Seemingly minor deviations from specifications and standards significantly impact network reliability, speed, and overall efficiency. These small variances often lead to unexpected bottlenecks and difficult troubleshooting challenges. This blog demystifies critical elements of MPOブレイクアウトハーネスケーブル performance. Understanding these details ensures optimal network operation.

キーテイクアウト

- MPO Breakout Harness Cables connect many fibers into one. They help manage cables in tight spaces.

- These cables support fast internet speeds. This includes 40G, 100G, and 400G Ethernet.

- Fiber type and count matter. Multimode is for short distances, singlemode for long distances.

- Polarity is very important. It makes sure signals go from sender to receiver correctly.

- Insertion Loss and Return Loss show cable quality. Low insertion loss and high return loss are best.

- Good connectors and clean surfaces are key. They stop signal loss and reflections.

- Always use cables that meet standards. Cheap cables cause many problems and cost more later.

- Test cables before and after putting them in. This prevents issues and ensures good performance.

Understanding the MPO Breakout Harness Cable: Core Function and Value

What is an MPO Breakout Harness Cable?

MPO Connectors and Multi-Fiber Arrays

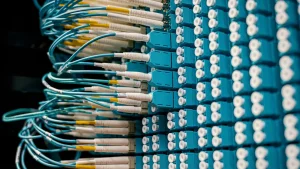

An MPO Breakout Harness Cable represents a sophisticated solution for high-density fiber optic networking. At its core, it features an MPO (Multi-fiber Push On) connector. This connector houses multiple optical fibers within a single ferrule, typically 12, 24, or even 48 fibers. This multi-fiber array allows for compact and efficient fiber management, crucial in environments where space is at a premium. The MPO connector provides a robust and reliable interface for these numerous fibers.

The "Breakout" Function to Individual Connectors (LC, SC, FC)

The "breakout" function defines the cable’s versatility. One end of the MPO Breakout Harness Cable terminates with an MPO connector. The other end "breaks out" into multiple individual connectors, such as LC, SC, or FC. This design allows the cable to:

- Distribute signals to multiple devices.

- Connect equipment to main trunks.

- Simplify complex cabling systems.

- Enhance flexibility in network configurations.

This conversion from a multi-fiber MPO interface to individual simplex or duplex connectors enables customized configurations in high-density environments.

The Performance Promise of MPO Breakout Harness Cables

High-Density Connectivity in Data Centers

MPO Breakout Harness Cables deliver significant advantages in high-density data center applications. They offer a compact footprint, maximizing the use of valuable rack space. This high-density capability is essential for modern data centers, which constantly seek to optimize their physical infrastructure. These cables are used for efficient resource allocation and improve overall network performance. They also offer a cost-effective solution for expanding networks.

Supporting High-Speed Applications (40G, 100G, 400G Ethernet)

These cables are indispensable for supporting high-speed applications. They play a critical role in 40G, 100G, and 400G Ethernet deployments. Their design facilitates the rapid transmission of large volumes of data, meeting the demands of contemporary network architectures. They find use in internal connector applications within fiber equipment, such as Splitters, 40G/100G SFP, and SFP+. This makes them a cornerstone for future-proofing network infrastructure and ensuring seamless operation in demanding environments.

Key Specifications of MPO Breakout Harness Cables: Hidden Performance Drivers

Understanding the detailed specifications of MPO Breakout Harness Cables reveals their true performance capabilities. These specifications are not just technical details; they are critical drivers of network efficiency and reliability.

Fiber Count and Type for MPO Breakout Harness Cables

The selection of fiber count and type for an MPO Breakout Harness Cable directly impacts its suitability for specific network demands.

Multimode vs. Singlemode Fiber

Fiber optic cables come in two primary types: multimode and singlemode. Multimode fibers transmit multiple light modes. They are suitable for shorter distances, typically within a data center or campus environment. Singlemode fibers transmit a single light mode. They are ideal for longer distances and higher bandwidth applications, often used in telecommunications and wide area networks.

OM3, OM4, OM5 vs. OS2 Considerations

MPO cables are available in various fiber counts and types. Common counts include 8, 12, or 24 cores. Newer 16-fiber cables are designed for 400G short-reach cabling in hyperscale data centers. Eight-fiber MTP/MPO cables transmit the same data rates as 12-fiber cables. They offer lower cost and insertion loss. Twelve-fiber MTP/MPO cables were the first and most widely used for 10G-40G and 40G-100G connections. Twenty-four-fiber MTP/MPO cables are often used for connecting CFP-to-CFP transceivers. They are recommended for migration to 40/100/400GbE. Sixteen-fiber MTP/MPO cables combine multiple 8-fiber parallel transceivers. They directly interface with upcoming 16-fiber parallel fiber links like 400G QSFP-DD and OSFP.

Multimode OM3/OM4 MTP/MPO cables are suitable for short-distance transmission (100m or 150m). Single-mode OS2 MTP/MPO cables are ideal for long-distance transmission in MANs and PONs. They offer higher bandwidth due to less modal dispersion. MPO breakout cables (harness or fanout cables) have an MPO/MTP connector on one end and 4/6/8/12 duplex LC/FC/SC/ST connectors on the other. These breakout cables are typically used for short-distance 10G-40G and 25G-100G direct connections. They also connect backbone assemblies to rack systems in high-density cabling.

| 特性 | OM3 | OM4 | OS2 |

|---|---|---|---|

| 波長 | 850nm | 850nm | 1310nm/1550nm |

| Max Transmission Distance | 100m | 150m | 200km |

| 応用 | Buildings, Campus | Buildings, Campus | Carrier Networks, MANs, & PONs |

Polarity Methods for MPO Breakout Harness Cables

Polarity is a critical specification for MPO cabling. It ensures proper signal flow from transmitter to receiver.

Polarity Methods A, B, and C Explained

Different polarity methods (A, B, C) define how fibers arrange within the cable. Polarity Type A maintains a straight-through configuration. Fibers at both ends are in the same order. Type B reverses the fiber order from one end to the other. Type C flips adjacent pairs of fibers. These configurations are crucial for ensuring the correct transmitter communicates with the correct receiver. Incorrect polarity leads to signal transmission in the wrong direction, impeding data flow. A single cable with a different polarity type can alter the entire link’s polarity. This emphasizes the need for careful validation.

Impact on Signal Transmission and Troubleshooting

The choice of polarity method significantly influences network design, especially in high-density MPO wiring systems. Each MPO element (trunk, adapter, patch cord) is classified by type (A, B, or C). It contributes to maintaining the required polarity for end-to-end signal integrity. The ‘connectivity method’ (A, B, or C) refers specifically to the MPO trunk cable type for the entire system. For instance, a Method A connection for parallel signals typically uses a Type A trunk, two Type A mating adapters, a Type A patch cord on one end, and a Type B patch cord on the other. The appropriate polarity type depends on the architecture’s design and equipment requirements. Type A and B are common in data centers and CORDs. Type C is often used in duplex applications.

Different polarity methods impact network design by requiring specific considerations and best practices:

- Use the right adapters: Type B adapters are recommended for discrete connectors (LCs, SCs) with APC. Type A adapters are for MPO connectors, regardless of APC use.

- Consider migration paths: MPO connectors should have pinned trunks and unpinned patches, cassettes, or array cables. This facilitates future equipment migration, especially with QSFP connections.

- Modified Method A for simplex systems: For simplex or asymmetrical systems, modified Method A simplifies deployment. It uses pinned trunks and A:A cords to maintain a 1:1 relationship for port and fiber numbering.

- Modified Method B for duplex systems: For duplex or symmetrical systems, modified Method B (an augmentation to the standard) involves pinned trunks, Type A array adapters, and either inverting port numbering or using a Type A alternate array to ensure a 1:1 relationship.

- Standardize components: Standardizing components is crucial for scalability and maintenance in network design.

Insertion Loss and Return Loss in MPO Breakout Harness Cables

Insertion Loss (IL) and Return Loss (RL) are fundamental performance indicators for fiber optic cables.

Defining Insertion Loss (IL) and its Impact

Insertion Loss (IL) measures the signal power lost when light passes through a connection or a length of fiber. It represents the reduction in optical power from the input to the output. High insertion loss weakens the signal. This limits transmission distance and can cause data errors. Low-loss fiber materials ensure minimal insertion loss, maintaining signal strength over distance.

Defining Return Loss (RL) and Signal Integrity

Return Loss (RL) measures the amount of light reflected back towards the source. It indicates the quality of the connection. Higher RL values mean less light reflects back. High return loss is desirable. It minimizes signal interference and ensures better signal integrity. Poor return loss can lead to signal degradation and increased bit error rates. MPO Breakout Harness Cable designs often feature high return loss (≥50dB). This ensures optimal signal integrity.

Connector Quality and End-Face Geometry of MPO Breakout Harness Cables

The physical quality of connectors and their end-face geometry significantly dictates the performance of fiber optic networks. These elements directly influence how light transmits through the connection.

Importance of Ferrule Quality and End-Face Polish (PC, UPC, APC)

Ferrules are the small, cylindrical components that house and align optical fibers within a connector. Their quality is paramount for achieving precise fiber alignment. The end-face polish refers to the finish applied to the ferrule’s tip, which directly contacts another ferrule when mated. Different polish types exist, each offering distinct performance characteristics:

- PC (Physical Contact): This polish type features a slightly rounded ferrule end-face, which helps reduce air gaps between mated fibers.

- UPC (Ultra Physical Contact): UPC polish offers a more extensive and refined convex surface than PC, resulting in even lower back reflection.

- APC (Angled Physical Contact): APC connectors feature an 8-degree angle on the ferrule end-face. This angle reflects any back-reflected light into the cladding, preventing it from returning to the light source. APC polish provides the best return loss performance.

The choice of ferrule quality and polish type directly impacts insertion loss (IL) and return loss (RL). Higher quality ferrules and superior polish types minimize signal degradation.

| Connector Grade | Max Insertion Loss (dB) | Return Loss (dB) |

|---|---|---|

| 標準 | 0.50 | -30 |

| Low-Loss | 0.35 | n/a |

| Elite | 0.25 | > -60 |

Elite ferrules significantly enhance performance. They can reduce insertion loss by up to 50% compared to standard MPO connectors. Elite MTP connectors maintain return loss above -60 dB. This represents a 30 dB improvement (1000 times less reflected power) compared to standard MPO’s -30 dB.

Microscopic Impact on IL/RL Performance

Even microscopic imperfections on the connector end-face profoundly affect IL and RL performance. These minute details determine how efficiently light passes through a connection and how much light reflects back. The floating ferrule design in MTP connectors offers a mechanical enhancement. It helps maintain consistent physical contact between mated ferrules. This design compensates for minor alignment variations. It also ensures stable insertion loss across mating cycles and under varying environmental conditions, thereby reducing signal degradation.

Several factors contribute to the microscopic impact on IL/RL performance:

- Fiber tip shape

- Fiber tip height variation

- Ferrule surface shape and angular orientation relative to guide pin bores

- Best fit fiber tip line angles relative to guide pin bores

- Ferrule material properties

- Guide pin material properties

Each of these elements must meet stringent specifications to ensure optimal performance for an MPO Breakout Harness Cable. Deviations in any of these microscopic aspects can lead to increased insertion loss, reduced return loss, and ultimately, compromised network reliability and speed.

MPO Breakout Harness Cable Standards: Blueprint for Reliability

TIA/EIA Standards for MPO Breakout Harness Cables

The Telecommunications Industry Association (TIA) and Electronic Industries Alliance (EIA) establish crucial standards for fiber optic cabling. These guidelines ensure interoperability and reliable performance.

TIA-568.3-D and Polarity Specifications

TIA-568.3-D, a key standard, outlines specifications for optical fiber cabling and components. It includes detailed polarity requirements for MPO systems. Components like connectors, cables, and cassettes must comply with TIA-568 and IEC 61754-7. This ensures proper performance and interoperability, especially regarding polarity management. For 24-fiber specific infrastructure, polarity adheres to TIA standards, specifically Types C and D, for duplex applications. The ANSI/TIA-568.3 Optical Fiber Cabling and Components Standard is undergoing revision. It will include a Type “U” (Universal) polarity. This update aims to simplify fiber paths and resolve gender conflicts in multi-manufacturer fiber environments. An MPOブレイクアウトハーネスケーブル supports Type A, B, or C polarity.

- Type A (straight-through): Fiber position 1 connects to position 1 at the far end. The connector key orientation flips (key-up on one end, key-down on the other). This requires mixed patch cord types for proper Tx/Rx alignment.

- Type B (reversed): Both connectors are key-up. This results in a complete fiber reversal (position 1 arrives at position 12). This method is preferred for direct transceiver-to-transceiver parallel optic links, such as SR4, DR4, and DR4+ applications.

- Type C (pair-flipped): Fibers swap in adjacent pairs (e.g., 1↔2, 3↔4). This is suitable for duplex breakout scenarios but generally not recommended for parallel optics in new deployments.

Performance Limits and Cabling Components

TIA standards define strict performance limits for all cabling components. These limits cover insertion loss, return loss, and mechanical durability. Adherence to these specifications guarantees the reliability and longevity of fiber optic networks.

IEC Standards for MPO Breakout Harness Cables

The International Electrotechnical Commission (IEC) provides global standards for electrical and electronic technologies. These standards are vital for MPO components.

IEC 61754-7 (MPO Connector Interface)

IEC 61754-7 specifies the MPO connector interface. This standard ensures physical compatibility among MPO connectors from different manufacturers. It defines critical dimensions and mechanical properties. This allows for seamless mating and reliable connections.

IEC 61755 (Connector Optical Interfaces)

IEC 61755 addresses the optical interfaces of fiber optic connectors. It sets performance requirements for parameters like insertion loss and return loss. This standard ensures connectors meet specific optical performance criteria. It contributes to overall network signal integrity.

IEEE Standards and MPO Breakout Harness Cable Applications

The Institute of Electrical and Electronics Engineers (IEEE) develops standards for Ethernet technologies. These standards dictate the requirements for high-speed data transmission.

40GBASE-SR4 and 100GBASE-SR4 Requirements

IEEE standards like 40GBASE-SR4 and 100GBASE-SR4 define the physical layer specifications for high-speed Ethernet. These standards often mandate parallel optics. They rely on MPO interfaces for their multi-fiber capabilities. For example, 40GBASE-SR4 uses four fibers for transmit and four for receive.

Fiber Count and Performance for Ethernet Standards

IEEE standards specify the required fiber count and performance characteristics for various Ethernet speeds. These requirements ensure that the cabling infrastructure supports the intended data rates without bottlenecks. MPO technology provides the necessary fiber density and performance to meet these demanding Ethernet standards.

The Surprising Truths: Common Pitfalls with MPO Breakout Harness Cables

Even with meticulous planning, certain pitfalls can undermine the performance of MPO Breakout Harness Cables. Understanding these common issues helps network administrators avoid costly mistakes and ensure robust network operation.

The Polarity Mismatch Trap

Why "Plug and Play" Can Fail

The "plug and play" promise of MPO systems sometimes falls short due to polarity mismatches. Fiber optic systems require a transmit (Tx) connection to align precisely with a receive (Rx) connection at the other end. MPO connectors do not automatically manage this polarity. While TIA-568 defines three polarity methods (Type A, Type B, Type C), a mismatch occurs when the chosen cable type does not align with the equipment’s requirements or the overall cabling scheme. This misalignment prevents proper signal flow, leading to communication failures despite physically connected cables.

Real-World Scenarios and Troubleshooting

Polarity mismatches in MPO breakout harness cables directly impact connectivity and performance in fiber optic systems. When polarities are mismatched, signals can be lost, data transmission rates may decrease, or error rates might increase. This issue becomes more critical in dense networks, where even minor misalignments can severely degrade performance. For multi-fiber systems like MPOs, incorrect configuration due to polarity issues can result in no link or poor performance. Troubleshooting these issues is significantly harder, requiring extensive testing and reconfiguration, which leads to longer downtimes and increased operational costs. This risk can be mitigated by using pre-tested, factory-configured cables and employing polarity testers with automated documentation tools. Most 40G/100G QSFP transceivers typically use Type B breakout cables. However, it is crucial to always verify the required polarity with the transceiver datasheet, as incorrect polarity can lead to network failures that are often resolved by simply rotating a connector.

Overlooking Insertion Loss Budgets

Cumulative Loss and Signal Degradation

Network designers often overlook the cumulative effect of insertion loss across an entire fiber optic link. Each connection point, splice, and length of fiber contributes to the total insertion loss. While individual components may meet specifications, the sum of these losses can exceed the network’s allowable budget. This cumulative loss weakens the optical signal, reducing its strength below the receiver’s sensitivity threshold. Consequently, the network experiences signal degradation, leading to unreliable data transmission.

Intermittent Issues and Performance Bottlenecks

Exceeding the insertion loss budget often manifests as intermittent network issues. These problems are difficult to diagnose because they do not always result in complete link failure. Instead, they cause sporadic packet loss, reduced throughput, or increased latency. Such performance bottlenecks hinder application efficiency and user experience. They also create significant troubleshooting challenges, as the underlying cause is not immediately apparent. Careful calculation of the total insertion loss budget for every link is essential to prevent these subtle yet impactful performance degradations.

The "Cheap Cable" Conundrum for MPO Breakout Harness Cables

Risks of Non-Compliant Products

The allure of lower costs sometimes leads to the procurement of non-compliant or low-quality MPO Breakout Harness Cable products. These cables often fail to meet industry standards for performance, durability, and safety. They may use inferior fiber, connectors, or manufacturing processes. Such products introduce significant risks into a network infrastructure. They compromise signal integrity and overall system reliability.

Hidden Costs of Poor Performance and Unreliability

Deploying non-compliant or low-quality MPO breakout harness cables in a data center environment introduces numerous hidden costs and risks:

- Safety Hazards and Liability Risks:

- Messy cables create trip hazards, increasing workplace injury risks and potential workers’ compensation claims or lawsuits.

- Poor cable practices can lead to fines and increased insurance premiums due to non-compliance with OSHA regulations.

- Cables running across power connections create shock hazards. Damaged cables can cause equipment failures or electrical fires, identified by the NFPA as a leading cause of data center fires.

- Equipment Damage and Reduced Lifespan:

- Improperly managed cables create physical stress on equipment ports and connectors, potentially damaging motherboard connections and requiring expensive repairs or replacements.

- Cables bent beyond their minimum bend radius suffer internal damage, degrading signal quality and reliability.

- When power and data cables run parallel without proper separation, electromagnetic interference (EMI) can cause network errors, data corruption, and intermittent connectivity issues.

- Environmental stresses from poor cable management (e.g., hot spots from blocked airflow) accelerate equipment depreciation, leading to higher failure rates and more frequent replacements.

- Manufacturers may deny warranty coverage for equipment damaged by excessive heat or physical stress due to poor cable management, forcing organizations to absorb replacement costs.

- Network Performance Degradation:

- Poorly terminated or contaminated fiber connectors lead to increased attenuation, resulting in weaker signals and degraded data transmission quality.

- Improperly installed fiber can introduce excessive latency, disrupting real-time applications.

- Subpar fiber management leads to greater optical signal degradation, increasing the frequency of transmission errors and network instability.

- Operational Inefficiencies:

- Poor fiber installations require ongoing troubleshooting and corrective work, increasing maintenance costs and downtime.

- Messy and unstructured cabling complicates fault identification, leading to prolonged resolution times for network failures.

- Substandard installations often result in incompatible infrastructure, requiring rework and delaying capacity expansions.

- Energy and Sustainability Issues:

- Dense and unorganized fiber cabling obstructs airflow, leading to higher cooling demands and energy inefficiency.

- Poorly optimized network components consume more power, undermining sustainability initiatives.

- Frequent failures due to improper installations contribute to electronic waste.

- Financial Implications:

- Poorly installed fiber requires more frequent repairs, driving up maintenance expenses and long-term capital investment.

- Supply chain bottlenecks often necessitate expensive expedited shipping for critical components, increasing overall infrastructure costs.

- Persistent performance issues lead to SLA violations, reduced customer confidence, and financial penalties.

These hidden costs far outweigh any initial savings from purchasing cheaper, non-compliant cables. They ultimately lead to increased operational expenses, reduced network reliability, and potential financial losses.

Best Practices for MPO Breakout Harness Cable Deployment

Deploying MPO Breakout Harness Cables effectively requires careful planning and execution. Adhering to best practices ensures optimal performance and longevity for network infrastructure.

Strategic Planning and Cable Selection

Matching Cables to Network Requirements

Strategic planning begins with selecting the right cables. Designers must evaluate current and future bandwidth needs. This determines the necessary core count, such as 12-core for high-density applications. The type of fiber is also crucial. Single-mode fiber suits long-distance, low-loss transmissions in campus networks. Multimode fiber provides higher bandwidth over shorter distances within data centers. Connector configurations, like MTP/MPO-8, MPO-12, or MPO-24, must be compatible with equipment. Cable length and routing should reduce clutter and prevent signal degradation. MPO cables typically range from 8 to 144 fibers, with MPO-12 and MPO-24 being common.

Considering Future Scalability

Network architects must plan for future scalability. MPO systems support dynamic and growing network architectures. They allow expansion without major infrastructure changes. They also enable easy adjustment of capacities. MTP fiber cables are crucial for high-density networks. They support high-speed data transmission for 40G, 100G, 200G, 400G, and 800G applications. Planning for future speed migrations with clear upgrade paths is essential. Modular and reconfigurable systems allow for easy upgrades and reconfiguration. They also provide quick capacity expansion and standardized polarity management to prevent errors. Balancing performance with cost-effectiveness is key. This considers initial capital outlay versus future operational flexibility and upgrade expenses.

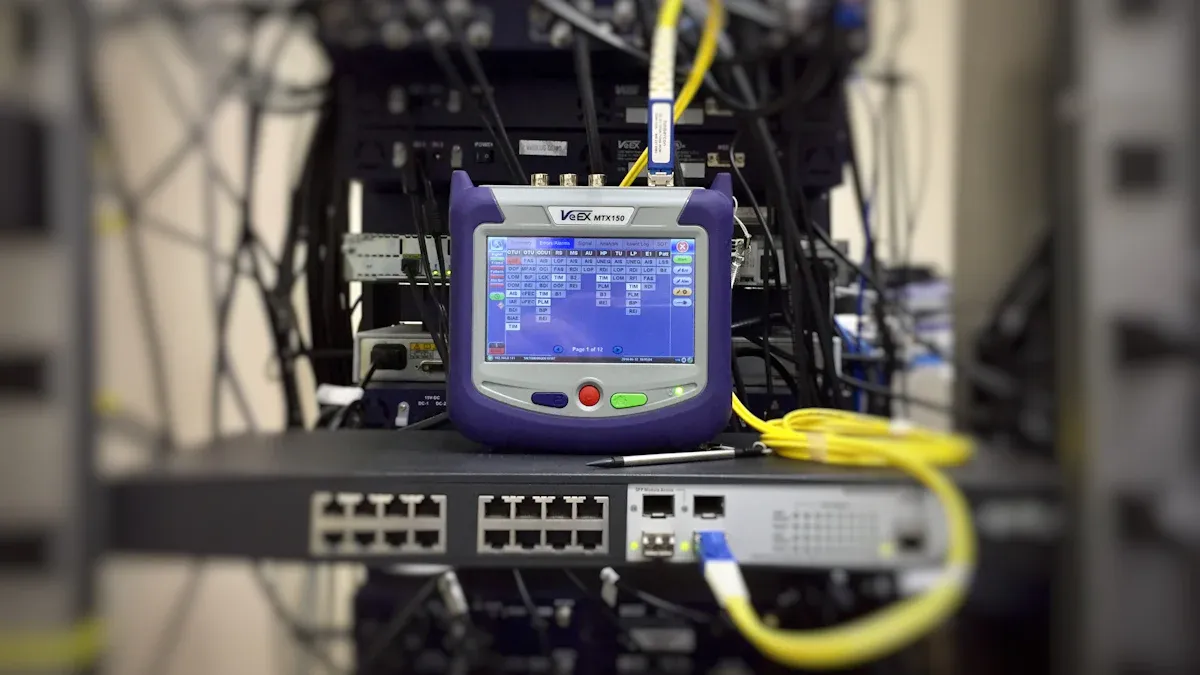

Rigorous Testing and Validation

Ensuring Performance from Day One

Rigorous testing and validation are critical. They ensure optimal performance from the moment of deployment. This proactive approach prevents costly downtime and troubleshooting later.

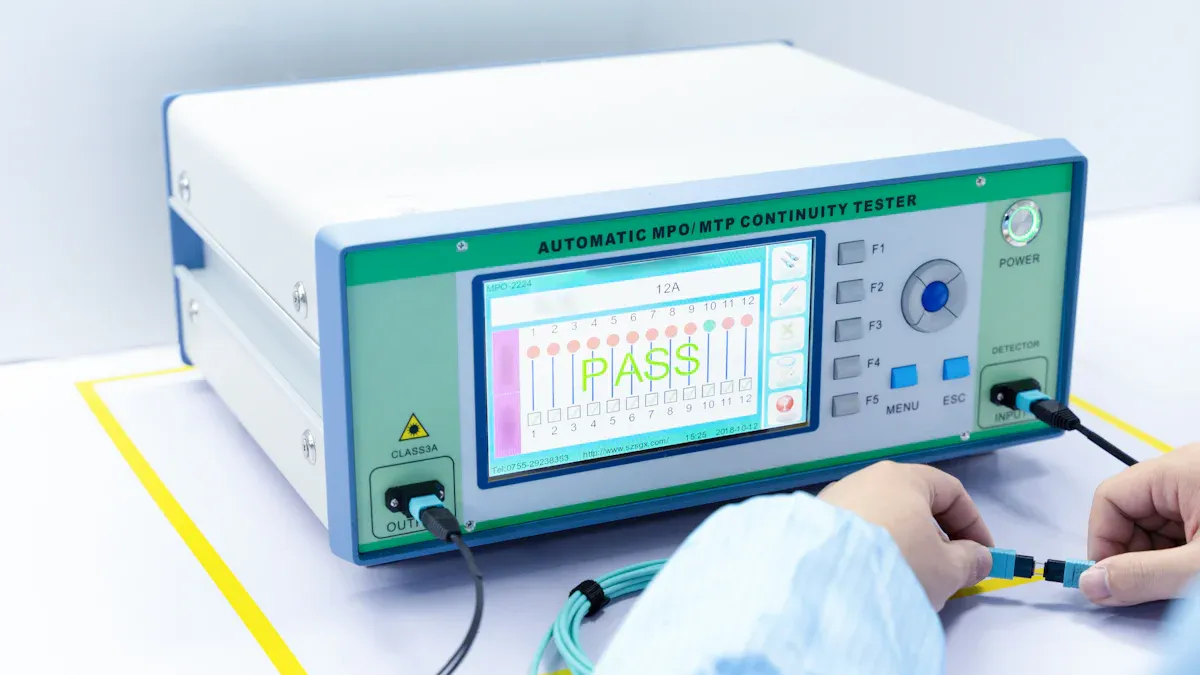

Pre-Deployment and Post-Installation Checks

Pre-deployment considerations include cleaning and inspection. Always clean and inspect MPO end-faces. Contamination significantly impacts performance due to high fiber density. Polarity verification is also essential. Do not assume polarity will work; verify cable types, patch cord types, and the entire channel. Post-installation, Tier 1 testing uses an Optical Loss Test Set (OLTS) with MPO-specific test cords. This measures insertion loss across the channel. Tier 2 testing adds Optical Time-Domain Reflectometer (OTDR) analysis. This identifies loss events like connectors, splices, or bends. Independently verify polarity post-installation using test sets with polarity mapping features.

Proper Handling and Maintenance

Importance of Connector Cleaning

Proper handling and maintenance extend cable lifespan. Connector cleaning is paramount. Dust and contaminants are significant threats. MPO connectors require specialized cleaning due to their larger rectangular ferrule, guide-pins, and multiple fiber ends. Technicians should use dedicated cleaning tools. These include one-click cleaners, cassette cleaners, and lint-free wipes with optical-grade solvents. Always inspect the connector end-face using an inspection microscope before and after cleaning.

Extending Cable Lifespan and Preventing Damage

Extend cable lifespan by preventing damage. Always keep dust caps on connectors when not in use. Handle connectors by their housing to avoid transferring oils. Control the environment by using anti-static mats and air purifiers. Provide regular training to staff on correct cleaning methods. Conduct periodic inspections using fiber scopes. Secure connectors and cables. Verify full seating and latching of connectors. Protect cables from physical damage. Avoid bending, twisting, or pulling MPO cables. Adhere to the minimum bend radius. Properly coil and store excess cable. Monitor environmental factors like temperature and humidity. Stable environments (18-27°C) minimize thermal stress.

Advanced Considerations for MPO Breakout Harness Cables

Adapting to Evolving Data Rates

Support for 400G and Beyond

MPO connectors are optimally suited for 400G applications. They offer high bandwidth and lower loss. These features are critical for efficient data transfer. They also support the continuous development and expansion of network capabilities. This addresses the industry’s growing need for throughput and low latency. The より高速なデータ伝送速度に対する需要の高まり drives this need. Cloud computing, big data analytics, and AI applications are key drivers. This necessitates the adoption of higher fiber count MPO connectors and cables. This trend pushes the boundaries of density and performance in network infrastructure.

MPO-16 cables, for example, consolidate 16 fibers. They support up to 16 connections per connector for increased density. This enables 400Gbps links using 8 Tx and 8 Rx fibers. They support 400G and higher, including 800GbE systems. These cables are fundamental for ultra-high-speed Ethernet (400GBASE-SR8). MMC-16 cables support 2x400G, 800G, 1.6T, and future 3.2T applications. They offer 33% higher port density than 12-fiber MPOs. This reduces costs and optimizes data aggregation for lower latency. They are designed for AI, 5G-Advanced, and quantum computing demands. They integrate as a high-capacity backbone for private 5G. As IBM’s VP of Cloud Infrastructure, Dr. Sarah Aerni, notes, "MPO 16 isn’t just about density—it’s the foundation for rearchitecting exascale systems with photonic determinism."

将来を見据えたネットワーク インフラストラクチャ

The increasing use of parallel optics in high-speed networking directly increases the reliance on MPO connectors. This includes 400GbE and 800GbE. They allow for simultaneous transmission of multiple optical signals. Enhancements in fiber technology, such as bend-insensitive fibers and low-loss connectors, improve the reliability and performance of MPO trunk cable assemblies. This enables more flexible routing in constrained environments. This parallel optics transmission significantly boosts data throughput for AI workloads. Meta’s RSC-2024 AI SuperCluster uses 16,384 MPO-16 cables. These cables connect 24,576 NVIDIA GB200 GPUs. This results in a 28-ton reduction in cabling mass. Ericsson’s Streetmacro 6705 radios employ waterproof MPO-16 cables for 25G eCPRI interfaces. They support Verizon’s 2024 C-band rollout with less than 50 μs latency.

Scalability and Flexibility in Data Centers

High-Density Rack and Panel Solutions

MPO Breakout Harness Cable is essential for high-density and efficient space utilization in modern data centers. They achieve this by breaking out high-density fiber trunks into individual connections. This facilitates organized patching and flexible device aggregation. This design simplifies cable management. It also supports modular patch panel deployments. This reduces the need for additional patch panels. It saves valuable rack space.

効率的なスペース使用率

MPO breakout harness cables enable seamless integration with existing legacy equipment. This allows for phased transitions to higher speeds. It does so without disrupting operations. Their compact design and ability to consolidate multiple fibers into a single connector optimize space. This is crucial in crowded data center environments.

MPO Breakout Harness Cables in Next-Gen Architectures

Role in Cloud Data Centers

MPO/MTP connectors are integrated into next-generation architectures. This includes cloud data centers and high-performance computing environments. They support NVIDIA’s NVLink and Infiniband networks across data center racks for AI and HPC. Hyperscale data centers specifically prefer 24-fiber trunks. This future-proofs their cable plants for 400G/800G rollouts. They rely on pre-terminated MPO trunks for high-density, modular cabling architectures. This includes 24/48-fiber backbones and leaf-spine switch designs.

High-Performance Computing Environments

MPO breakout harness cables play a vital role in high-performance computing (HPC) environments. They support NVIDIA’s NVLink and Infiniband networks in data centers for AI and HPC. They use pre-terminated MPO trunks for high-density, modular cabling architectures in hyperscale and colocation data centers. This includes the implementation of 24/48-fiber backbones and leaf-spine switch designs in these environments. Hyperscale data centers prefer 24-fiber trunks. This prepares them for future 400G/800G rollouts. Enterprises retrofit legacy cabling with MPO trunks and breakout fanouts. This connects high-speed switches to multiple racks. It uses fewer cables and shorter runs.

Ensuring Quality and Compliance for MPO Breakout Harness Cables

The Importance of Reputable Suppliers

Quality Assurance and Certification

Choosing a reputable supplier for network components is crucial. Reputable suppliers provide peace of mind through robust quality assurance and certifications. They hold certifications like ISO 9001, CE, RoHS, and FCC. These certifications confirm their commitment to quality and environmental standards. They also perform rigorous industrial product testing. This includes 3D Interferometer Tests, End-Face Inspections, and Insertion Loss and Return Loss Testing. Furthermore, reputable suppliers employ technicians certified by organizations such as BICSI and FOA. This demonstrates proper training in handling delicate fibers and adherence to industry standards. Their quality assurance processes include adherence to IEC and TIA/EIA standards, thorough connector testing and cleaning, and precise polarity type verification. They also conduct fiber continuity tests, use light sources and optical power meters for signal power and insertion loss, and perform OTDR testing. For multimode MTP/MPO trunk cables, they often provide ANSI/TIA-568-C certification, requiring Method B and a 3-jumper reference for accurate measurement.

Avoiding Counterfeit or Substandard Products

The market sometimes offers cheaper, non-compliant products. Avoiding these counterfeit or substandard items is essential. Such products often lack proper certifications and rigorous testing. They can lead to unpredictable performance, frequent network failures, and increased troubleshooting time. Investing in quality from a reputable supplier prevents these costly issues. It ensures the long-term reliability and efficiency of the network infrastructure.

Factory Termination and Testing

Benefits of Pre-Terminated Solutions

Factory-terminated MPO Breakout Harness Cable solutions offer significant advantages over field termination. They provide overall reliability. Factory-terminated cables are less prone to human error and undergo higher quality control. This results in more reliable connections. They also ensure consistency and repeatability. All cables are made in the same way, often in ISO-certified facilities, guaranteeing consistent connector quality and performance. These solutions are plug-and-play. They reduce installation time significantly compared to field termination and splicing. Factory-terminated cables are also more durable. They are less likely to suffer damage during installation. This contrasts with field-terminated connectors, which are vulnerable to dust, moisture, and environmental factors. Ultimately, factory-terminated cables are more cost-effective in the long run. They eliminate the need for additional tools and equipment required for field termination.

100% Tested for Optimal Performance

Factory-terminated cables undergo thorough testing and quality control. This ensures high quality and performance for the optical link. Factory-terminated connectors typically have lower insertion loss values than field-terminated connectors. This is because they are made in a controlled environment and undergo rigorous quality control testing. For instance, a factory-terminated standard LCUPC connector typically has an insertion loss of around 0.3dB (Max) per connector. Factory terminations offer greater consistency, reliability, and save time in the field. This leads to more cost-efficient solutions. For MTP or MPO connectors, factory termination is generally recommended due to their complexity and the specialized expertise required. Factory-polished assemblies deliver the best performance and adhere to more stringent quality standards than field terminations. This makes them ideal for applications demanding low loss and high performance. Most factory-terminated assemblies also include manufacturer’s test results, guaranteeing quality and excellent performance. These solutions significantly reduce installation time. They arrive ready for immediate use. Technicians only need to remove the ferrule protection cap and clean the connector end face before plugging the assembly into the correct port. This requires minimal technical knowledge.

Understanding and adhering to MPO Breakout Harness Cable specifications and standards is crucial. This knowledge directly translates to predictable, high-performing, and reliable network infrastructure. To unlock the full potential of MPO technology, network professionals must focus on:

- Informed selection

- 適切な取り付け

- Rigorous testing

Avoiding the "surprising truths" of underperformance is key to achieving network success.

よくある質問

What is an MPO Breakout Harness Cable?

An MPOブレイクアウトハーネスケーブル connects a multi-fiber MPO connector to several individual connectors like LC or SC. It enables high-density fiber management. This cable efficiently distributes signals from backbone cabling to various network devices.

Why is polarity crucial for MPO cables?

Polarity ensures correct signal flow from a transmitter to a receiver. Mismatched polarity prevents proper communication. It leads to network failures. Adhering to TIA-568 polarity methods (A, B, C) guarantees signal integrity.

What do Insertion Loss (IL) and Return Loss (RL) mean?

Insertion Loss (IL) measures signal power reduction across a connection. Lower IL is better. Return Loss (RL) indicates light reflected back to the source. Higher RL is desirable. Both metrics are critical for signal integrity.

How do MPO cables support high-speed Ethernet?

MPO cables provide the high-density, multi-fiber connectivity required for 40G, 100G, and 400G Ethernet. They facilitate parallel optics transmission. This enables rapid data transfer in demanding network environments like data centers.

What are the risks of using non-compliant MPO cables?

Non-compliant MPO cables often lead to unpredictable performance, frequent network failures, and increased troubleshooting. They can cause signal degradation, equipment damage, and higher operational costs. Quality cables ensure network reliability.

What are the benefits of factory-terminated MPO solutions?

Factory-terminated MPOソリューション offer superior reliability and consistent performance. They reduce installation time and human error. These cables undergo rigorous testing, ensuring lower insertion loss and optimal signal quality from deployment.

Which MPO polarity methods are commonly used?

Common MPO polarity methods include Type A (straight-through), Type B (reversed), and Type C (pair-flipped). Each method defines fiber arrangement. Network designers select the appropriate type based on equipment and architecture requirements.