. MPO connectors must be properly seated in adapters or modules. A secure connection means the connector is fully engaged and latched. This prevents accidental dislodgement and ensures optimal signal transfer.

Techniques to Prevent Accidental Disconnections of MPO Trunk Cables

Several factors can cause accidental disconnections. These include contamination on connector end faces, misalignment of connectors, and poor connector quality. Improper handling, physical damage, and compatibility issues also contribute. Proper labeling reduces downtime and prevents accidental disconnections during maintenance.

3. Comprehensive Testing and Validation of MPO Trunk Links

Thorough testing and validation of MPO trunk links are crucial for ensuring network reliability and performance. This step identifies potential issues before they impact operations. Proper testing confirms that the installed infrastructure meets industry standards and supports high-speed data transmission.

Performing End-to-End Link Loss Testing for MPO Trunk Assemblies

End-to-end link loss testing provides a fundamental assessment of fiber optic cable performance. It measures the total optical power loss across a complete fiber link.

Using Optical Loss Test Sets (OLTS) for MPO Trunk Verification

Optical Loss Test Sets (OLTS) are essential tools for verifying MPO trunk assemblies. An OLTS measures the insertion loss of a fiber optic link. It sends a light signal from one end and measures the power received at the other. Technicians use OLTS devices to confirm that the signal strength remains within acceptable limits. This ensures the link can support the intended applications.

Interpreting Test Results Against Industry Standards for MPO Trunk Links

Interpreting OLTS results requires comparing measured loss values against industry standards. TIA/EIA-568 and ISO/IEC 11801 define maximum allowable insertion loss for various fiber types and connector combinations. A link passes if its measured loss is below the specified budget. Exceeding the loss budget indicates a problem requiring further investigation.

Advanced Optical Time Domain Reflectometer (OTDR) Analysis for MPO Trunk

An Optical Time Domain Reflectometer (OTDR) offers a more detailed analysis of fiber optic links. It provides a graphical representation of the fiber’s characteristics along its entire length.

Identifying Faults and Reflectance Issues in MPO Trunk Cables

An OTDR identifies faults and reflectance issues within MPO trunk cables. It sends light pulses down the fiber and measures the reflected light. High reflectance often indicates problems. Common causes of high reflectance include:

- Contaminated, damaged, or improperly polished fiber end faces.

- Poorly terminated connectors.

- Faulty fusion splices creating air gaps and core misalignments.

- Cracks, breaks, and open fiber ends.

- Microbends and macrobends resulting from installation stresses.

- Mismatched fiber types with varying construction and core sizes.

An OTDR pinpoints the exact location of these issues, allowing for targeted repairs.

Mapping Fiber Infrastructure with OTDR for MPO Trunk Networks

OTDRs also map the fiber infrastructure in MPO trunk networks. They provide a visual trace showing the location of connectors, splices, and the overall length of the fiber. This mapping helps technicians understand the physical layout of the network. It also assists in documenting the fiber plant for future maintenance and troubleshooting.

Accurate Polarity Verification for MPO Trunk Systems

Accurate polarity verification is critical for MPO trunk systems. Incorrect polarity prevents data transmission.

Tools and Methods for MPO Trunk Polarity Confirmation

Specialized testing equipment verifies MPO trunk polarity in the field. For instance, Fluke Networks’ MultiFiber™ Pro tests individual patch cords, permanent links, and channels. It ensures correct polarity regardless of the chosen MPO polarity method (A, B, or C). These tools confirm that transmit signals align with receive paths.

Troubleshooting Polarity Mismatches in MPO Trunk Deployments

Incorrect MPO trunk polarity leads to significant network problems. When polarity is not correctly maintained, the transmit signal (Tx) at one end does not align with the corresponding receiver (Rx) at the other end. This misalignment results in a non-functional channel, preventing data transmission. Consequences include:

- Downtime and operational inefficiencies.

- Costly troubleshooting efforts.

- Signal misalignment, causing communication failure.

- Cascading failures affecting multiple downstream connections.

- Diagnostic difficulty due to non-visual problems.

- Sensitivity issues in high-speed networks, halting data flow.

- Lost revenue and customer dissatisfaction in critical applications.

Troubleshooting involves re-checking cable types, connector orientations, and ensuring adherence to the chosen polarity scheme.

4. Proactive Maintenance and Monitoring of MPO Trunk Infrastructure

Proactive maintenance and continuous monitoring are essential for sustaining the high performance and reliability of any MPO trunk infrastructure. These practices prevent minor issues from escalating into significant network disruptions. They also extend the lifespan of critical components.

Establishing Regular Inspection Schedules for MPO Trunk Components

Regular inspections form the backbone of a robust maintenance strategy. They help identify potential problems before they impact network operations.

Visual Checks for Damage on MPO Trunk Cables and Connectors

Technicians should conduct routine visual inspections of all MPO trunk cables and connectors. They look for signs of physical damage, such as kinks, cuts, or abrasions on cables. They also check connectors for cracks, bent pins, or other visible defects. Early detection of such damage allows for timely repairs or replacements, preventing unexpected outages.

Periodic Re-cleaning of MPO Trunk Connectors

Contamination remains a primary cause of signal loss in fiber optic networks. Therefore, periodic re-cleaning of MPO trunk connectors is crucial. Technicians should inspect every end face, even brand new ones, before mating. They clean end faces only if inspection reveals contamination. Cleaning itself can attract dust due to static electricity. Lint-free wipes and specific solvent solutions are suitable for cleaning. Avoid using canned air and dusters, as they can spread particles. For MPO connectors, inspect the entire ferrule using a large field of view microscope before inspecting individual fiber end faces. This helps detect 10 μm debris.

Maintaining Optimal Environmental Control for MPO Trunk Performance

Environmental factors significantly influence the longevity and performance of fiber optic components. Proper control minimizes these risks.

Temperature and Humidity Management for MPO Trunk Longevity

Environmental factors like high or low temperatures and humidity levels adversely affect fiber optic performance. It is important to consider these conditions. Implement good practices for cable management and protection. Optimal operating temperatures for fiber optic cables typically range from -25 to +70 °C or -40 to +85 °C. Storage temperatures usually fall between -20 to +70 °C. Maintaining these ranges helps prevent material degradation and signal instability.

Dust and Contaminant Prevention for MPO Trunk Connectors

Dust and other contaminants pose a constant threat to MPO connectors. Dust caps can contain residue from manufacturing. Mating processes can transfer contaminants between end faces. Environmental exposure, especially with static electricity, collects dust on end faces. Improper handling, such as brushing an end face on clothing, transfers oils or lint. Equipment ports are often overlooked sources of contamination. Regularly inspecting and cleaning all plugs and ports before mating helps prevent these issues.

Implementing Robust Documentation and Labeling for MPO Trunk Networks

Comprehensive documentation and clear labeling are indispensable for efficient network management and troubleshooting.

Accurate Port and Cable Identification for MPO Trunk Assemblies

Proper and durable labeling at both ends of cables simplifies troubleshooting for individuals or teams. This saves time during maintenance periods. Clear labeling of each cable allows for easy identification during troubleshooting. Clearly marking each MPO trunk’s polarity, fiber count, and destination helps avoid mis-patching downtime.

Maintaining Up-to-Date Network Diagrams for MPO Trunk Infrastructure

Full documentation, including cable routes, connector types, and performance testing results, is crucial. Thorough testing and documentation of installation details (types, counts, topology) are essential for future reference during scale-ups or similar projects. An easy labeling system for cables and connectors, along with recorded pathways, connector types, device ports, and test results, enables faster troubleshooting during maintenance.

5. Future-Proofing Your MPO Trunk Connectivity

Future-proofing network infrastructure ensures it meets tomorrow’s demands. Strategic planning and adoption of new technologies prevent costly overhauls. This approach guarantees long-term performance and adaptability.

Strategic Scalability Planning for MPO Trunk Deployments

Scalability is crucial for evolving data center needs. Planning for growth from the outset saves significant resources.

Designing MPO Trunk Infrastructure for Future Bandwidth Needs

Designing for future bandwidth requires careful consideration. Low-loss connectors are essential. They maintain signal integrity in high-density, high-speed environments. Fiber count also matters; 12-fiber MPO connectors are common, but 24-fiber or 48-fiber options exist for higher density. Networks must accommodate future growth without costly re-cabling. Correct polarity understanding prevents significant signal loss. Connectors should be robust and simple to install. Proper testing and high-quality connectivity enhance overall network reliability.

Leveraging Modular MPO Trunk Cassettes and Panels

Modular MPO trunk cassettes and panels offer significant advantages. They provide space efficiency. A single MTP/MPO connector can replace many LC/SC connectors, reducing rack space by up to 75%. This is vital for high-density environments. Plug-and-play deployment allows rapid installation. A 144-fiber backbone deploys in minutes, not hours. MTP/MPO technology supports 400G/800G Ethernet, simplifying network upgrades. These modules offer flexibility in configuration. They minimize cable clutter and improve airflow for better cooling.

Adopting Emerging Standards for MPO Trunk Technology

Staying current with industry standards is vital. This prepares networks for the next generation of data transmission.

Preparing MPO Trunk Networks for Higher Speed Ethernet

Higher speed Ethernet demands advanced solutions. Emerging standards include 800G-DR8, which uses eight parallel 100-Gbit transmission channels with PAM4 coding. It often uses Singlemode MPO/MTP 16 connectors. Google’s 800G-PSM8 specification also uses eight parallel 100-Gbit channels with Singlemode MPO/MTP 16. For multimode applications, 800G-SR8 uses eight parallel 100-Gbit channels, often with Multimode MPO/MTP 16 APC 8° connectors. These solutions support high fiber counts and offer rapid installation.

Considering Next-Generation MPO Trunk Connectors and Innovations

Innovations in MPO connectors focus on performance. Modern MPO connectors achieve low insertion loss. They feature advanced alignment systems for accurate core-to-core contact. High-density multi-fiber connections reduce component count, minimizing losses. The quality of finished materials, like ferrules and alignment pin assemblies, impacts performance. Precision polishing and advanced manufacturing processes enhance efficiency. These details ensure an unobstructed optical path, vital for high-speed networks.

Ensuring Vendor Interoperability for MPO Trunk Components

Interoperability guarantees seamless integration. It provides flexibility and avoids vendor lock-in.

Guaranteeing Compatibility Across Equipment with MPO Trunk Assemblies

Ensuring compatibility across equipment is paramount. This allows components from different manufacturers to work together.

Utilizing Standardized MPO Trunk Components for Flexibility

Standardized components offer flexibility. TIA-568 standards establish a foundation for structured cabling systems. They require MPO connectors to meet specific specifications for uniform performance. IEC 61754-7 defines dimensions and operational requirements for MPO connectors. This ensures global compatibility. ISO/IEC 11801 addresses generic cabling for customer premises. It supports high-speed data transmission via fiber optic cables conforming to IEC 61754-7. These standards ensure scalability and integrity within telecommunications infrastructure.

Optimized MPO trunk connectivity critically impacts data center efficiency. Businesses achieve peak performance by strategically selecting cables, ensuring precise installation, and conducting thorough testing. Proactive maintenance and future-proofing further enhance MPO trunk performance. Implement these essential tips to achieve superior data center connectivity and reliability.

FAQ

What is an MPO trunk cable?

An MPO 트렁크 케이블 is a multi-fiber cable. It terminates with MPO connectors on one or both ends. These cables provide high-density connectivity. They are essential for data centers and enterprise networks. They streamline installations and manage large fiber counts efficiently.

Why is polarity crucial in MPO systems?

Correct polarity ensures proper signal flow. It aligns the transmit signal from one device to the receive signal of another. Incorrect polarity causes communication failure. Technicians must verify polarity during installation to prevent network downtime.

What is the difference between single-mode and multi-mode MPO fiber?

Single-mode MPO fiber transmits data over long distances. It uses a small core. Multi-mode MPO fiber supports shorter distances. It has a larger core. Data centers typically use multi-mode for internal links. Telecommunications often use single-mode for longer runs.

기술자는 얼마나 자주 MPO 커넥터를 청소해야합니까?

Technicians should inspect and clean MPO connectors before every mating. Contamination is a leading cause of signal loss. Even new connectors can have debris. Regular cleaning prevents performance degradation and equipment damage.

What is the purpose of an OLTS in MPO trunk testing?

An Optical Loss Test Set (OLTS) measures the total optical power loss. It verifies the insertion loss of an MPO trunk link. This tool confirms signal strength meets industry standards. It ensures the link supports intended applications reliably.

Why is future-proofing important for MPO trunk networks?

Future-proofing ensures the network can handle increasing bandwidth demands. It prevents costly re-cabling projects. Designing with scalability in mind supports future upgrades. This approach extends the network’s lifespan and optimizes investment.

What do plenum and riser ratings mean for MPO cables?

Plenum-rated MPO cables are for air-handling spaces. They produce low smoke and flame. Riser-rated cables are for vertical shafts. They resist flame spread between floors. Selecting the correct rating ensures fire safety and code compliance.